Efficient treatment combination process of acrylonitrile wastewater

A technology of acrylonitrile wastewater and combined process, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., and can solve the problem of lack of effluent in biochemical systems, insufficient understanding of wastewater characteristics, and denitrification of biochemical systems Insufficient functions and other problems, to achieve the effect of ensuring the denitrification effect, reducing the treatment load and treatment cost, and improving the treatment capacity and treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The influent of the catalytic oxidation tower of the combined process of efficient treatment of acrylonitrile wastewater is the wastewater produced by the four-effect evaporation and stripping of the sewage of the acrylonitrile plant. The water quality indicators are as follows: COD2081mg / L, NH 3 -N34.9mg / L, TN337mg / L, pH7.40, CN - 7.73mg / L, acrylonitrile (AN) 0.30mg / L, water temperature 65°C.

[0029] The water quality indicators of domestic sewage in the factory area are as follows: COD340mg / L, BOD 5 176mg / L, NH 3 -N23.4mg / L, SS167mg / L, pH7.16.

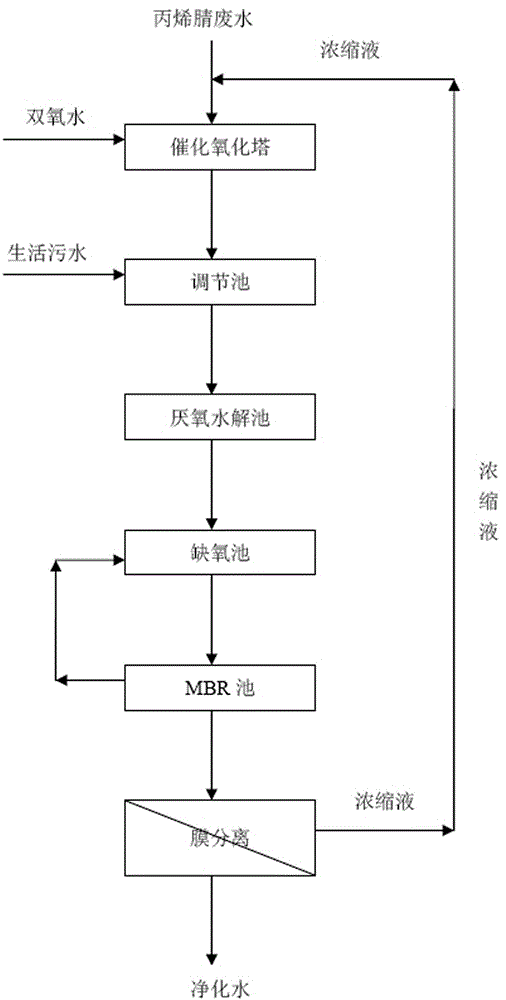

[0030] like figure 1As shown, the acrylonitrile production wastewater first enters the catalytic oxidation tower for catalytic hydrogen peroxide oxidation treatment. The catalyst is a supported catalyst, the carrier SBA-16 mesoporous molecular sieve, the active component is nano-CeO, and the catalytic oxidation tower adopts an upflow fixed bed form. , The hydraulic retention time is 60min. The effluent of the catalytic o...

Embodiment 2

[0033] The influent of the catalytic oxidation tower of the combined process of efficient treatment of acrylonitrile wastewater is the wastewater produced by the four-effect evaporation and stripping of the sewage of the acrylonitrile plant. The water quality indicators are as follows: COD2395mg / L, NH 3 -N45.3mg / L, TN306mg / L, pH7.36, CN - 7.60mg / L, acrylonitrile (AN) 0.30mg / L, water temperature 70°C.

[0034] The water quality indicators of domestic sewage in the factory area are as follows: COD319mg / L, BOD 5 160mg / L, NH 3 -N25.2mg / L, SS159mg / L, pH7.28.

[0035] like figure 1 As shown, the acrylonitrile production wastewater first enters the catalytic oxidation tower for catalytic hydrogen peroxide oxidation treatment, the catalyst is a supported catalyst, the carrier SBA-16 mesoporous molecular sieve, and the active component is MnO 2 , The catalytic oxidation tower adopts the fluidized bed form, and the hydraulic retention time is 45min. The effluent of the catalytic ox...

Embodiment 3

[0038] High-efficiency treatment of acrylonitrile wastewater combined process Catalytic oxidation tower feed water is wastewater produced by four-effect evaporation and stripping of acrylonitrile plant sewage, and its water quality indicators are as follows: COD2037mg / L, NH 3 -N46.8mg / L, TN325mg / L, pH7.33, CN-6.39mg / L, acrylonitrile (AN) 0.30mg / L, water temperature 67℃.

[0039] The water quality indicators of domestic sewage in the factory area are as follows: COD320mg / L, BOD 5 158mg / L, NH 3 -N26.1mg / L, SS142mg / L, pH7.29.

[0040] like figure 1 As shown, the acrylonitrile production wastewater first enters the catalytic oxidation tower for catalytic hydrogen peroxide oxidation treatment. The catalyst is a supported catalyst, the carrier MCM-41 mesoporous molecular sieve, the active component is Cu, and the catalytic oxidation tower adopts an upflow fixed bed form. The hydraulic retention time is 120min. The effluent of the catalytic oxidation tower and the domestic sewage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com