Gasification process and preparation method of heavy metal ion adsorbent for gasification process

An adsorbent, heavy metal technology, applied in gasification process, chemical instruments and methods, fixed bed gasification and other directions, can solve the problems of increasing investment cost, reducing output, reducing feed amount, etc., to reduce the consumption of water resources, Low water vapor content, reducing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a heavy metal adsorbent for a gasification process, the raw material of the adsorbent is a single or mixed oil shale pyrolysis residue,

[0029] The method comprises the steps of:

[0030] (1) Recovery of oil shale pyrolysis residue: The oil shale pyrolysis residue used in this example is the pyrolysis residue of Fushun oil shale obtained by dry distillation at 500° C. for 30 minutes under nitrogen gas.

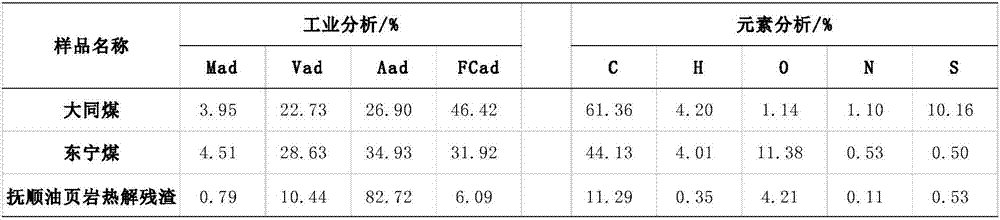

[0031] (2) Characterization of the test coal and the collected oil shale pyrolysis residue: the coal tested in this example is a typical steam coal, namely Shanxi Datong coal and Dongning coal. The industrial components of coal and oil shale pyrolysis residues were determined by the industrial analysis method of GB / T212-2008 coal, and the elemental analysis results of coal and oil shale pyrolysis residues were obtained by the elemental analysis method of GB / T31391-2015 coal. The analysis results are shown in Table 1:

[0032]

[0033] Table...

Embodiment 2

[0040] In this embodiment, on the basis of the foregoing embodiments, the characteristics of coal and oil shale pyrolysis residues have a great influence on the entire process. In order to better understand the physical and chemical properties of the raw materials, in the step (2), the Coal and oil shale pyrolysis residues were detected by field scanning electron microscope / energy dispersive X-ray spectrometer (SEM / EDX), X-ray diffraction spectrum (XRD), specific surface aperture tester (BET) and ash melting characteristics.

[0041] The XRD analysis results show that the content of kaolin in Fushun oil shale pyrolysis residue is relatively high, and the main reaction mechanism for its absorption of Cd is Al 2 o 3 2SiO2 2 +CdCl 2 +H 2 O=CdO·Al 2 o 3 2SiO2 2 +2HCl↑.

Embodiment 3

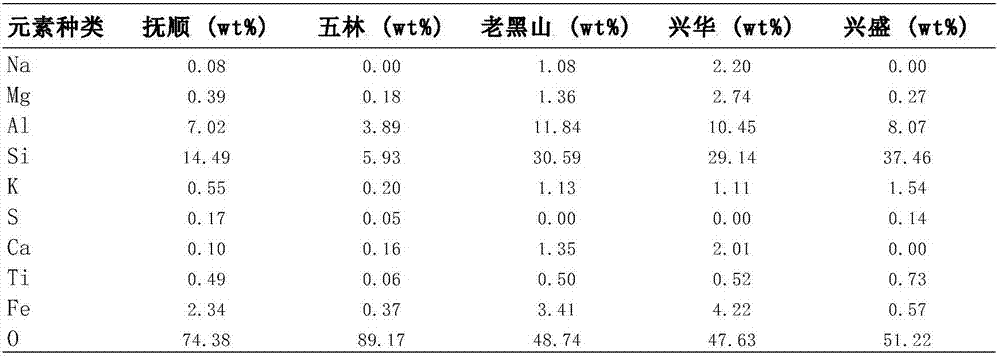

[0043] In this example, on the basis of the above examples, six kinds of oil shale pyrolysis residues were recovered for testing, namely Fushun oil shale, Wulin oil shale, Laoheishan oil shale, Xingsheng oil shale and Xinghua oil shale. Table 3 shows the elemental composition of oil shale determined by energy spectrum analyzer EDS:

[0044]

[0045] table 3

[0046] Table 4 shows the results of industrial analysis and elemental analysis of oil shale:

[0047]

[0048] Table 4

[0049] The composition and content of clay minerals in oil shale pyrolysis residues can be quickly identified through the method of the present invention, and the most suitable oil shale pyrolysis residues can be selected or mixed with various oil shales in a certain proportion according to the different types of heavy metals in coal The pyrolysis residue is used as an adsorbent to achieve the optimal purification effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com