Preparation method and applications of CuS catalyst having three-dimensional layered structure

A layered structure and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor cycle stability and difficult recycling of CuS catalysts, and achieve the benefit of large-scale The effect of promotion, convenient and fast separation and treatment, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

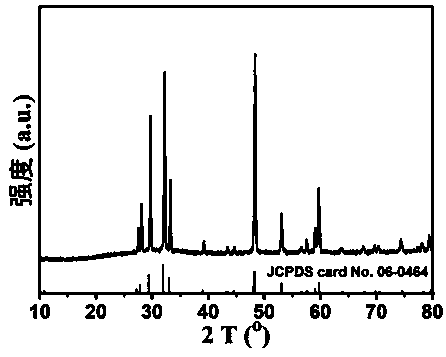

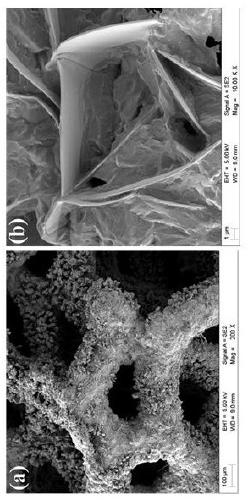

[0043] Mix the foamed copper and sulfur powder at a molar ratio of 1:4 and seal the container, place it in a tube furnace, heat up to 400 ℃ at a rate of 5 ℃ / min under the protection of a nitrogen atmosphere and keep it for 5 hours, then The temperature is lowered to room temperature at a cooling rate of 10°C / min, and the obtained sample is washed with water and ethanol, and dried to obtain the final product. The obtained CuS catalyst was subjected to X-ray diffraction (XRD) and scanning electron microscopy, and the results are shown respectively figure 1 with figure 2 . by figure 1 It can be seen that all the diffraction peaks are consistent with the standard pattern of CuS, indicating that the crystalline phase of the material is a pure CuS phase. by figure 2 It can be seen that the catalyst prepared according to the method provided by the present invention is a CuS catalyst with a three-dimensional network layered structure composed of nanosheets.

Embodiment 2

[0045] Mix the foamed copper and sulfur powder at a molar ratio of 1:4 and seal the container. Place it in a tube furnace. Under the protection of a nitrogen atmosphere, it will be heated to 500 ℃ at a rate of 5 ℃ / min and kept for 5 hours. The temperature is lowered to room temperature at a cooling rate of 10°C / min, and the obtained sample is washed with water and ethanol, and dried to obtain the final product. Scan the obtained catalyst by electron microscope, the result is image 3 ,by image 3 It can be seen that the catalyst prepared according to the method provided by the present invention has a three-dimensional network structure composed of nano-carpets.

Embodiment 3

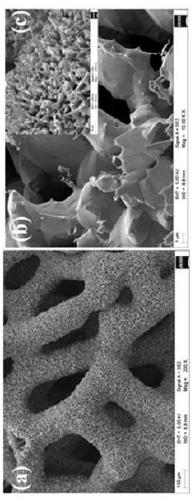

[0047] Mix the foamed copper and sulfur powder at a molar ratio of 1:4 and seal the container, place it in a tube furnace, heat it up to 600 ℃ at a rate of 5 ℃ / min under the protection of a nitrogen atmosphere and keep it for 5 hours, then The temperature is lowered to room temperature at a cooling rate of 10°C / min, and the obtained sample is washed with water and ethanol, and dried to obtain the final product. Scan the obtained catalyst by electron microscope, the result is Figure 4 ,by Figure 4 It can be seen that the catalyst prepared according to the method provided by the present invention has a three-dimensional network structure composed of a honeycomb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com