Comprehensive recycling method for non-ferrous metal metallurgy acidic wastewater and zinc-containing residues

A non-ferrous metal and dirty acid technology, applied in the direction of improving process efficiency, etc., can solve problems such as low resource recovery rate, complex metal components, and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

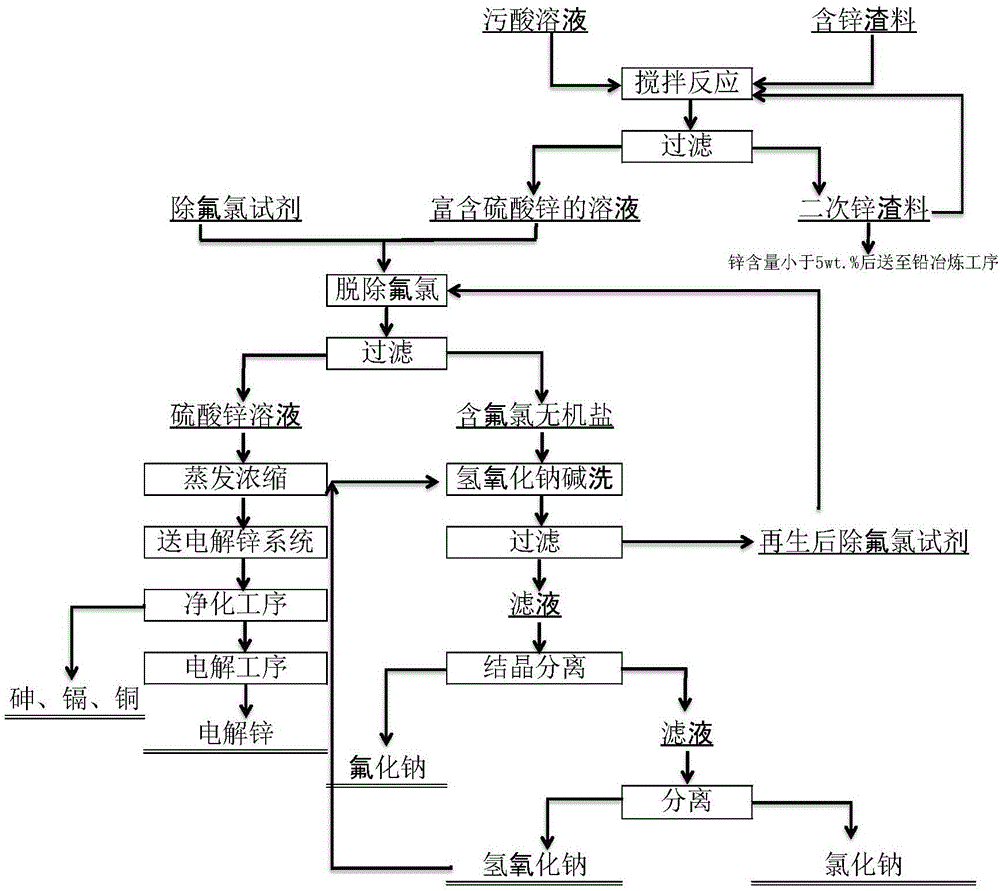

Method used

Image

Examples

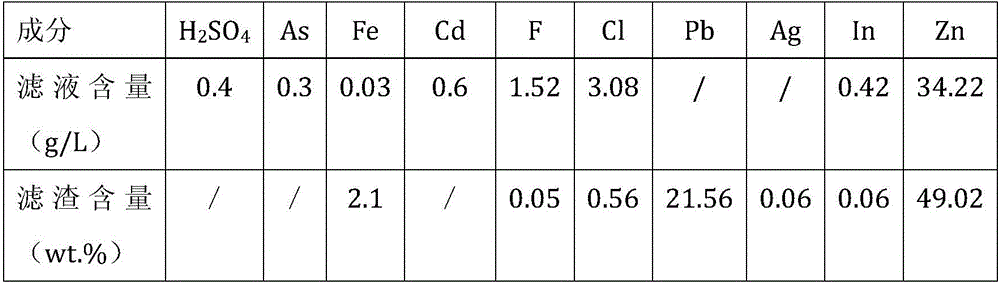

Embodiment 1

[0030] The sewage acid treated in this example is taken from the acid system of a zinc smelting enterprise, and the contents of the various components of the sewage acid are shown in the following table:

[0031] Element

h 2 SO 4

As

Fe

CD

F

Cl

Pb

Zn

Content (g / L)

60

0.3

0.05

0.6

1.5

2

0.1

0.15

[0032] Process this polluted acid with the method for sewage acid comprehensive treatment and recycling of the present invention, comprise the following steps:

[0033] Step 1: Batch the zinc-containing slag produced during the zinc smelting process of the plant, including the zinc scum floating on the surface during the ingot casting process and the secondary zinc oxide produced during the fuming process. The ingredients after batching are listed in the following table Show:

[0034] Element

Zn

In

Ag

Pb

Content (wt.%)

65

0.08

0.02

7.6

[0035] Add the z...

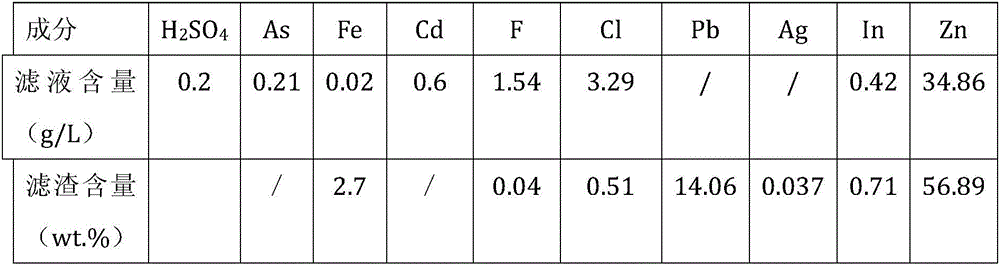

Embodiment 2

[0043] The sewage acid treated in this example is taken from the acid system of a zinc smelting enterprise, and the contents of the various components of the sewage acid are shown in the following table:

[0044] Element

h 2 SO 4

As

Fe

CD

F

Cl

Pb

Zn

Content (g / L)

60

0.3

0.05

0.6

1.5

2

0.1

0.15

[0045] Process this polluted acid with the method for sewage acid comprehensive treatment and recycling of the present invention, comprise the following steps:

[0046] Step 1: Batch the zinc-containing slag produced during the zinc smelting process of the plant, including the zinc scum floating on the surface during the ingot casting process and the secondary zinc oxide produced during the fuming process. Ingredients shown:

[0047] Element

Zn

In

Ag

Pb

Content (wt.%)

65

0.08

0.02

7.6

[0048] Add the zinc-containing slag material after batching to 1m 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com