Method for efficiently preparing biological oil by liquefying with water-hydrogen donor mixed solvent

A technology of mixing solvent and bio-oil, which is applied in the preparation of liquid hydrocarbon mixture, petroleum industry, processing of hydrocarbon oil, etc., to achieve the effects of low reaction pressure, mild liquefaction conditions, and widening and diversified utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Raw material preparation

[0031] Take the bagasse that has been accumulated and stored outside the Pumiao Paper Mill of Nanning Sugar Industry Co., Ltd. for more than 1 year. It is dried in the sun, pulverized, passed through a 20-80 mesh sieve, and dried at 110° C. for 24 hours.

[0032] (2) Liquefaction experiment

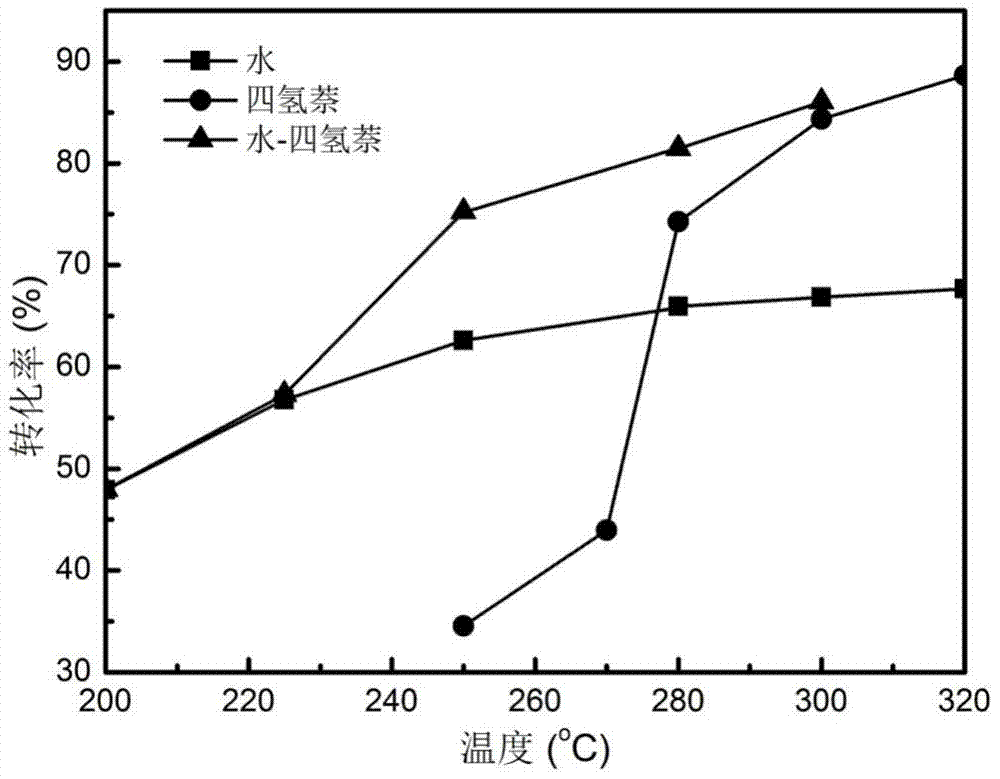

[0033] 1. Using water, tetrahydronaphthalene and water-tetrahydronaphthalene mixed solvent (water / tetrahydronaphthalene mass ratio is 1:1) as the liquefaction medium respectively, add 30 grams of dry bagasse and 240 grams of liquefaction solvent into the reaction kettle together, After evacuating the air in the kettle with hydrogen for 3 times, raise the temperature to the predetermined reaction temperature of 200-320℃ at a heating rate of 5°C / min, and liquefy at a constant temperature for 1.5 hours under the condition of a stirring rate of 300rpm; after the reaction, the reaction kettle is cooled to room temperature. Slowly open the exhaust valve ...

Embodiment 2

[0035] (1) raw material preparation: with embodiment 1.

[0036] (2) Liquefaction experiment

[0037]Dry 30 grams of bagasse and 240 grams of water-tetrahydronaphthalene mixed solvent (water / tetrahydronaphthalene mass ratio is respectively 1:0, 9:1, 1:1, 1:9, 1:14 and 0:1) together Put it into the reaction kettle, use hydrogen to evacuate the air in the kettle for 3 times, raise the temperature to the predetermined reaction temperature of 300°C at a heating rate of 5°C / min, and liquefy at a constant temperature for 0.8 hours under the stirring condition of 300rpm. The steps after the reaction are the same as in the example 1. Experimental result shows: when tetralin content surpasses 50% in the mixed solvent, bagasse transformation rate remains on 86~87%, is all higher than using water alone as solvent liquefaction (67%) and tetralin as solvent liquefaction (84%) while the bio-oil yield was maintained at 24 to 34%, and when the tetrahydronaphthalene content was 50%, the bio-...

Embodiment 3

[0039] (1) raw material preparation: with embodiment 1.

[0040] (2) Liquefaction experiment

[0041] Weigh 30g of dry bagasse and NaOH with an amount of 0.1-4.0% of the amount of bagasse. NaOH is first made into an alkali solution with 120 grams of water, then pour the bagasse and alkali solution into a polyethylene sealed bag and mix well, and seal the mouth of the bag , placed at room temperature for 23 hours. Add the bagasse after alkaline immersion into the reaction kettle together with the lye and 120 grams of water. After evacuating the air in the kettle with hydrogen for 3 times, raise the temperature to the predetermined reaction temperature of 300℃ at a heating rate of 5℃ / min, and stir at 300rpm Liquefied at a constant temperature for 1 hour under the conditions, and the steps after the reaction were the same as in Example 1. As the amount of NaOH increased from 0.1% to 4.0%, the conversion increased from 70.4% to 98.9%; the yield of bio-oil increased from 20% to 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com