Methylamine wastewater pretreatment catalyst as well as preparation method thereof and application thereof in methylamine wastewater treatment

A wastewater treatment and catalyst technology, applied in the direction of oxidized water/sewage treatment, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems that the biochemical ability and toxicity have not been effectively improved, and achieve high catalytic activity and stability , biochemical ability and toxicity improvement, the effect of increasing biochemical ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Take the crushed specific surface area as 200-300m 2 5kg of magnetite / g was roasted at 800°C for 3h, and after cooling to 25°C, the magnetite was added with 30wt% nano-TiO 2 solution (impregnation solution), after 24 hours of drying at 120 ° C, the magnetite and nano-TiO 2 The mass ratio is 4:1, followed by calcination at 1200°C for 6h.

[0013] The prepared catalyst is molded by extrusion process and loaded into the catalytic oxidation reaction tower. The amount of the catalyst added is 1 / 2 of the volume of the catalytic oxidation reaction tower. After mixing the methylamine wastewater and hydrogen peroxide, pump it into the catalytic oxidation reaction tower. In the reaction tower, after staying in the tower for 60 minutes, it can be taken out of the tower, and conventional biochemical treatment can be carried out after the tower is taken out.

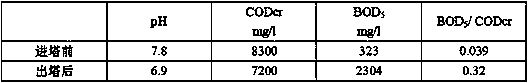

[0014] Analyze the water quality before and after entering the tower, and the analysis and test results are shown in the t...

Embodiment 2

[0018] Take the crushed specific surface area as 250-300m 2 5kg of magnetite / g was roasted at 700°C for 5h, and after cooling to room temperature (25°C), the magnetite was added with 30wt% nano-TiO 2 solution (impregnating solution), after 12 hours of drying at 105 ° C, the magnetite and nano-TiO 2 The mass ratio is 4:1, followed by calcination at 1200°C for 6h.

[0019] The prepared catalyst is shaped by extruding process and loaded into the catalytic oxidation reaction tower. The amount of the catalyst added is 2 / 3 of the volume of the catalytic oxidation reaction tower. After the methylamine wastewater and hydrogen peroxide are combined, the catalytic oxidation In the reaction tower, after staying in the tower for 40 minutes, it can be taken out of the tower, and conventional biochemical treatment can be carried out after the tower is taken out.

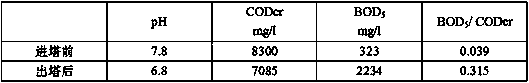

[0020] Analyze the water quality before and after entering the tower, and the analysis and test results are shown in the table...

Embodiment 3

[0024] Take the crushed specific surface area as 200-300m 2 5kg of magnetite / g was roasted at 800°C for 5h, and after cooling to room temperature (28°C), the magnetite was added with 35wt% nano-TiO 2 solution (impregnating solution), place it for 12 hours and then dry it at 120°C to make magnetite and nano-TiO 2 The mass ratio is 3:1, followed by firing at 1000°C for 7h.

[0025] The prepared catalyst is shaped by extruding process and loaded into the catalytic oxidation reaction tower. The amount of the catalyst added is 3 / 5 of the volume of the catalytic oxidation reaction tower. After mixing the methylamine wastewater and hydrogen peroxide, pump it into the catalytic oxidation reaction tower. In the reaction tower, after staying in the tower for 30 minutes, it can be taken out of the tower, and conventional biochemical treatment can be carried out after the tower is taken out.

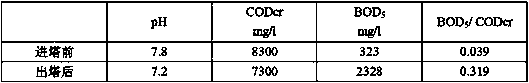

[0026] Analyze the water quality before and after entering the tower, and the analysis and tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com