High concentration organic nitrogen waste water processing technology

A high-concentration organic nitrogen technology, applied in the field of high-concentration organic nitrogen wastewater treatment process, can solve the problems of poor stability, low treatment efficiency, and high cost, and achieve the effects of reducing impact, increasing denitrification rate, and reducing organic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

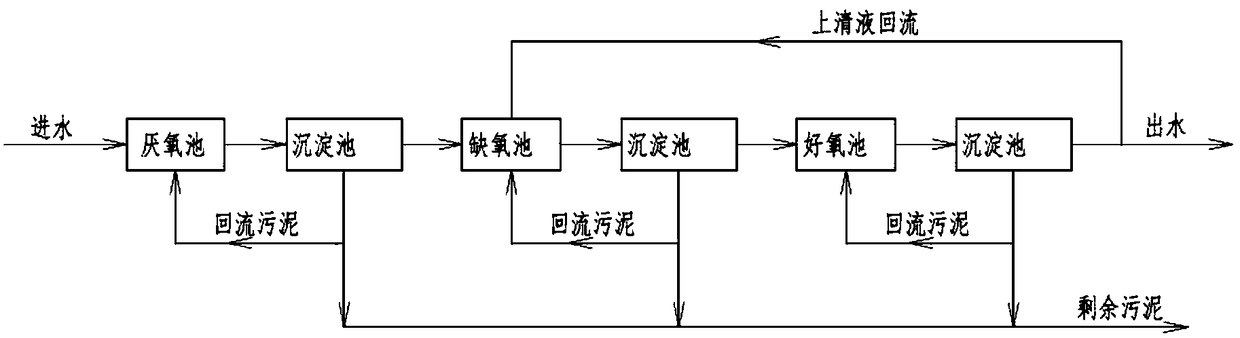

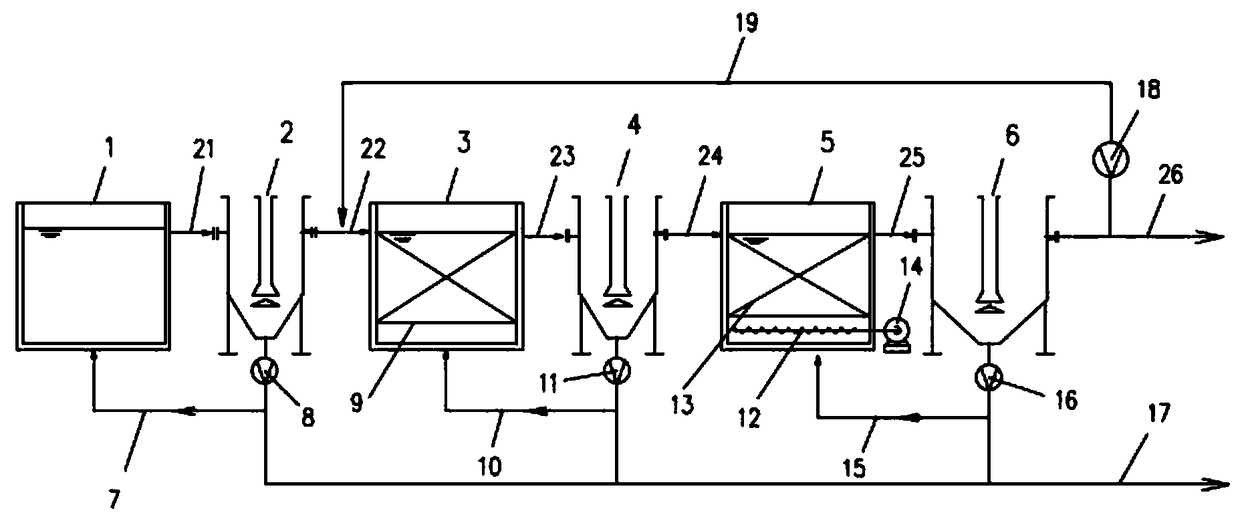

[0036]Pass the spandex production wastewater (COD is 3000mg / L, NH3-N is 60mg / L, TN is 250mg / L) into the anaerobic tank, the pH is 8, and the residence time is 30h. Through anaerobic biological treatment, COD is degraded at the same time The organic nitrogen is converted into ammonia nitrogen, the COD of the anaerobic effluent is reduced to about 200mg / L, and 97% of the effluent TN is ammonia nitrogen; the effluent from the anaerobic pool enters the anoxic pool and the aerobic pool for synergistic nitrification and denitrification , the total residence time of the anoxic pool and the aerobic pool is 25h, the dissolved oxygen concentration in the aerobic pool is 4mg / L, and then the supernatant of the nitrification reaction in the aerobic pool is returned to the anoxic pool, which can be used for denitrification The carbon source can reduce the COD load of the subsequent nitrification reaction, and can also use the nitrate nitrogen produced by the nitrification reaction; the DO in...

Embodiment 2

[0038] Pass the spandex production wastewater (COD is 5000mg / L, NH3-N is 35mg / L, TN is 500mg / L) into the anaerobic tank, the pH is 6, and the residence time is 20h. Through anaerobic biological treatment, while degrading COD The organic nitrogen is converted into ammonia nitrogen, the COD of the anaerobic effluent is reduced to about 300mg / L, and 95% of the effluent TN is ammonia nitrogen; the effluent from the anaerobic pool enters the anoxic pool and the aerobic pool for synergistic nitrification and denitrification , the total residence time of the anoxic pool and the aerobic pool is 30h, the dissolved oxygen concentration in the aerobic pool is 5mg / L, and then the supernatant of the nitrification reaction in the aerobic pool is returned to the anoxic pool, which can be used for denitrification The carbon source can reduce the COD load of the subsequent nitrification reaction, and can also use the nitrate nitrogen produced by the nitrification reaction; the DO in the aerobic...

Embodiment 3

[0040] Pass the spandex production wastewater (COD is 2500mg / L, NH3-N is 50mg / L, TN is 300mg / L) into the anaerobic tank, the pH is 9, the residence time is 25h, through anaerobic biological treatment, while degrading COD The organic nitrogen is converted into ammonia nitrogen, the COD of the anaerobic effluent is reduced to about 200mg / L, and 96% of the effluent TN is ammonia nitrogen; the effluent from the anaerobic pool enters the anoxic pool and the aerobic pool for synergistic nitrification and denitrification , the total residence time of the anoxic pool and the aerobic pool is 40h, the dissolved oxygen concentration in the aerobic pool is 3mg / L, and then the supernatant of the nitrification reaction in the aerobic pool is returned to the anoxic pool, this step can be used for denitrification The carbon source can reduce the COD load of the subsequent nitrification reaction, and can also use the nitrate nitrogen produced by the nitrification reaction; the DO in the aerobic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com