Straw liquefied coating liquid and preparation method and application thereof

A technology of straw and coating, applied in application, fertilizer mixture, fertilization device, etc., can solve the problem of unavoidable uniform mixing of mixture, achieve the effect of accelerating in-situ reaction speed, good controlled release performance, and avoiding negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, the preparation of straw liquefaction coating solution and its controlled-release fertilizer

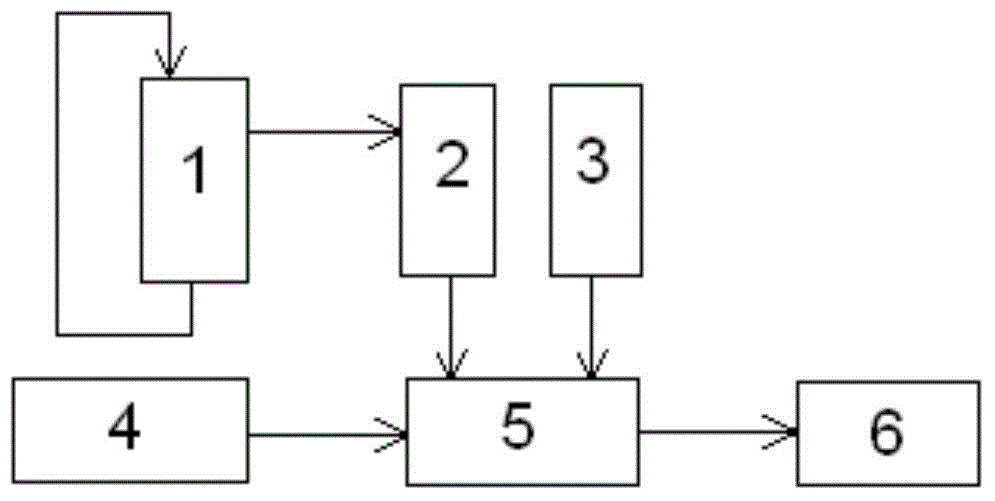

[0050] as per figure 1 The process shown in the preparation of straw liquefaction coating liquid and its controlled-release fertilizer, the specific steps are as follows: 100g of corn stalk powder with a particle size of 80 mesh, a liquefaction agent consisting of 350g of polyethylene glycol 400 and 50g of glycerin, and 8g of concentrated sulfuric acid Acidic catalyst composed of 1.7g tungsten trioxide and 1.3g surfactant Tween-80, mixed evenly in a reaction kettle equipped with mechanical stirring and condenser tube, heated to 160°C under constant stirring, and reacted at constant temperature for 60 minutes , then stop the reaction by cooling in an ice-water bath, filter and remove the residue in the liquefied product, the resulting 450g liquid is the straw liquefied product, and the residue returns to continue liquefaction; add 22.5g of auxiliary microcrystalli...

Embodiment 2

[0052] Example 2, Preparation of Straw Liquefaction Coating Solution and Controlled Release Fertilizer

[0053] as per figure 1 The process shown in the preparation of the straw liquefaction coating solution and its controlled release fertilizer, the specific steps are as follows: 100g of rice straw powder with a fineness of 40 mesh, a liquefaction agent consisting of 200g of polyethylene glycol 200 and 50g of ethylene glycol, and 6g of The catalyst composed of sulfuric acid and 1.5g of tungsten trioxide and 0.5g of surfactant Tween-20 were mixed evenly in a reaction kettle equipped with mechanical stirring and condenser, then the temperature was raised to 180°C under constant stirring, and the reaction was carried out at constant temperature for 40 minutes. , then stop the reaction by cooling in an ice-water bath, filter out the residue in the liquefied product, and obtain 300 g of liquid as straw liquefied product, and return the residue to continue liquefaction; add 9 g of ...

Embodiment 3

[0055] Example 3, Preparation of Straw Liquefaction Coating Liquid and Controlled Release Fertilizer

[0056] as per figure 1 The process shown in the preparation of straw liquefaction coating liquid and its controlled release fertilizer, the specific steps are as follows: 100g fineness of 60 mesh peanut shell powder, liquefaction agent composed of 490g polyethylene glycol 600 and 110g diethylene glycol, 9g A catalyst composed of sulfuric acid and 2g of tungsten trioxide and 1.7g of surfactant Tween-60 was mixed evenly in a reaction kettle equipped with mechanical stirring and a condenser tube, then the temperature was raised to 140°C under constant stirring, and the reaction was carried out at a constant temperature for 120 minutes. Then stop the reaction by cooling in an ice-water bath, filter and take out the residue in the liquefied product, the obtained 630g liquid is the straw liquefied product, and the residue returns to continue liquefaction; add 63g of auxiliary agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com