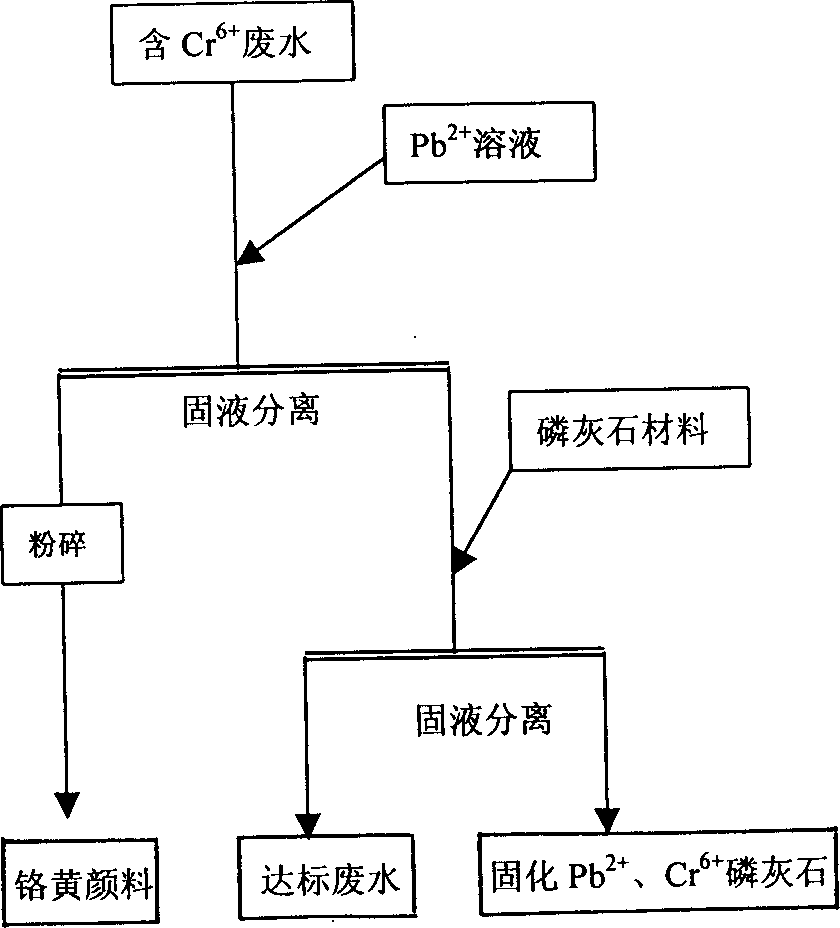

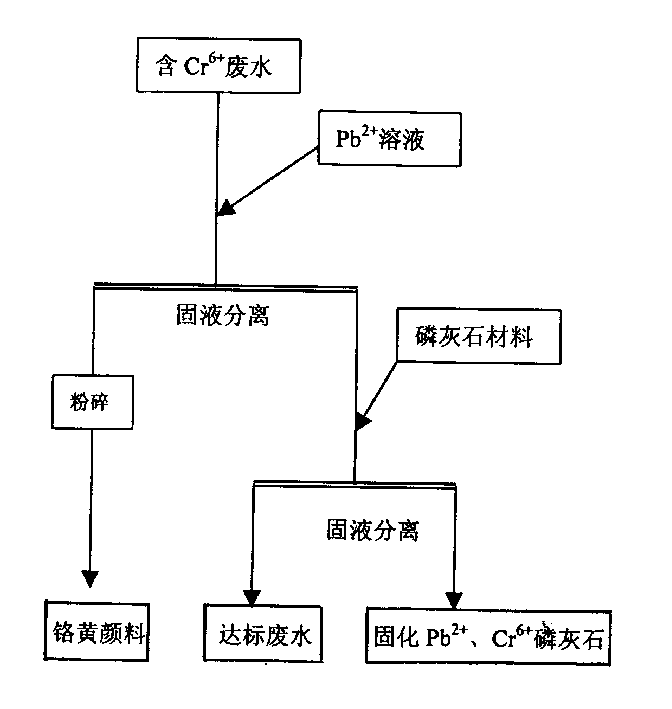

Process for recovering chrome yellow from chrome containing sewage

A treatment method and technology for chromium wastewater, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high separation cost, secondary water pollution, secondary pollution, etc. , to achieve the effect of high recovery rate, avoiding secondary pollution and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: chromium-containing wastewater is prepared by potassium dichromate, the concentration of chromium is 700.0mg / l, pH=4.30, in 1000ml wastewater, adding lead ion concentration is 20.72g / l wastewater 145ml, pH=1.26, in Under the conditions of pH 1.48 and temperature 40°C, stir for 10 minutes, separate the precipitate from water, and obtain 4.298 g of chrome yellow precipitate. The concentration of chromium in the wastewater is 0.68 mg / l, and the concentration of lead is 145.98 mg / l. The recovery rate of chromium is 99.89%, and the recovery rate of lead is 94.44%. In the wastewater from which chrome yellow is separated, add activated carbon fluoroapatite at a ratio of 17.46kg / t, and stir for 2 hours at PH=5.7 and normal temperature. , Filtration, the concentrations of lead and chromium ions in the filtrate are 0.51mg / l and 0.01mg / l respectively, and the waste completely meets the national emission standard of GB8978-1996.

Embodiment 2

[0012] Embodiment 2: chromium electroplating waste water, the concentration of chromium is 37.0mg / l, in 800ml chromium-containing waste water, add lead ion concentration and be 6.5ml of lead-containing solution waste water of 27.72g / l, pH=3.5, stir under the condition of temperature 40 ℃ In 10 minutes, 0.1755g of sediment was obtained, and the content of chrome yellow in the sediment was 88.15%, and the concentration of chromium in the waste water dropped to 2.4mg / l, and the recovery rate of chromium was 93.53%; the concentration of lead was 2.45mg / l, and the recovery of lead The rate is nearly 98.53%; in the wastewater from which chrome yellow was separated, add activated carbon fluoroapatite at a ratio of 6.2kg / t, stir for 2 hours at PH=5.7 and room temperature, and filter, the lead, The concentrations of chromium ions are 0.75mg / l and 0.21mg / l respectively, and the treated wastewater fully meets the discharge standard.

Embodiment 3

[0013] Embodiment 3: chromium-containing waste water is prepared by potassium dichromate, and the concentration of chromium is 100.0mg / l, and PH=5.42, and in 1000ml waste water, adding the waste water 19.5ml that lead ion concentration is 27.72g / l, PH=21.26, Then stir for 10 minutes at pH=2.7 and temperature at 40°C to obtain 0.615g of chrome yellow precipitate, the concentration of chromium in the wastewater is 1.17mg / l, the concentration of lead is 7.19mg / l, and the recovery rate of chromium is 98.81% , the lead recovery rate is 98.19%; in the waste water that separates chrome yellow, by the proportioning of 19.6kg / t, add active carbon fluoroapatite (the active carbon fluoroapatite of 1t waste water 19.6kg), at PH=5.4 , under room temperature conditions, stirred and mixed for 2 hours, filtered, and the concentrations of lead and chromium ions in the filtrate were measured to be 0.81mg / l and 0.01mg / l respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com