Temperature adjustment device and method of focusing ring

一种调整装置、聚焦环的技术,应用在放电管、电气元件、等离子体等方向,能够解决线路布置复杂、影响装置处理反应效果、射频干扰等问题,达到避免射频干扰、改良处理工艺、良好传热性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

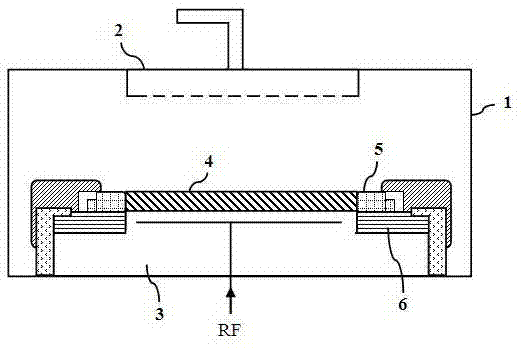

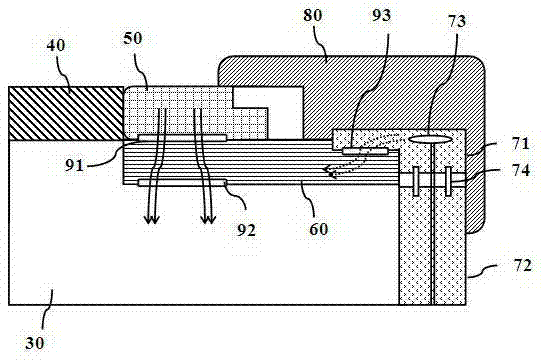

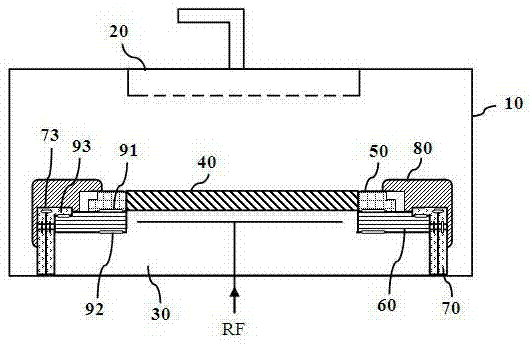

[0032] The invention provides a temperature adjustment device for a focus ring, which is suitable for a capacitively coupled plasma processing device. In the plasma processing device, such as figure 2 and image 3 , including the reaction chamber 10 whose interior is basically a vacuum environment, the top of the reaction chamber 10 is provided with an air inlet device such as a gas shower head 20 to connect with the reaction gas source, and the air inlet device is provided with a grounded upper electrode. The bottom in the reaction chamber 10 is provided with a pedestal 30 carrying the substrate 40, the pedestal 30 can be made of aluminum, and the interior is provided with a cooling medium pipeline to be connected to the cooling system; the pedestal 30 is provided with a lower electrode and applied with The radio frequency power forms a radio frequency electric field between the upper electrode and the lower electrode, and the reactive gas introduced into the reaction chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com