Integral pretreatment device for leachate in waste incineration power plant

A pretreatment device, waste incineration technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The back-end equipment has a short life cycle and high maintenance costs, and achieves the effects of efficient degradation of organic macromolecules, small footprint, and low land cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

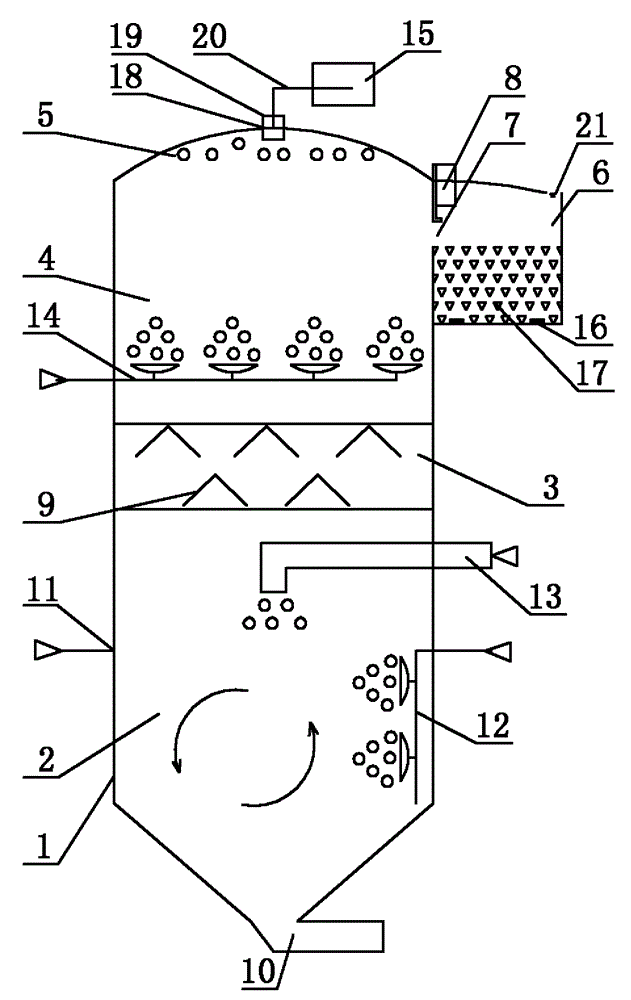

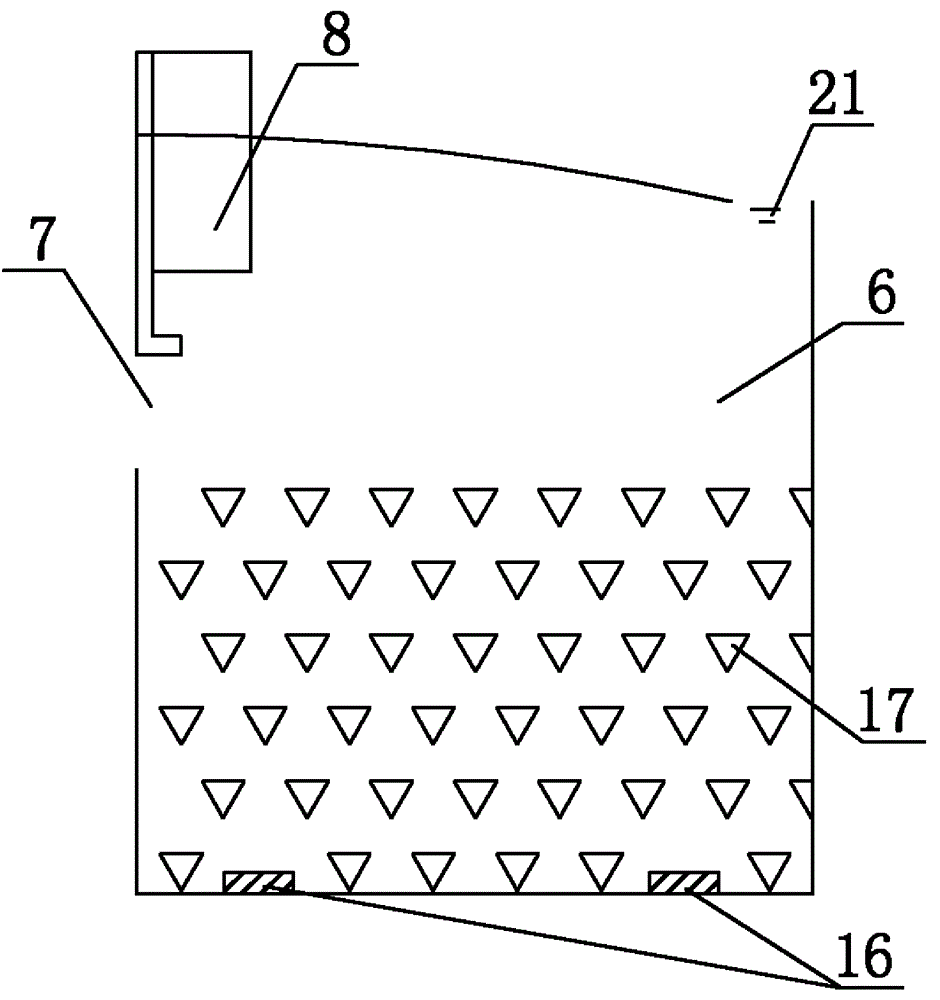

[0015] An integrated pretreatment device for leachate in a waste incineration power plant, see figure 1 , figure 2 : It includes a shell 1, which is arranged in a vertical structure. The inside of the shell 1 is respectively arranged with an aeration and dosing sediment removal area 2, a mud-water separation area 3, an ammonia nitrogen stripping area 4, and waste gas collection Zone 5, the top of one side of the housing 1 is provided with a mixing reaction chamber 6, and the side wall of the upper part of the housing 1 at the position of the ammonia nitrogen stripping zone 4 is provided with a water outlet 7, and the water outlet 7 is connected to the mixing reaction chamber 6 on the outside. The reaction chamber 6 is equipped with an electrolysis and micro-electrolysis mixed reactor, and a dosing device 8 is also arranged in the mixing reaction chamber. The dosing device 8 adjusts the pH value by adding diluted acid solution; the mud-water separation area 3 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com