Machining wastewater treatment technology

A wastewater treatment and mechanical processing technology, applied in water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of complex water quality and inability to discharge directly, and achieve stable effluent quality, reduce Organic load and the effect of saving infrastructure costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and embodiments.

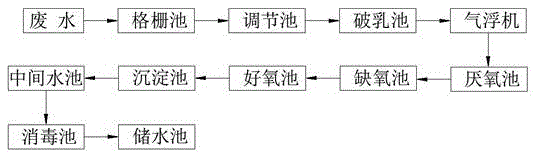

[0024] The mechanical processing wastewater treatment process of the present invention, the specific process steps are as follows:

[0025] (1) Pretreatment: The waste water enters the grid pool to intercept large particulate matter through the grid to avoid blockage caused by large particulate matter entering the sewage treatment system. Then it flows into the adjustment tank to balance the water quality and quantity, so that the waste water can enter the subsequent treatment unit evenly.

[0026] By adjusting the setting of the pool, the water quality and quantity can be fully balanced, so that the sewage can enter the subsequent treatment unit more evenly, improve the impact resistance of the whole system, and reduce the design scale of the treatment unit. Helps to reduce operating costs and the impact of water quality fluctuations. Considering the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com