Process for efficient separation of organic carbon source in sewage and energy development and utilization

A technology for organic carbon and source separation, applied in biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of large chemical flocculation sludge production, difficult treatment and disposal, and high pollution problems such as sludge production reduction, significant environmental benefits, and organic load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

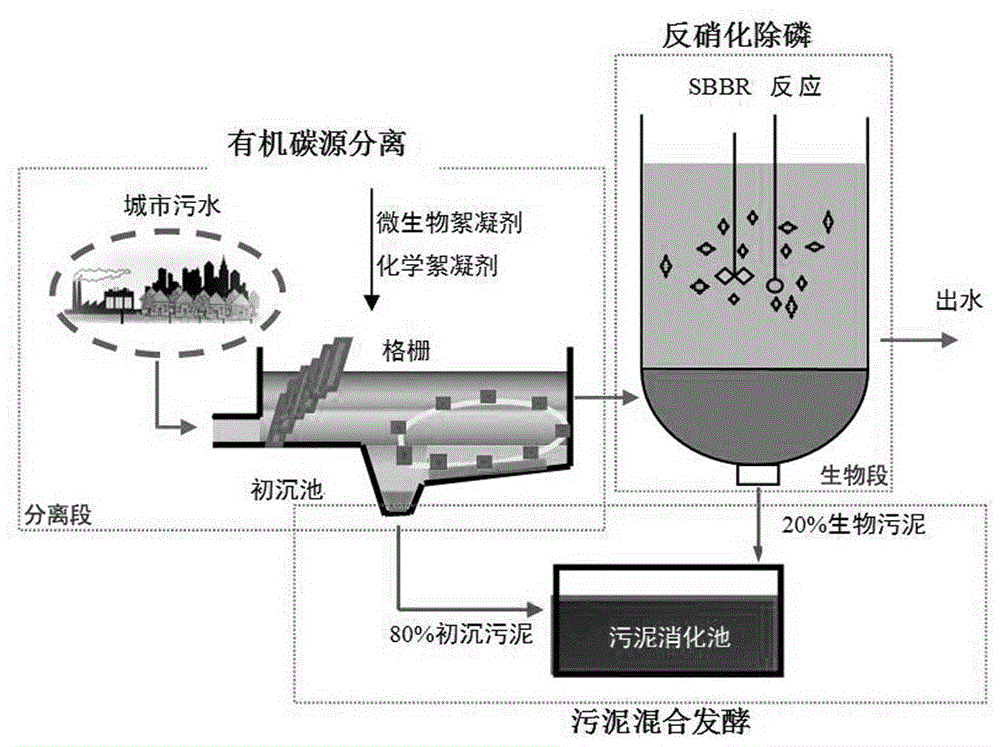

[0016] The invention provides a high-efficiency source separation and energy development and utilization process of organic carbon in sewage. Combine the following figure 1 The examples given illustrate the invention.

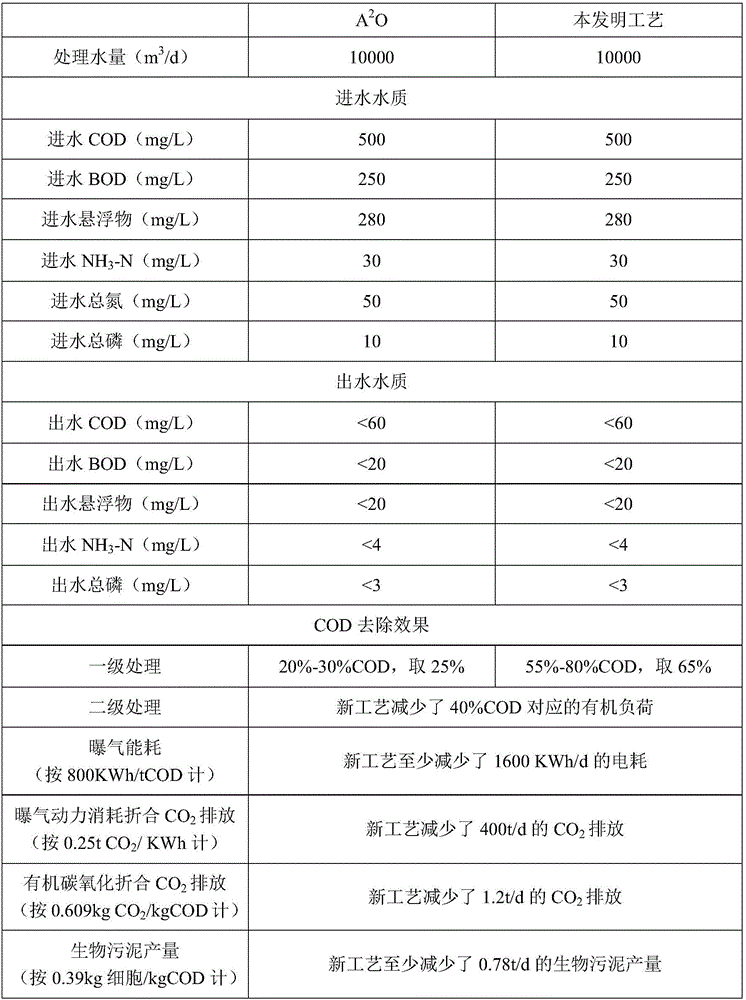

[0017] The influent is typical urban sewage, and the influent water volume is 10,000 tons / day. The urban sewage first enters the coarse and fine screens and the grit chamber, and then enters the primary sedimentation tank. In the 8mL / L (or 9mL / L, or 10mL / L) Paenibacillus colloid microbial flocculant and 0.1mg / L polyacrylamide Under the joint action, most of the suspended organic matter, colloid and part of the dissolved organic matter in the sewage are settled, the initial sedimentation time is 1.5 hours, the fast stirring is 2 minutes, and the slow stirring is 30 minutes; it is separated from the sewage in the form of primary sedimentation sludge. The effluent from the primary sedimentation tank enters the sequencing batch biofilm reactor (SBBR) in the biolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com