Process for treatment of high density aquaculture sewage

A technology of aquaculture and process method, which is applied in the field of high-density aquaculture sewage treatment, can solve the problems of high investment and operation costs, and restrict the application and promotion of recirculating aquaculture mode, so as to reduce investment and operation costs, reduce organic load, The effect of easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

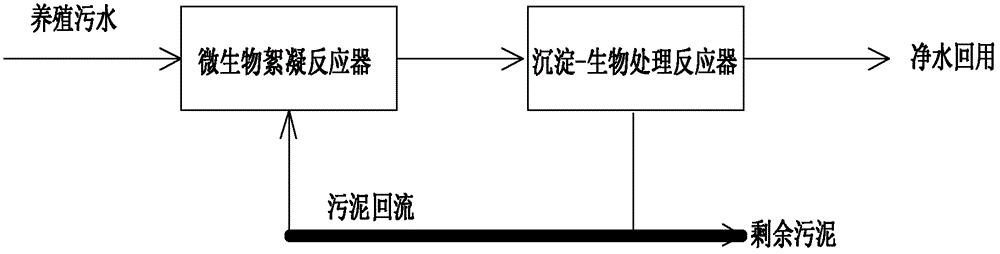

[0013] A process method for treating high-density aquaculture sewage, pumping high-density aquaculture sewage into the microbial flocculation reactor, adding activated and cultivated Bacillus subtilis seed bacterium liquid, the volume ratio of seed bacterium liquid to aquaculture sewage: 1 : 100; the bottom of the reactor is evenly equipped with an aeration device, the air-water ratio: 2: 1, dissolved oxygen: 2.2mg / L;

[0014] The high-density aquaculture sewage pumped into the microbial flocculation reactor is fully mixed with the suspended seed bacteria liquid put into it under the action of blast aeration to produce biological flocculants, decompose organic matter, and proliferate microorganisms. The mixing reaction time is 1 Hour;

[0015] The mixed liquid produced in the microbial flocculation reactor flows through the sedimentation-biological treatment reactor for solid-liquid separation and biochemical reaction;

[0016] The sedimentation-biological treatment reactor r...

Embodiment 2

[0020] A process method for treating high-density aquaculture sewage, pumping high-density aquaculture sewage into the microbial flocculation reactor, adding activated Bacillus subtilis seed bacteria liquid to it, the volume ratio of seed bacteria liquid to aquaculture sewage: 2 : 100; the bottom of the reactor is evenly equipped with an aeration device, the air-water ratio: 2.3: 1, dissolved oxygen: 2.5mg / L;

[0021] The high-density aquaculture sewage pumped into the microbial flocculation reactor is fully mixed with the suspended seed bacteria liquid put into it under the action of blast aeration to produce biological flocculants, decompose organic matter, and proliferate microorganisms. The mixing reaction time is 1.2 Hour;

[0022] The mixed liquid produced in the microbial flocculation reactor flows through the sedimentation-biological treatment reactor for solid-liquid separation and biochemical reaction;

[0023] The sedimentation-biological treatment reactor relies o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com