Liquefaction process and liquefaction equipment of glucose syrup

A technology of glucose syrup and process, applied in the directions of biochemical equipment and methods, biochemical instruments, sterilization methods, etc., can solve the problems of reduced product extraction rate, loss of dissolved protein, waste water discharge, etc., and achieve high product extraction rate and recovery. High rate, the effect of eliminating the phenomenon of boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

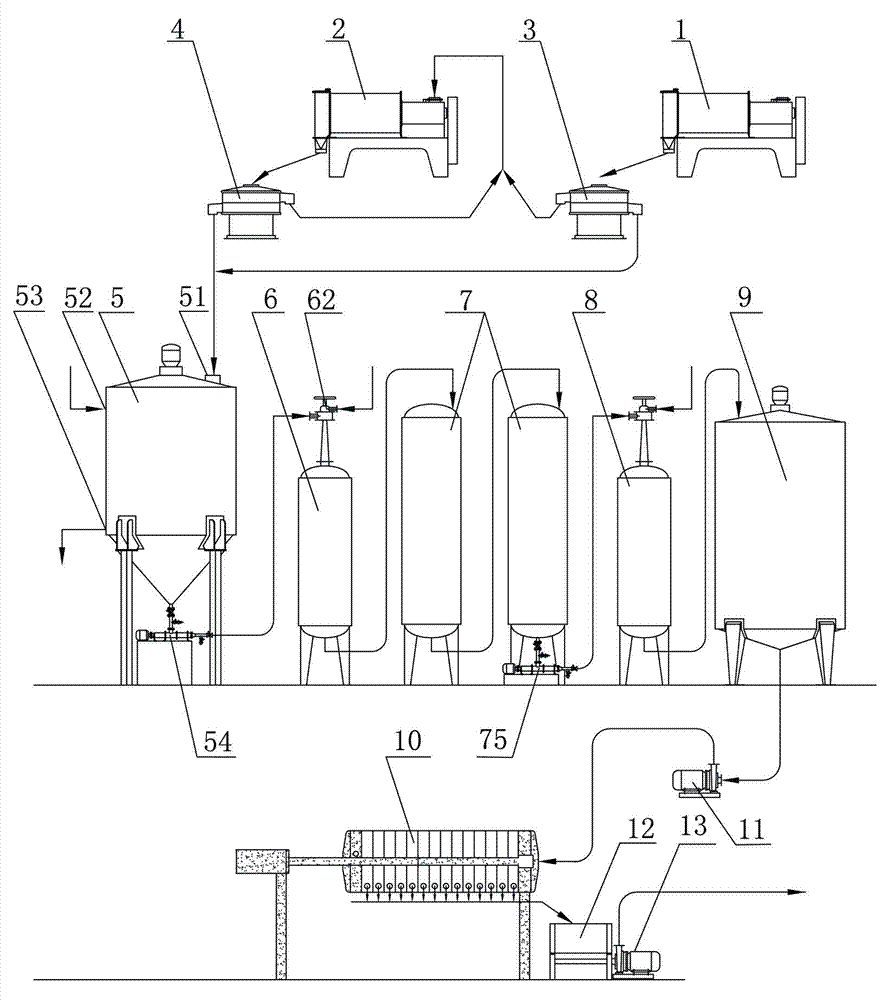

[0032] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0033] The implementation of the present invention provides a kind of liquefaction technique of glucose syrup, and this technique comprises the following steps:

[0034] Milling: Grinding raw grain dry material into fine grain powder with a particle size of 60 mesh to 80 mesh;

[0035] Slurry mixing: use warm water to adjust the fine grain powder into a primary slurry with a mass fraction of 28% to 32%, then keep the temperature and stir for 2 to 3 hours; then, add liquefied enzyme preparation and protein coagulant while stirring to form Secondary slurry;

[0036] Gelatinization: using an injector to spray and mix the secondary slurry and water vapor at a temperature not lower than 105°C in the injector, so that the secondary slurry is gelatinized and liquefied to form a coarse starch gelatinization liquid; and Constant temperature at a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com