Method for producing liquefied natural gas by multi-component refrigerant double-stage compression

A technology for liquefied natural gas and refrigerants, applied in refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems of complex process, low unit energy consumption, and many equipment, and achieve the advantages of simple liquefaction process, wide application range, and high liquefaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific implementation examples, but the present invention is not limited only to the examples described below.

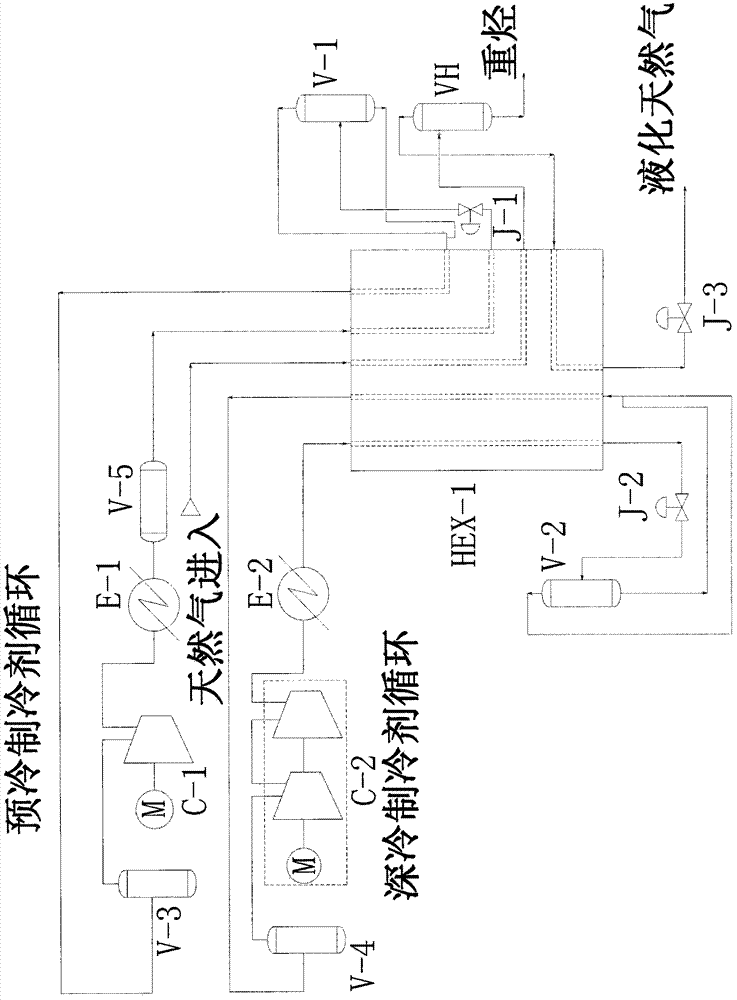

[0023] figure 1 In the shown embodiment, the device used in the method of producing liquefied natural gas by two-stage compression of multi-component refrigerant includes a separation tank V-3, a pre-cooling compressor C-1, a cooler E-1, a buffer tank V- 5. Throttle valve J-1, separation tank V-1, separation tank V-4, cryogenic compressor C-2, cooler E-2, throttle valve J-2, separation tank V-2, separation tank VH, throttle valve J-3, cold box HEX-1.

[0024] The pretreated natural gas (or gas field gas, coal bed methane and gas rich in methane) of about 4.0MPaG enters the cold box HEX-1, and after heat exchange with the precooling refrigerant and cryogenic refrigerant, the temperature reaches about -60°C to become The gas-liquid is mixed, and then it goes out of the cold box HEX-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com