Closed cycle mixed refrigerant systems

a technology of closed cycle and mixed refrigerant, applied in refrigeration machines, lighting and heating apparatus, solidification, etc., can solve the problems of affecting the power consumption of natural gas liquefaction, and achieve the effect of improving liquefaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

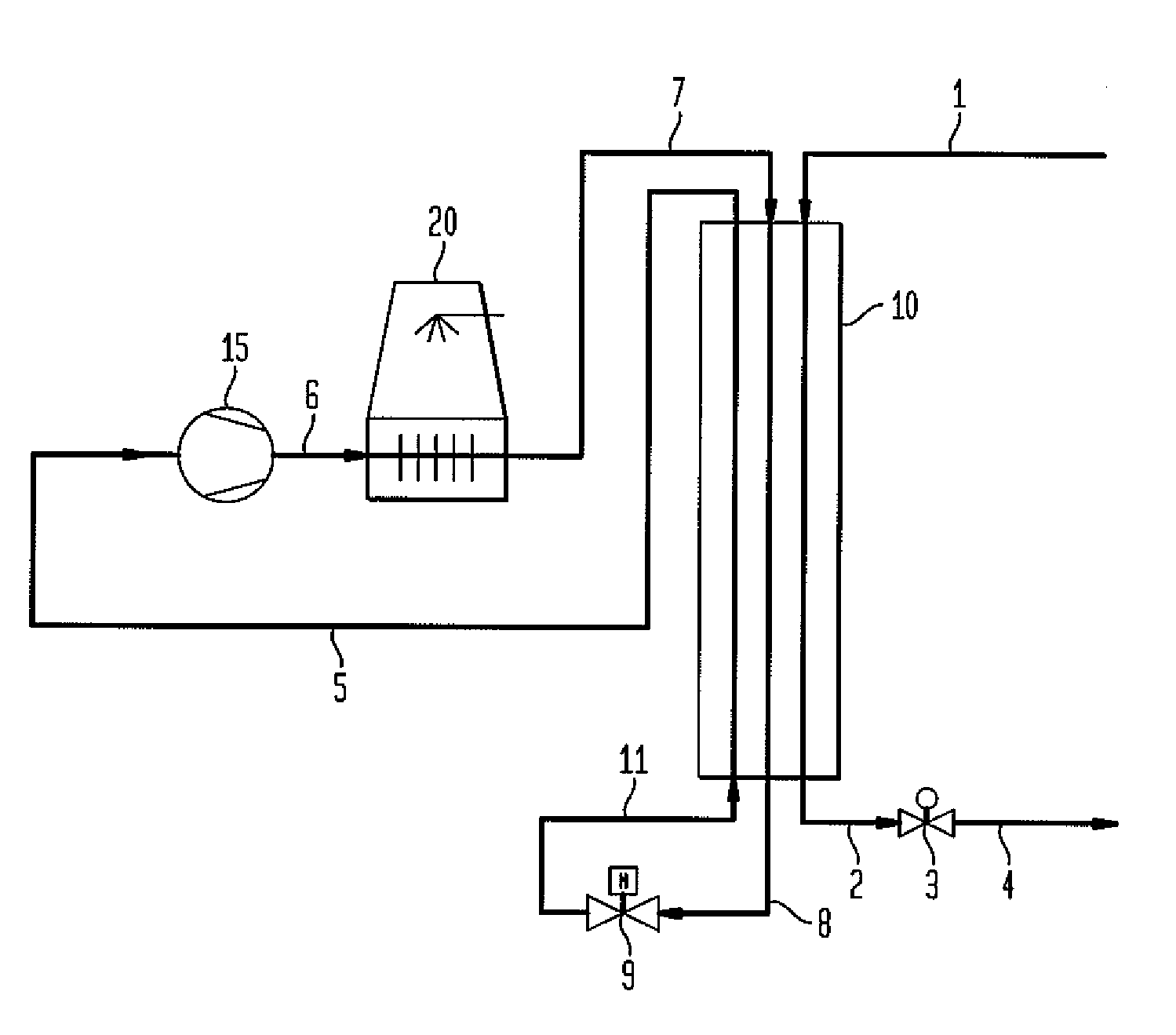

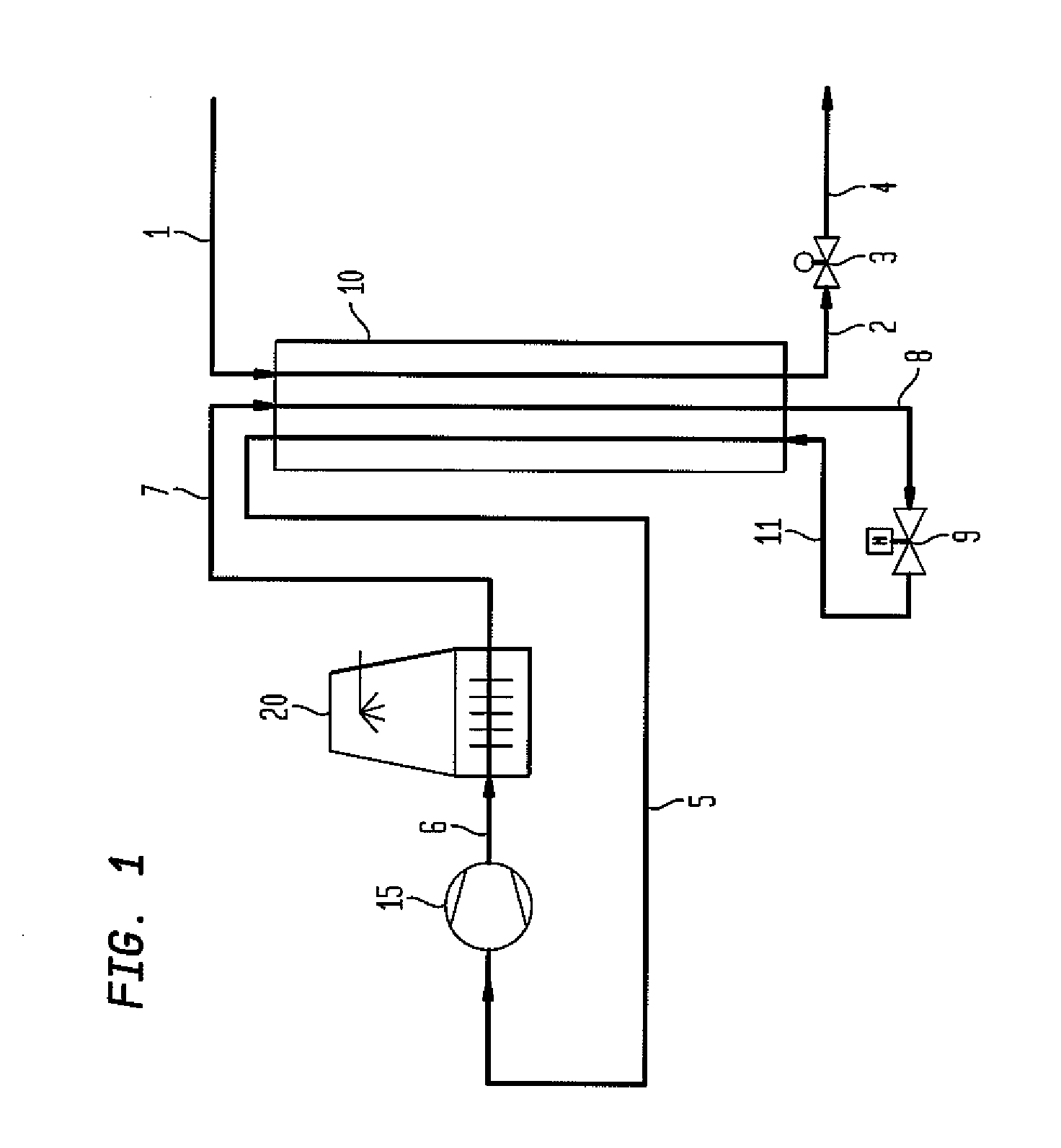

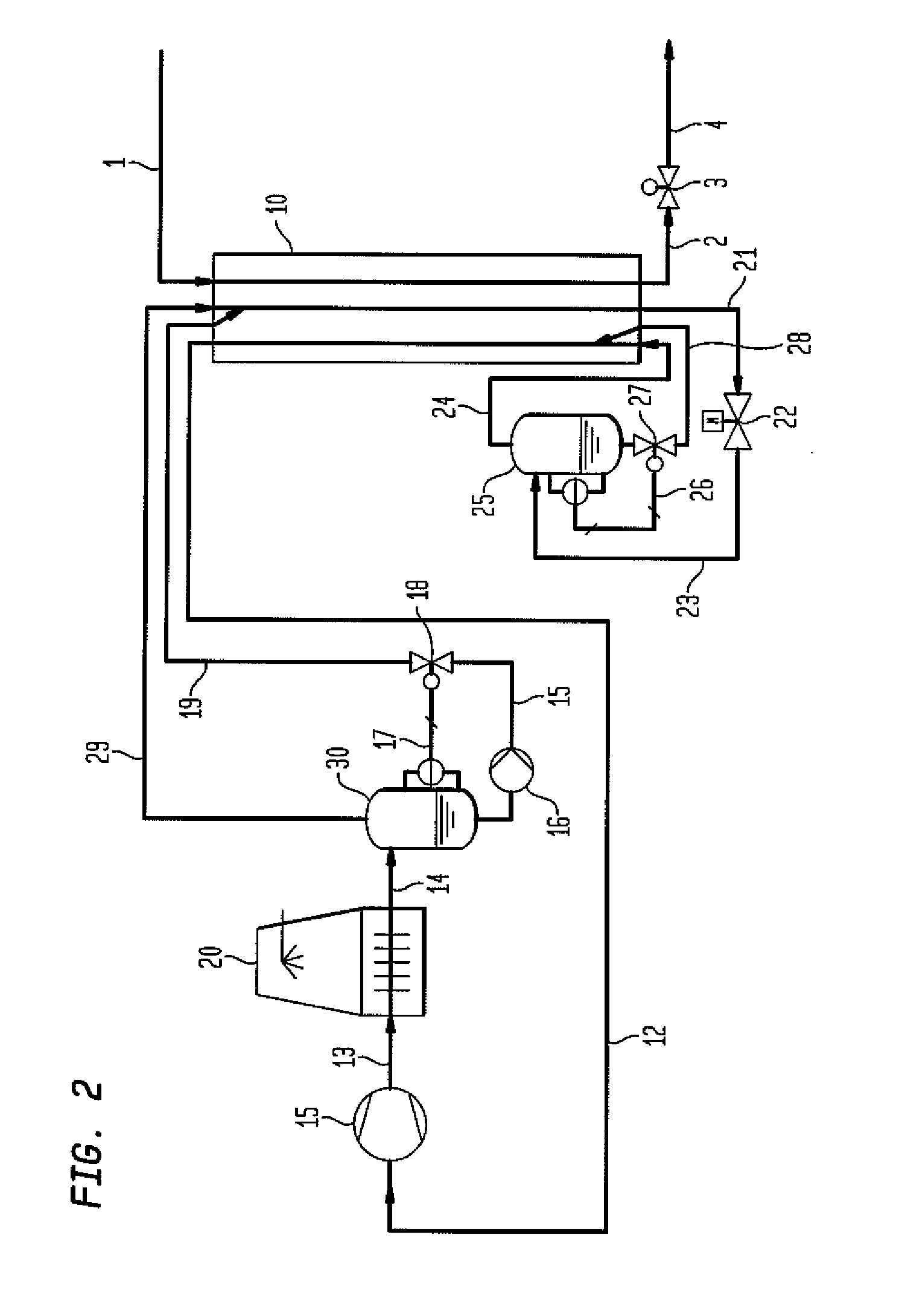

[0041]FIG. 2 shows a mixed refrigerant system employing the methods of the present invention. In this system, both warm 30 and cold end 35 phase separators are present. There are different refrigerant compositions in each of the phase separators and at the bottom of the main heat exchanger upstream of the Joule-Thompson valve.

[0042]For purposes of FIGS. 2, 3, 4 and 5, common components compressor, evaporative cooler, main heat exchanger, natural gas feed and liquefied product recovery have been designated with the same numbers throughout.

[0043]By changing the relative liquid holdup in the separators and the heat exchanger backup, the refrigerant composition in the loop can be adjusted. The liquid level in the warm end separator is continuously controlled online in order to regulate the iso-pentane in the five-component refrigerant mixture depending on various input conditions. If a higher level of warm end heat transfer is required in the main heat exchanger, a higher amount of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com