Method for processing heavy-metal complexed wastewater through Fenton reinforced iron-chip internal electrolysis process

An internal electrolysis and heavy metal technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., to reduce organic load and treatment difficulty, reduce consumption, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

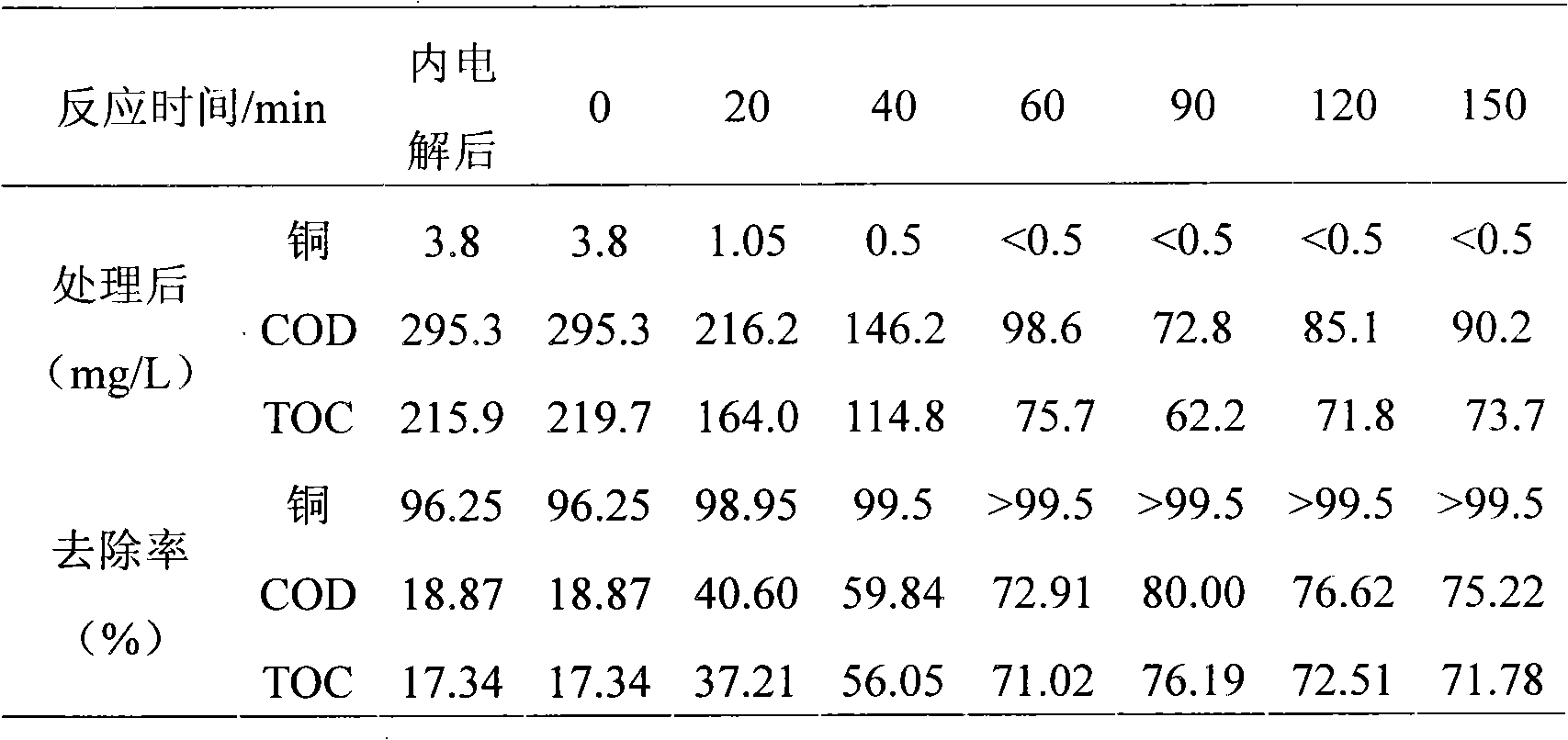

[0017] Example 1: Treatment of EDTA-complexed copper wastewater by electrolytic fluidized bed in iron filings combined with Fenton oxidation

[0018] Soak cast iron chips with a particle size of 0.7mm in detergent and degrease them at 80°C for 20 minutes, then soak them in 1% hydrochloric acid for 0.5 minutes to remove surface oxides, rinse them with clean water, and dry them for later use. Then mix 20g of cast iron shavings after the above-mentioned activation pretreatment and 20g of activated carbon particles with a particle size of 1.2mm and add them into the fluidized bed reactor, then adjust the pH of the wastewater to 1.5 and then pass it into the fluidized bed. Dosing 0.06mol / LNa 2 SO 4 The solution is used as the electrolyte, the mechanical stirring speed is 80r / min, the flow rate of the waste water is controlled so that the residence time of the hydraulic power in the inner electrolysis reactor is 20min; then the inner electrolysis water is passed into the Fenton rea...

Embodiment 2

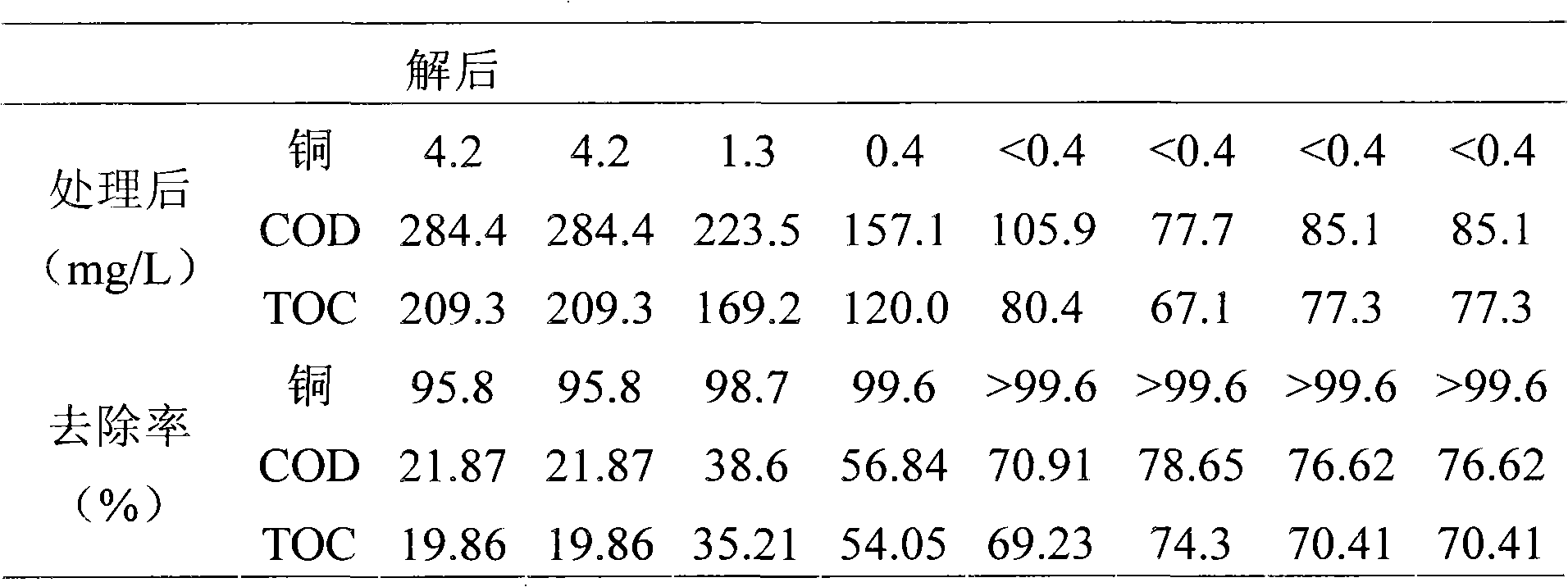

[0023] Example 2: Treatment of EDTA-complexed copper wastewater by internal electrolysis fixed bed combined with Fenton oxidation method

[0024] Soak the wire-like iron shavings in sodium hydroxide with a mass concentration of 9% and degrease at 100°C for 0.5h, then soak in hydrochloric acid with a volume fraction of 2% for 0.5h to remove surface oxides, rinse with clean water and dry spare. 80 g of filiform iron shavings and 20 g of activated carbon with a particle size of 4.5 mm are packed into the electrolytic fixed bed in iron filings after the above-mentioned activation pretreatment. Adjust the pH of the wastewater to 3.5 and pass it into the fixed-bed reactor, adopt the pulse water inlet method and intermittent aeration method, control the flow rate of the inlet water to maintain the hydraulic retention time of the wastewater at 60min, and pass the fixed-bed effluent into the Fenton reactor to measure The concentration of ferrous ions in the water is 330mg / L, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com