Multi-technique coupling bio-toilet feces treatment system with subcritical hydrothermal liquidation as key point and method

A subcritical water and treatment system technology, applied in water/sewage multi-stage treatment, anaerobic digestion treatment, pyrolysis treatment of sludge, etc., can solve the problem of low harmless efficiency, long treatment period and low resource utilization efficiency and other problems, to ensure the effect of biological safety, fast reaction speed and strong biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

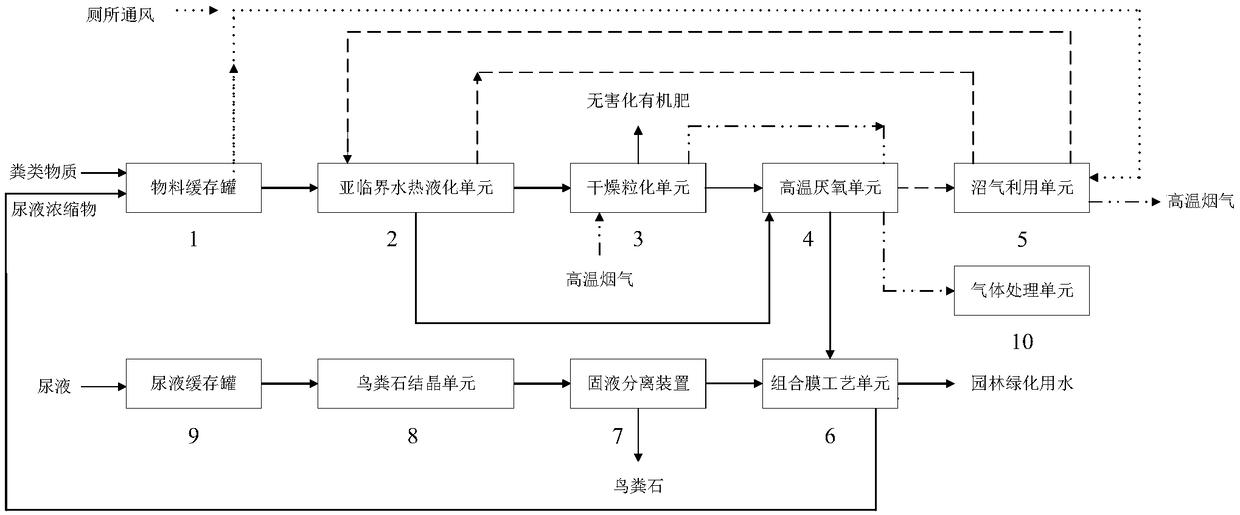

[0060] see figure 1 , The ecological toilet excrement and urine treatment system of the present invention is aimed at the situation that fecal matter and urine are treated separately, that is, what is stored in the material buffer tank 1 is fecal matter, and what is stored in the urine buffer tank 9 is urine.

[0061] It includes a material buffer tank 1 connected to a toilet or urinal, a subcritical hydrothermal liquefaction unit 2, a dry granulation unit 3, a high-temperature anaerobic unit 4, a biogas utilization unit 5, a combined membrane process unit 6, and a solid-liquid separation device 7 , struvite crystallization unit 8, urine buffer tank 9 and gas treatment unit 10.

[0062] Material buffer tank 1, subcritical hydrothermal liquefaction unit 2, dry granulation unit 3, high-temperature anaerobic unit 4 and biogas utilization unit 5 are connected sequentially through pipelines, urine buffer tank 9, struvite crystallization unit 8, solid-liquid The separation device 7...

Embodiment 2

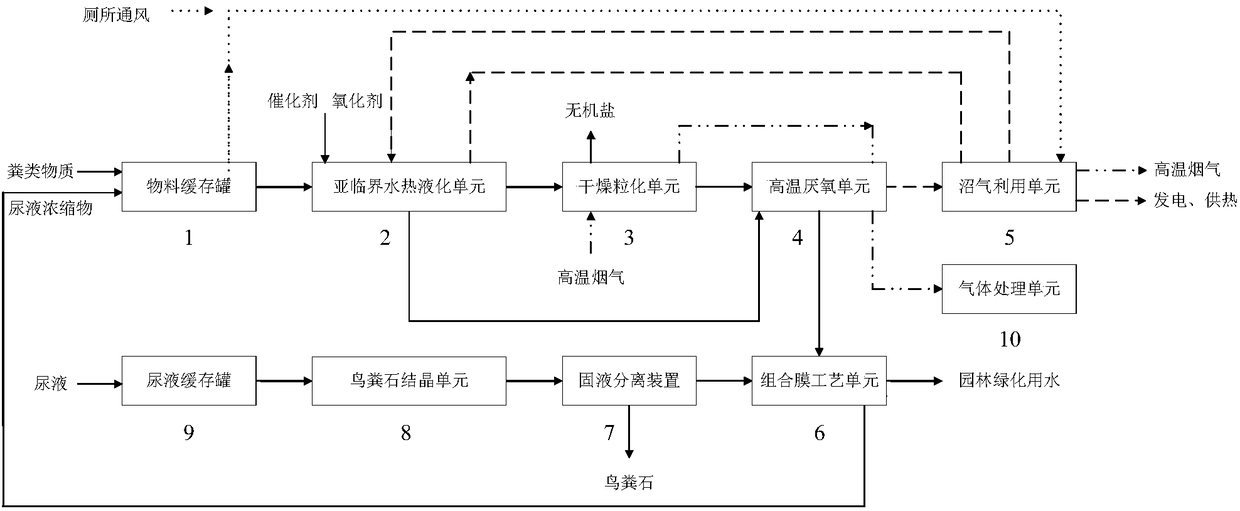

[0075] The difference between this embodiment and embodiment 1 is as figure 2 As shown, the specific differences are as follows:

[0076] The feces and urine concentrate enter the material buffer tank for pre-crushing, mixing and homogenization, so that the water content and viscosity of the mixed material meet the pumping conditions, and the pH is adjusted to 7.5-12.

[0077] When the homogeneous material in the material buffer tank 1 enters the subcritical hydrothermal liquefaction unit 2, a catalyst and an oxidant are added to the subcritical hydrothermal liquefaction unit 2, and the temperature is controlled at 180°C to 260°C to achieve inactivation of pathogens, etc. The molecular level is completely decomposed into CO 2 .

[0078] In addition to the heat generated by the biogas utilization unit 5 for the subcritical hydrothermal liquefaction unit 2, part of the biogas can be used for power generation, heat supply and other purposes.

[0079] The harmless mixed materi...

Embodiment 3

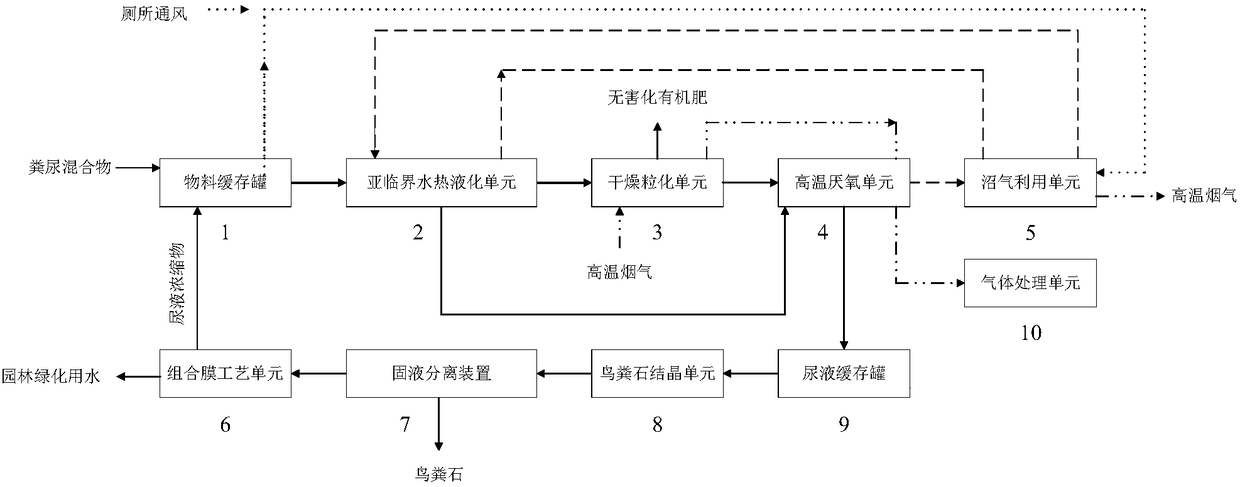

[0081] see image 3 , Different from Embodiment 1 and Embodiment 2, this embodiment is aimed at the situation that: the material buffer tank 1 stores a mixture of excrement and urine.

[0082] Material buffer tank 1, subcritical hydrothermal liquefaction unit 2, dry granulation unit 3, high temperature anaerobic unit 4, urine buffer tank 9, struvite crystallization unit 8, solid-liquid separation device 7 and composite membrane process unit 6 pass The pipelines are connected in sequence, and the combined membrane process unit 6 is connected to the material buffer tank 1; the high-temperature anaerobic unit 4 is also connected to the gas treatment unit 10 and the biogas utilization unit 5 respectively.

[0083] The method for utilizing the system of this embodiment to process the mixture of feces and urine specifically includes the following steps:

[0084] 1) The mixture of feces and urine enters the material buffer tank 1 for pre-crushing and homogenization, and adjusts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com