Double-tube vacuum film sperm separation method and separation device

A separation device and vacuum film technology, applied in the field of cell biology, can solve the problems affecting semen separation and processing, low recovery rate, etc., and achieve the effects of improving sperm yield, high recovery rate and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

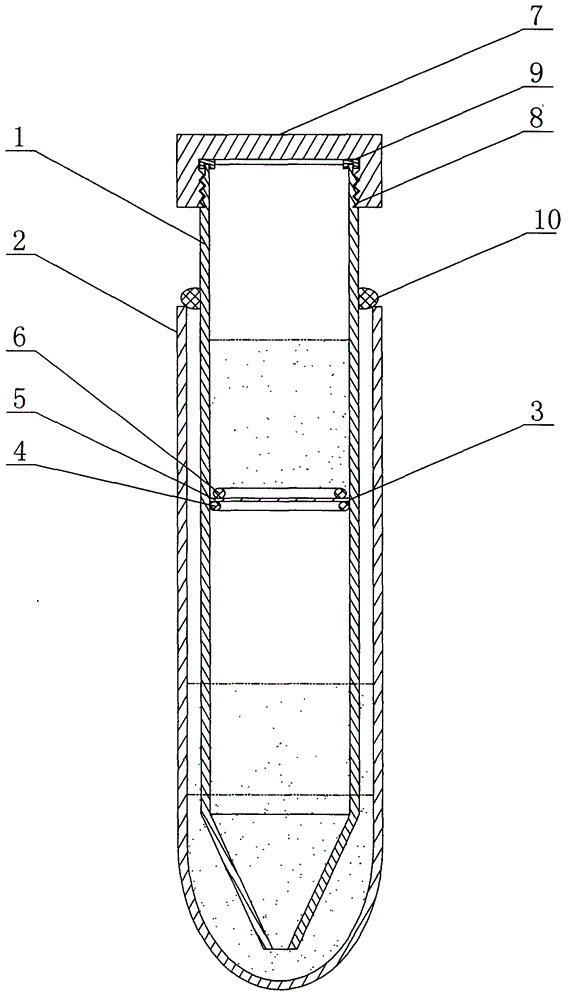

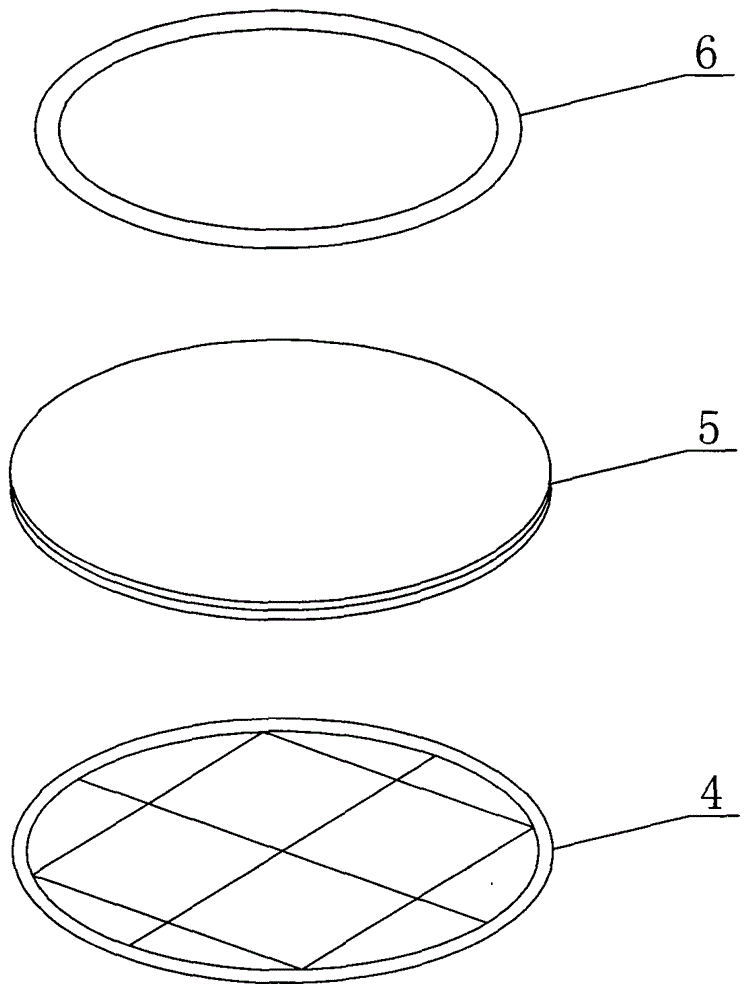

[0039]Embodiment 1: A sperm separation device according to the present invention, the main structure includes a centrifuge inner tube 1 and a centrifuge tube 2 . The centrifuge tube 2 adopts a centrifuge tube 2 with a specification of 15ml, and the centrifuge inner tube 1 is placed in the centrifuge tube 2 . The middle and upper part of the centrifuge inner tube 1 is a cylindrical structure with a tube wall thickness of 0.5 mm, an outer diameter of 13 mm and a length of 95 mm. It can be matched with the centrifuge tube 2 of 15ml specification. The lower part of the centrifuge inner tube 1 is a conical structure with an opening at the tip, so that the separated sperm clusters can be concentrated in the center of the bottom of the centrifuge inner tube 1, and the separated sperm clusters can be separated from the centrifugal tube 1 and the centrifuge tube 2. Leave the bottom of the centrifuge tube 2 through the opening. And the bottom diameter of the lower cone is 13mm, the ti...

Embodiment 2

[0050] Embodiment 2: A sperm separation device according to the present invention, the main structure includes a centrifuge inner tube 1 and a centrifuge tube 2 . The centrifuge tube 2 adopts a centrifuge tube 2 with a specification of 10ml, and the centrifuge inner tube 1 is placed in the centrifuge tube 2 . The middle and upper part of the centrifuge inner tube 1 is a cylindrical structure with an upper diameter and a lower diameter, and its outer diameter is 13 mm, upper end inner diameter is 12 mm, lower end inner diameter is 11 mm, and length is 100 mm. It can be matched with the centrifuge tube 2 of 10ml specification. The lower part of the centrifuge inner tube 1 is a conical structure with an open tip, so that the separated sperm clusters can be concentrated in the center of the bottom of the centrifuge inner tube 1, and the separated sperm clusters are separated from the centrifuge tube 1 and the centrifuge tube 2. It can stay at the bottom of the centrifuge tube 2 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com