Coking wastewater treatment method

A treatment method and technology of coking wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as unstable effluent indicators, easy inhibition or poisoning of microorganisms, etc. Achieve the effect of reducing organic load and toxicity inhibition, compact structure and reasonable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

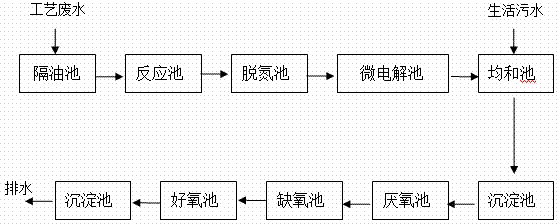

[0036] The process wastewater produced by a coking plant is mainly ammonia distillation wastewater and domestic sewage, and the water quality of ammonia distillation wastewater is shown in Table 1. Adopt processing method of the present invention to process, operate as follows:

[0037] The process wastewater enters the grease trap to remove heavy oil and then enters the air flotation degreasing machine. After the oil droplets and microbubbles in the wastewater adsorb each other to form an oil slick, the oil layer is discharged through the scraper coating machine, and the lower layer of wastewater is discharged through the bottom pipeline into the denitrification tank; adding Na 2 CO 3 Adjust wastewater pH to 9, according to Mg 2+ :PO 4 3- :NH 4 + =1.2:1:1 (molar ratio) by adding MgCl 2 and K 2 HPO 4 , forming MgNH 4 PO 4 .6H 2 O precipitation makes NH in wastewater 4 + can be removed; after denitrification, the wastewater enters the reaction pool, according to Fe...

Embodiment 2

[0040] The process wastewater produced by a coking plant is mainly ammonia distillation wastewater and domestic sewage. The water quality of ammonia distillation wastewater is shown in Table 2. Adopt processing method of the present invention to process, operate as follows:

[0041] The process wastewater enters the grease trap to remove heavy oil and then enters the air flotation degreasing machine. After the oil droplets and microbubbles in the wastewater adsorb each other to form an oil slick, the oil layer is discharged through the scraper coating machine, and the lower layer of wastewater is discharged through the bottom pipeline into the denitrification tank; adding Na 2 CO 3 Adjust wastewater pH to 9, according to Mg 2+ :PO 4 3- :NH 4 + =1.5:1:1 (molar ratio) by adding MgCl 2 and K 2 HPO 4 , forming MgNH 4 PO 4 .6H 2 O precipitation makes NH in wastewater 4 + can be removed; after denitrification, the wastewater enters the reaction pool, according to Fe 2+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com