Preparation method for lead zinc niobate-lead titanate monocrystal

A technology of lead niobate zincate and lead titanate, which is applied in the growth field of single crystal materials, can solve the problems of environmental hazards, PbO is volatile, and has not been applied to PZN-PT single crystals, etc., and achieves accelerated growth speed and crystal integrity Good, the effect of shortening the crystal growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

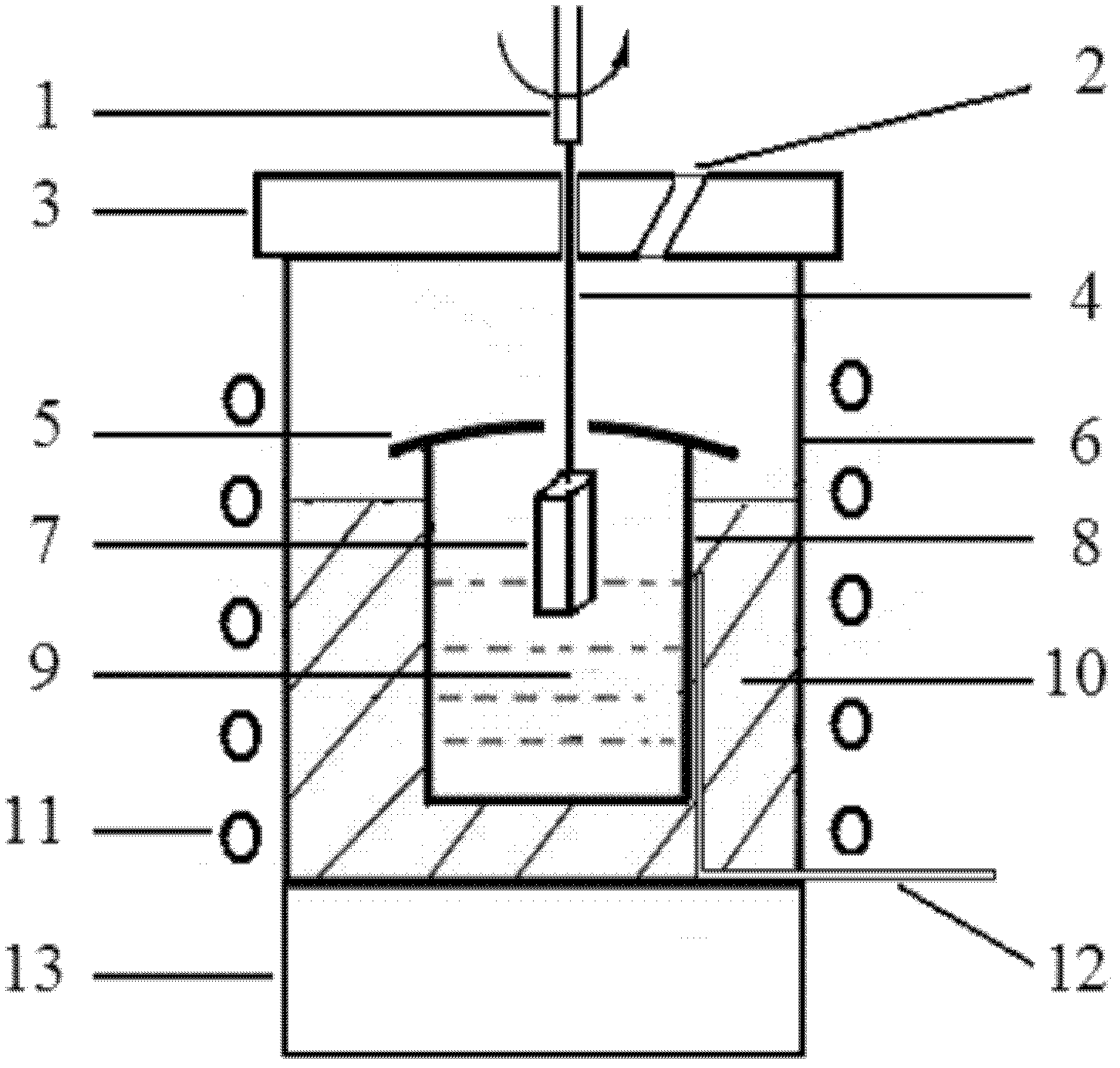

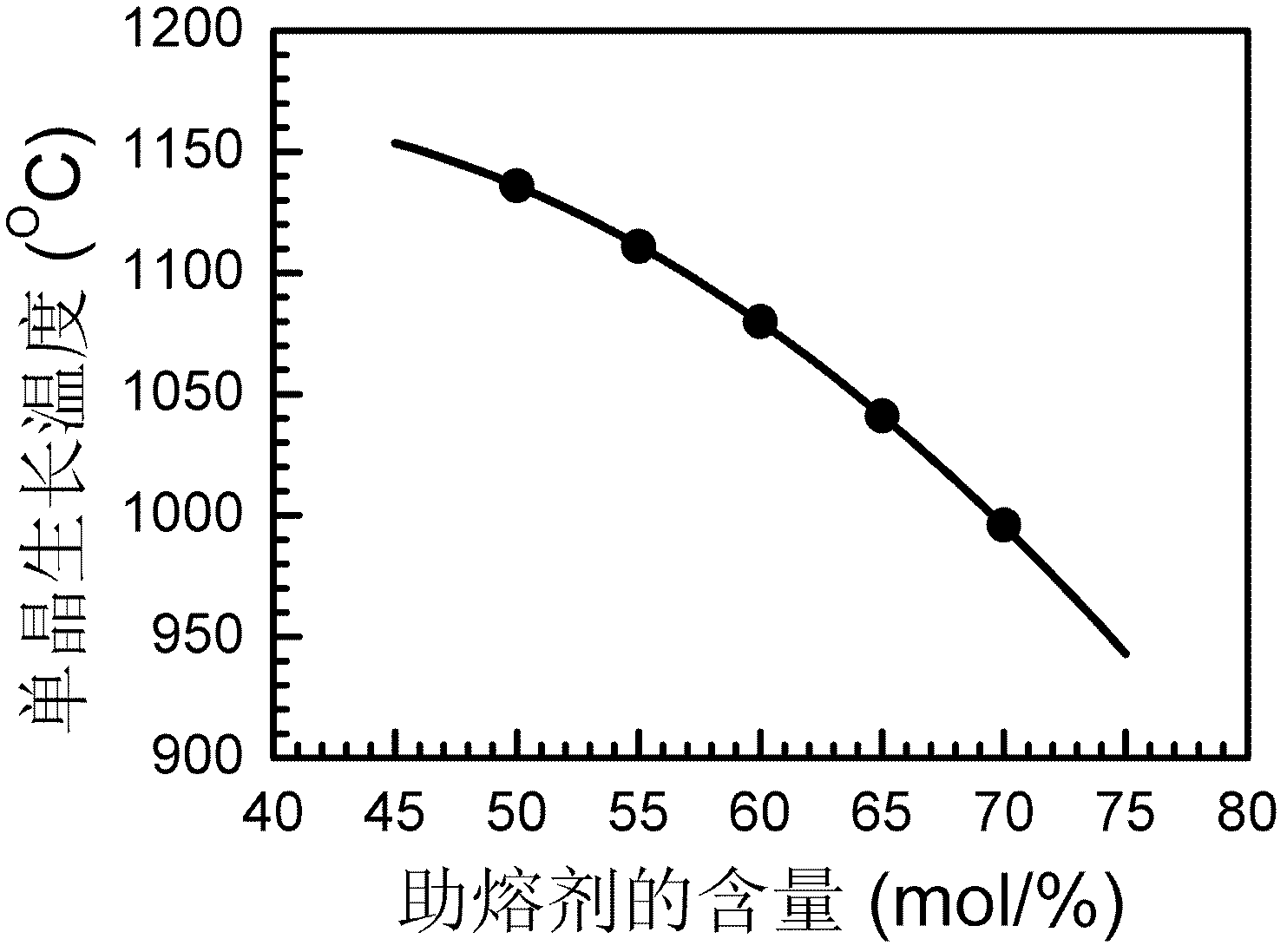

Method used

Image

Examples

Embodiment 1

[0033] Example 1 0.91Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.09PbTiO 3 Single crystal preparation

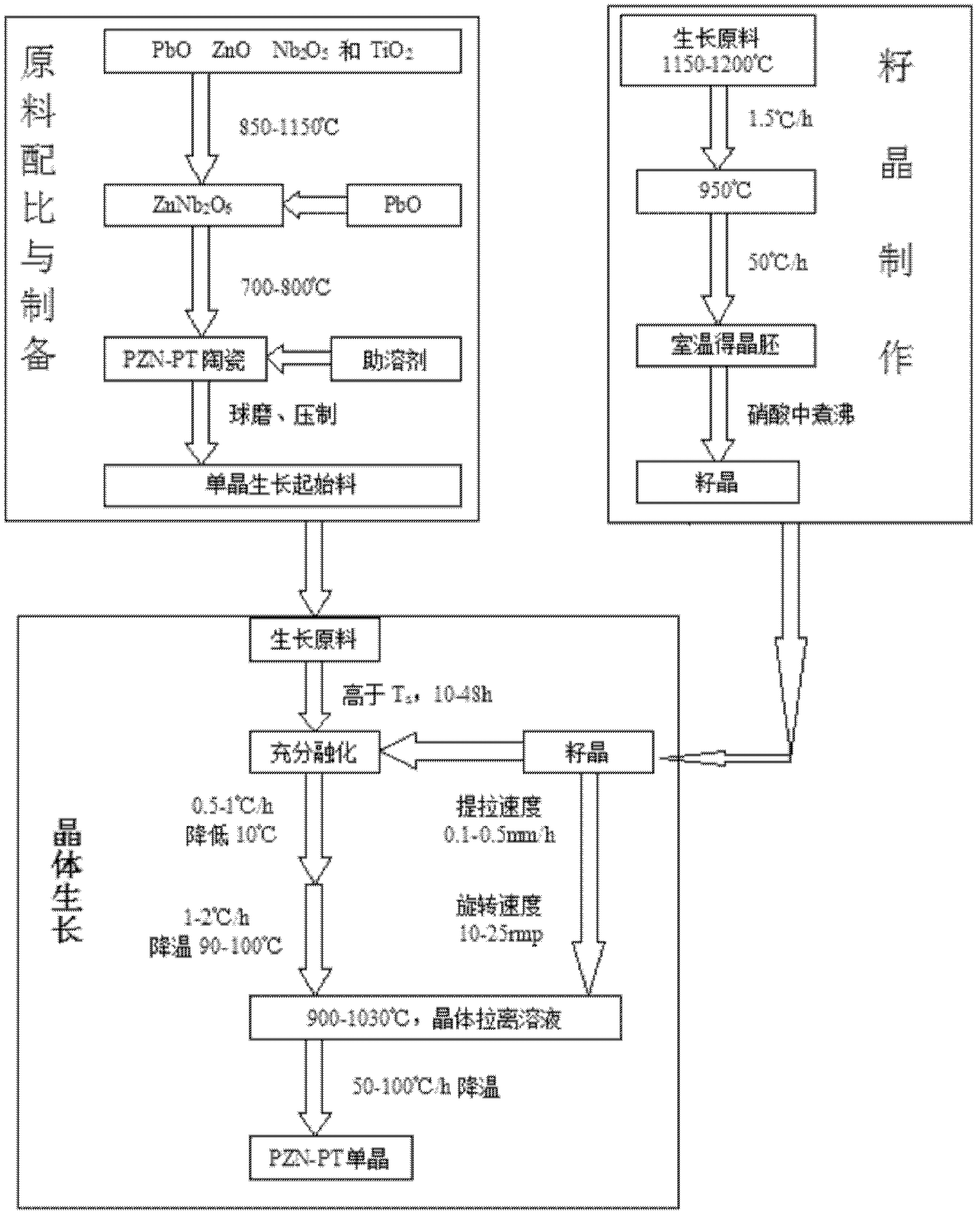

[0034] Using high-purity PbO, ZnO, Nb 2 o 5 and TiO 2 As an initial raw material, the following processes are included:

[0035] 1. Raw material processing

[0036] (1), the ZnO, Nb 2 o 5 , TiO 2 Mix materials according to stoichiometric ratio, ball mill for 4 hours and pre-sinter at 850°C for about 4 hours to obtain ZnNb 2 o 6 and a small amount of zinc niobium titanium oxide;

[0037] (2) Add PbO according to the stoichiometric ratio, heat to 700°C after ball milling and hold for 3 hours to obtain 0.91PZN-0.09PT ceramic powder;

[0038] (3) According to the metering relationship of the molar ratio of PZN-PT ceramic powder to flux = 3:7, add flux to the 0.91PZN-0.09PT ceramic obtained in step (2), and the flux is pure PbO. The flux and the solute are ball milled and mixed, and pressed into blocks to obtain the starting material for single crystal growth, which is put into the pl...

Embodiment 2

[0047] Example 2 0.88Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.12PbTiO 3 Single crystal preparation

[0048] Select high-purity chemical reagents PbO, ZnO, Nb 2 o 5 and TiO 2 Grow as starting material.

[0049] 1. Raw material processing

[0050] (1), the raw materials ZnO, Nb 2 o 5 , TiO 2 Mix materials according to stoichiometric ratio, ball mill for 8 hours and pre-sinter at 1150°C for 1 hour to obtain ZnNb 2 o 6 and a small amount of zinc niobium titanium oxide;

[0051] (2) Add PbO according to the stoichiometric ratio, heat to 800°C after ball milling and hold for 1 hour to obtain 0.88PZN-0.12PT ceramics;

[0052] (3) According to the metering relationship of the molar ratio of PZN-PT ceramic powder to flux = 5:5, add flux to the PZN ceramic powder obtained in step (2). Fluxes are PbO and B 2 o 3 mixture of PbO and B 2 o 3The mol ratio=48:2. The flux and the solute are mixed by ball milling and pressed into blocks to obtain the starting material for single crystal grow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com