Preparation method of wood liquefied product spinning solution

A spinning solution and liquefaction technology, which is applied in the field of wood liquefaction spinning solution preparation, can solve the problems of high pollution and strong pungent odor of phenol, achieve high utilization rate of wood, low temperature range, and improve the overall comprehensive The effect of exploiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

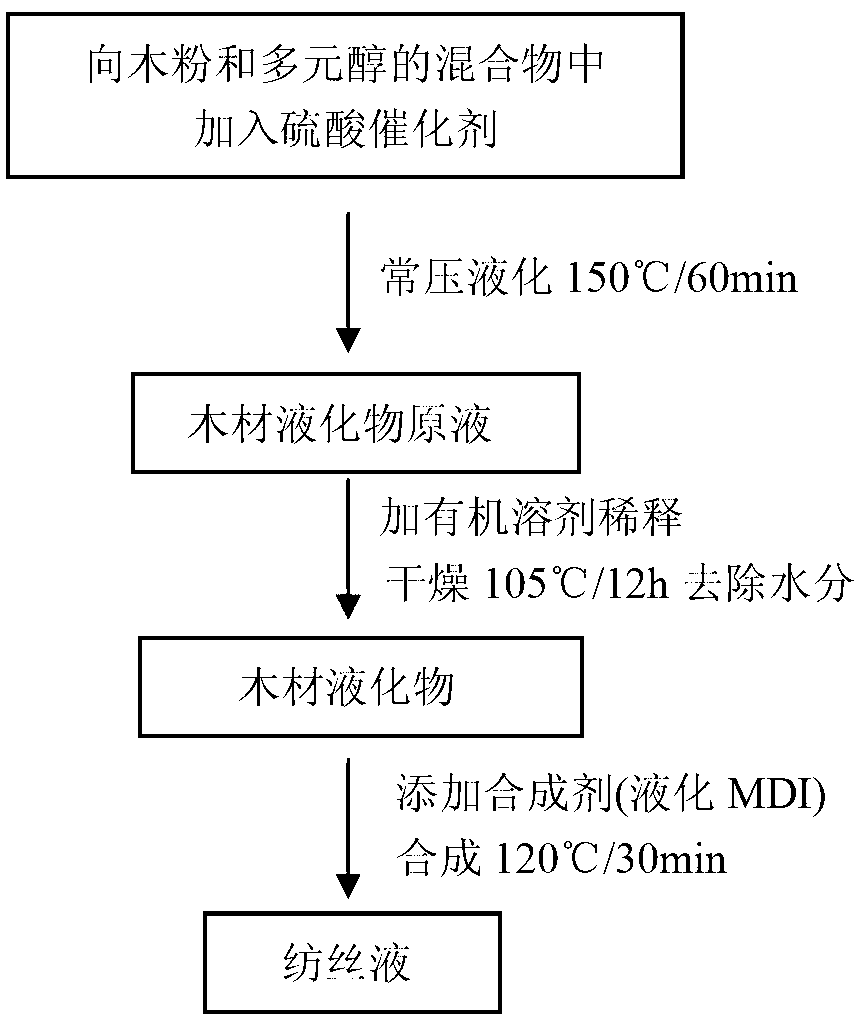

[0025] Embodiment 1 Preparation of wood liquefaction spinning solution

[0026] Grind the wood through a 80-mesh sieve (mesh diameter 0.20mm) wood powder, dry the wood powder and its 1.5 times the weight of polyethylene glycol (PEG400) and glycerol polyol mixture (polyethylene glycol and propylene glycol) The weight ratio of triols is 7:3) and mixed, and at the same time, add sulfuric acid with a concentration of 72% as a catalyst (the amount of sulfuric acid added is 5% of the weight of polyols) to a three-necked flask, and place it in an oil bath with a preheating value of 150°C , install the condensing device, start the agitator (rotating speed 120rpm), carry out wood liquefaction, liquefaction time 60min, obtain the stock solution of wood liquefaction.

[0027] Add 40% dimethylformamide according to the weight ratio of the wood liquefaction stock solution for dilution, place it in a blast drying oven, and dry it at 105°C for 12 hours to remove moisture. Then add carbodiim...

Embodiment 2

[0028] Embodiment 2 Preparation of wood liquefaction spinning solution

[0029] Grind the wood through a 60-mesh sieve (mesh diameter 0.30mm), dry the wood powder and its 2 times the weight of polyethylene glycol (PEG1000) and glycerol polyol mixture (polyethylene glycol and propylene glycol) The weight ratio of triols is 7:3) and mixed, and at the same time, add sulfuric acid with a concentration of 72% as a catalyst (the amount of sulfuric acid added is 5% of the weight of the polyol) into the three-necked flask, and place it in an oil bath with a preheating value of 150°C In the process, the condensing device was installed, and the stirrer was started (rotating speed 120rpm) to carry out wood liquefaction, and the liquefaction time was 60min to obtain a liquefied product.

[0030] Add 40% dimethylacetamide according to the weight ratio of the wood liquefaction stock solution for dilution, place it in a blast drying oven, and dry it at 105°C for 12 hours to remove moisture. ...

Embodiment 3

[0031] Embodiment 3 Preparation of wood liquefaction spinning solution

[0032] Wood is ground into wood powder with a 40-mesh sieve (mesh diameter 0.20mm), and after drying, the wood powder is mixed with a polyol mixture of polyethylene glycol (PEG400) and glycerin (polyethylene glycol and glycerin) twice its weight. The weight ratio of triols is 7:3) and mixed, and at the same time, add sulfuric acid with a concentration of 72% as a catalyst (the amount of sulfuric acid added is 3% of the weight of polyols) into a three-necked flask, and place it in an oil bath with a preheating value of 150°C In the process, the condensing device was installed, and the stirrer was started (rotating speed 120rpm) to carry out wood liquefaction, and the liquefaction time was 60min to obtain a liquefied product.

[0033] Add 40% dimethyl sulfoxide according to the weight ratio of the wood liquefaction stock solution for dilution, then place it in a blast drying oven, and dry it at 105°C for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com