High-modulus asphalt modifier, high-modulus composite modified asphalt, asphalt mixture and preparation method thereof

A technology of composite modified asphalt and asphalt modifier, which is applied in the field of high modulus asphalt modifier, asphalt mixture and its preparation, and high modulus composite modified asphalt, which can solve the problem of crack resistance and oil consumption. Good balance, hard asphalt and other issues, to achieve the effect of maintaining physical and chemical stability, improving modulus and anti-rutting ability, and expanding market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

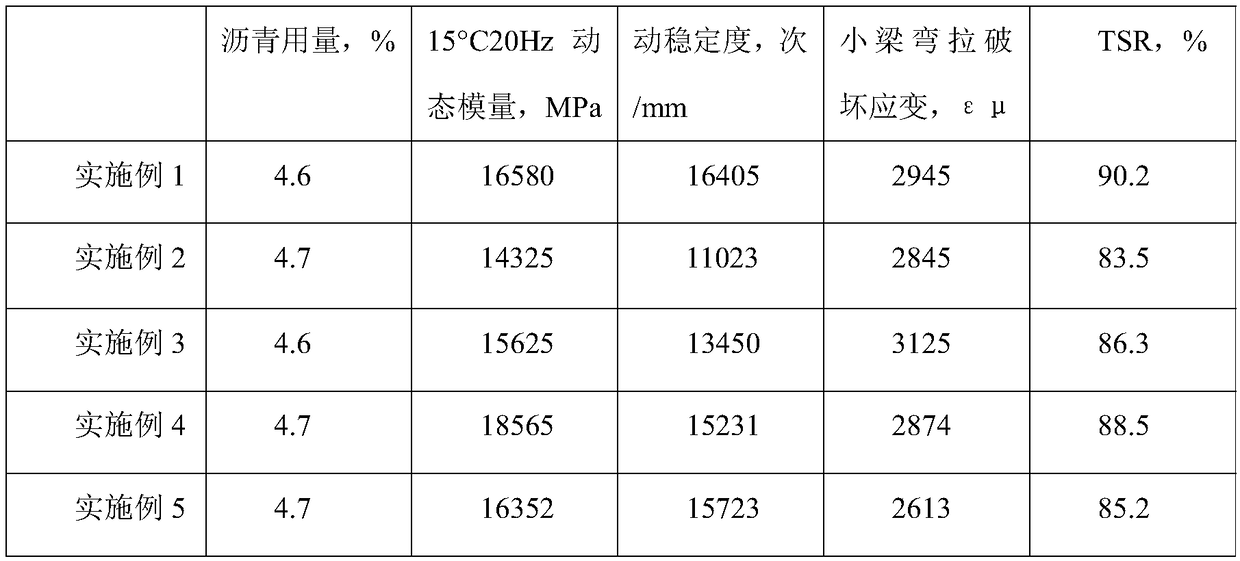

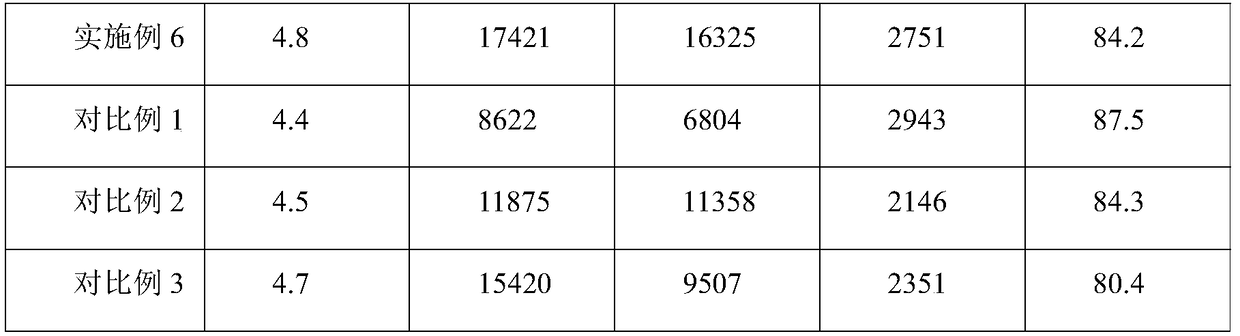

Examples

preparation example Construction

[0070] [Preparation method of high modulus asphalt modifier]

[0071] A preparation method of high modulus composite asphalt modifier, it comprises the steps:

[0072] (1), the rubber tire powder is desulfurized and plasticized to obtain the desulfurized rubber tire powder;

[0073] (2) Mix 40-60 parts of desulfurized rubber tire powder, 30-60 parts of polyolefin plastic particles, 0-20 parts of petroleum resin or solid pitch and 0-6 parts of stabilizer, and then carry out compound reaction through twin-screw extruder , and then extrude and granulate through a single-screw extruder;

[0074] Wherein, in step (1), the desulfurization and plasticization can use normal pressure screw plasticizer, screw plasticizer, dynamic desulfurization tank and other rubber powder desulfurization and plasticization equipment, and the desulfurization and plasticization temperature is 160-260°C.

[0075] In step (2), the temperature of the twin-screw extruder for compound reaction is 140-240°C...

Embodiment 1

[0112] The present embodiment provides a kind of preparation method of asphalt mixture, it comprises the steps:

[0113] 1. Preparation of high modulus asphalt modifier:

[0114] (1), the rubber tire powder is desulfurized and plasticized to obtain the desulfurized rubber tire powder;

[0115] (2), 60 kilograms of devulcanized rubber tire powder (Mooney 110, particle diameter is 30 orders), 40 kilograms of low-density polyethylene plastic particles (6% dosage modified asphalt softening point>100 ℃, melt index is 1.1g / 10min), 2 kilograms of petroleum resin (103 DEG C of softening point) and 2.6 kilograms of stabilizers are mixed and reacted by a twin-screw extruder, and then pelletized by a single-screw extruder to obtain a high modulus asphalt modifier.

[0116] Wherein, the stabilizer comprises the following components: 0.8 kg of nylon toughening agent, 0.8 kg of castor oil, 0.6 catties of sodium petroleum sulfonate, 0.4 kg of styrene, and 0.5 kg of maleic anhydride.

[01...

Embodiment 2

[0128] In this embodiment, "low-density polyethylene plastic particles" in the first step (2) section in embodiment 1 is replaced by "polypropylene". The rest of the parameters remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com