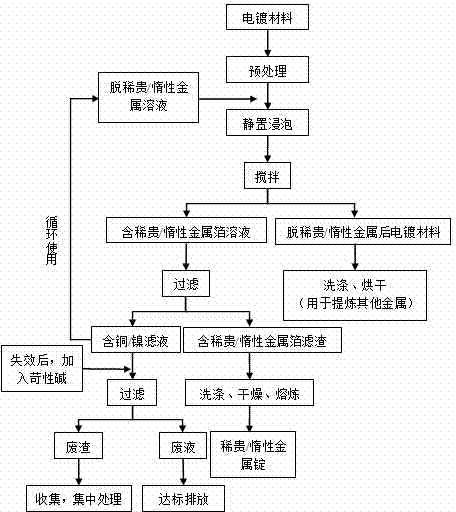

Method for recovering rare/inert metals from bottom electroplating copper/nickel material

A technology of inert metal and electroplating copper, which is applied in the field of industrial waste recycling, can solve problems such as unsuitability for industrial production, complex process flow, harsh reaction conditions, etc., and achieve the goal of being suitable for industrial production, simplifying process flow, and high gold recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Use a cleaning agent to remove the dust and oil on the surface of the waste circuit board, then rinse and dry it with clean water to obtain a clean waste circuit board; add complexing agent lactic acid and oxidant ferric chloride to the sulfuric acid aqueous solution to prepare a degold solution , wherein the mass concentration of sulfuric acid is 30%, the mass concentration of lactic acid is 1%, and the mass concentration of ferric chloride is 15%; the temperature is heated to 70°C, and the waste circuit board is left to soak in the degold solution for 4h, and then Stir for 30 minutes to complete the degolding; take out the circuit board, wash it, dry it, and collect it for refining other metals; filter the degolding solution to obtain the filter residue containing gold foil and copper-containing filtrate, wash the filter residue, dry it at high temperature and Smelting to obtain gold ingots, the recovery rate of gold reaches more than 98%; the copper-containing filtrat...

Embodiment 2

[0032] Use a cleaning agent to remove the dust and oil stains on the surface of the waste circuit board, then rinse and dry with clean water to obtain a clean waste circuit board; add complexing agent malic acid and oxidant potassium permanganate to sulfuric acid aqueous solution Gold solution, wherein the mass concentration of sulfuric acid is 20%, the mass concentration of malic acid is 3%, and the mass concentration of potassium permanganate is 13%; the temperature is heated to 50 ° C, and the waste circuit board is left standstill in the degold solution Soak for 2.5 hours, then stir for 20 minutes to complete the degolding; take out the circuit board, wash it, dry it, and collect it for refining other metals; filter the degolding solution to obtain the gold leaf-containing filter residue and copper-containing filtrate, and filter the filter residue Washing, high-temperature drying and smelting to obtain gold ingots, the recovery rate of gold is over 98%; the copper-containi...

Embodiment 3

[0034] Use a cleaning agent to remove the dust and oil stains on the surface of the waste circuit board, then rinse and dry it with clean water to obtain a clean waste circuit board; add complexing agent lactic acid and oxidant potassium permanganate to the sulfuric acid aqueous solution to configure solution, wherein the mass concentration of hydrochloric acid is 25%, the mass concentration of lactic acid is 4%, and the mass concentration of potassium permanganate is 17%; the temperature is heated to 50°C, and the waste circuit board is left to soak in the degold solution for 2h , and then stirred for 15 minutes to complete the degolding; the circuit board was taken out, washed, dried, and collected for refining other metals; the degolding solution was filtered to obtain the filter residue containing gold foil and the copper-containing filtrate, and the filter residue was washed and heated at high temperature Drying and smelting to obtain gold ingots, the recovery rate of gold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com