Passive plate type wet dust and mist removal device and treatment technology thereof

A technology of wet dust removal and mist removal device, which is applied in the direction of combination device, liquid separation agent, and dispersed particle separation. The effect of fast operation, simple device structure setting, and optimized treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

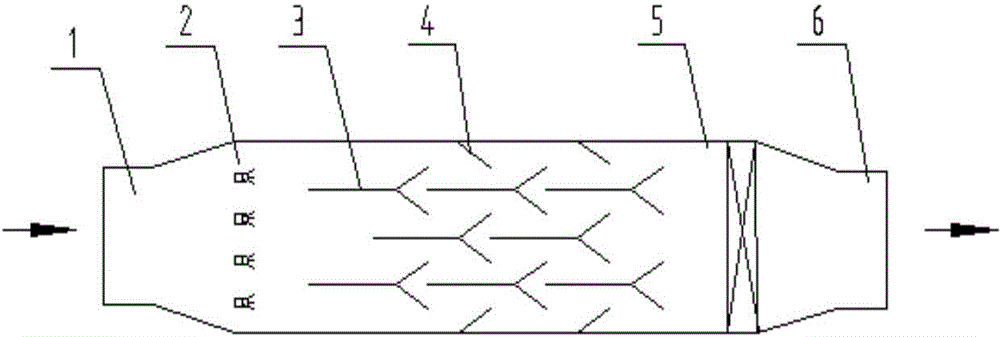

[0027] Such as figure 1 As shown, a passive plate-type wet dedusting and demisting device of the present invention comprises a housing with a smoke inlet channel 1 and a smoke outlet channel 6 at both ends, and an atomizing nozzle 2, a venturi The air guide channel and the mist eliminator 5, wherein the atomizing nozzle 2 is adjacent to the smoke inlet channel 1, and the mist eliminator 5 is connected to the smoke outlet channel 6.

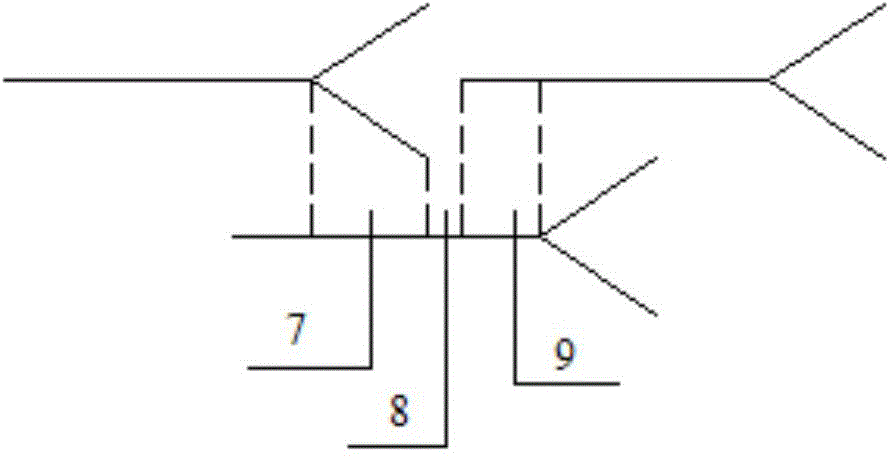

[0028] In the above embodiment, in order to enhance the condensation effect of the flue gas after passing through the Venturi gas channel, as figure 1 with figure 2 As shown, there are multiple groups of the Venturi air guide channels, and each group of the Venturi air guide channels is composed of a plurality of partitions 3 and air guide plates 4; the Venturi air guide channels include sequentially connected contraction sections 7. Throat 8 and diffuser section 9 , wherein the constricted section 7 is adjacent to the atomizing nozzle 2 , and ...

Embodiment 2

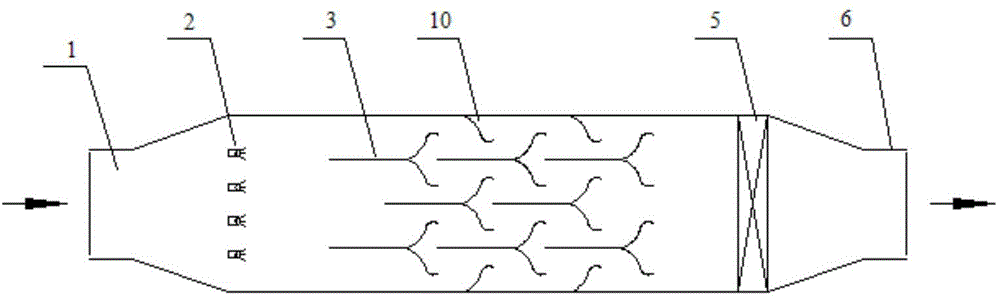

[0037] Such as image 3 with Figure 4 As shown, a passive plate type wet dust and mist removal device of the present invention has the same basic configuration and application as in Embodiment 1, wherein the air guide plate 4 is an arc-curved air guide plate 10, and the arc-curved plate 10 It forms a Venturi air guide channel with the partition 3. This setting can increase the number and intensity of collisions between the smoke and the wall of the Venturi air guide channel, accelerate the change of the movement direction and speed of the smoke gas, and increase the shrinkage and diffusion of the smoke gas. Thereby accelerating the condensation, and then more effectively promoting the condensation of tiny particles in the flue gas.

Embodiment 3

[0039] Such as Figure 5 with Image 6 As shown, a passive plate-type wet dedusting and demisting device of the present invention has the same basic configuration and application as that of Embodiment 1 or Embodiment 2, except that the Venturi air guiding channel is composed of multiple groups of Venturi tubes, Each set of venturi tubes is formed by connecting a plurality of partitions 3 and air guiding plates 4 .

[0040] In the above-mentioned embodiment, compared with Embodiment 1 or Embodiment 2, the gap of the Venturi air conduction channel is reduced, and the chance of the flue gas mixing to meet the Venturi air guide channel wall is increased, which is beneficial to increase the resistance of the Venturi air guide channel wall to large Droplet capture ability.

[0041] In the above embodiment, in order to enhance the removal effect of tiny particles in the flue gas, preferably, the distance between adjacent air guide plates 4 is 0.5 meters, the height of the air guide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com