Construction method of steel reinforced concrete chimney

A technology of reinforced concrete and construction method, which is applied in the processing of building materials, formwork/formwork/work frame, and on-site preparation of building components, etc. problems, to achieve the effect of shortening the construction period, saving the project cost and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The chimney of present embodiment is 80 meters high.

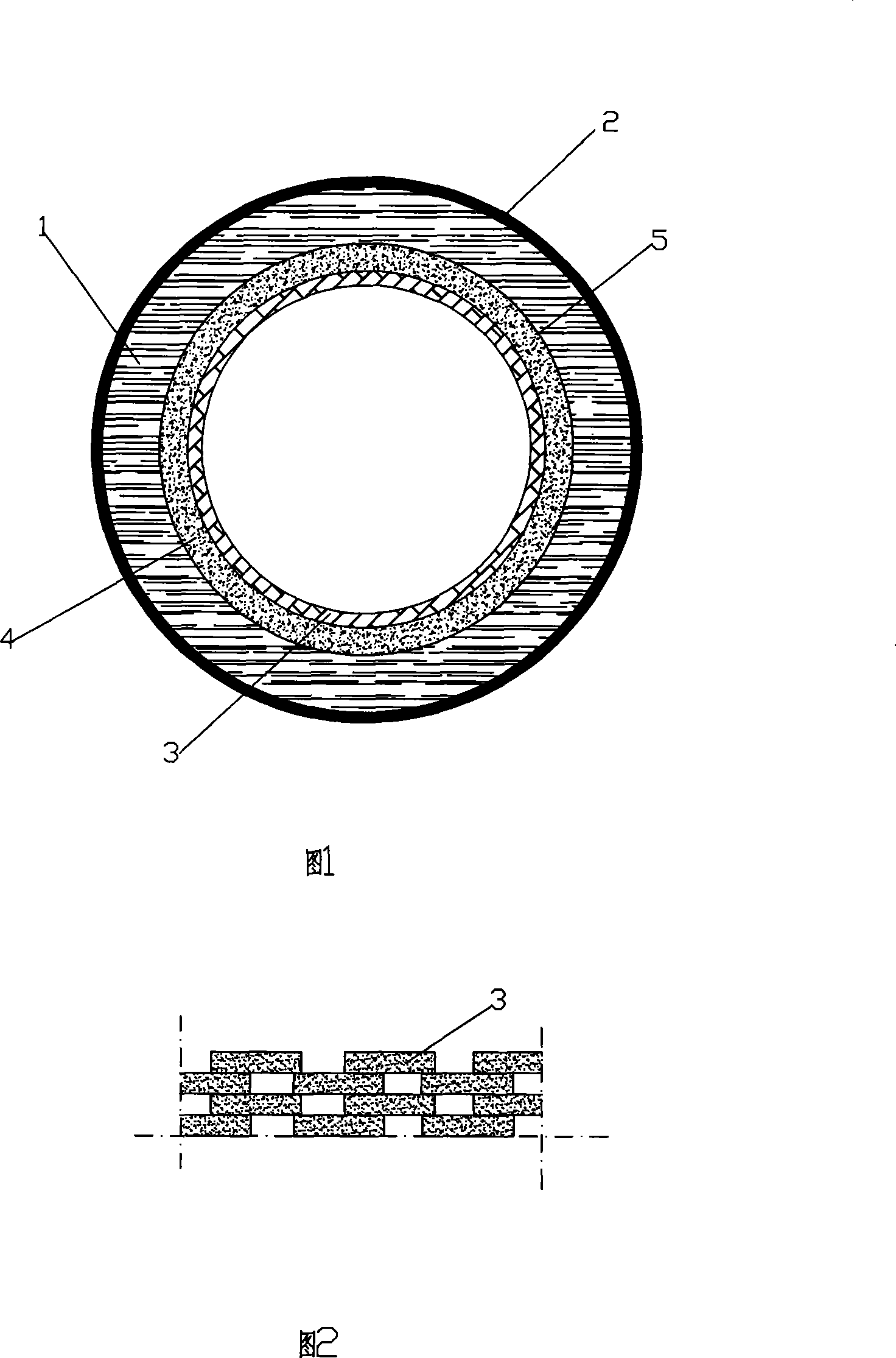

[0025] Fig. 1 is the effect diagram of the construction section of the present invention, and Fig. 2 is the lining structure diagram of the present invention, as shown in the figure: the inner circular surface of the reinforced concrete chimney of the present embodiment is clay refractory brick lining 3, and the outer circumference is aluminum quality shift Formwork 2 is placed, refractory brick lining 3 is provided with perlite block refractory layer 4 on the outer circle, and the outer circumference of refractory layer 4 is coated with anti-corrosion paint 5. Reinforced concrete 1 is poured between refractory layer 4 and displacement formwork 2 to form a chimney after solidification wall. The thickness of the refractory brick lining 3 in this embodiment is consistent with the width of the refractory bricks. When building masonry, the length direction of the refractory bricks is consistent with the circumferential ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com