Method for in-situ generating inorganic nanoparticles in textile

An inorganic nanoparticle, in-situ generation technology, applied in textiles and papermaking, textile material processing, liquid/gas/vapor textile processing, etc. Inexpensive, good protective effect, easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

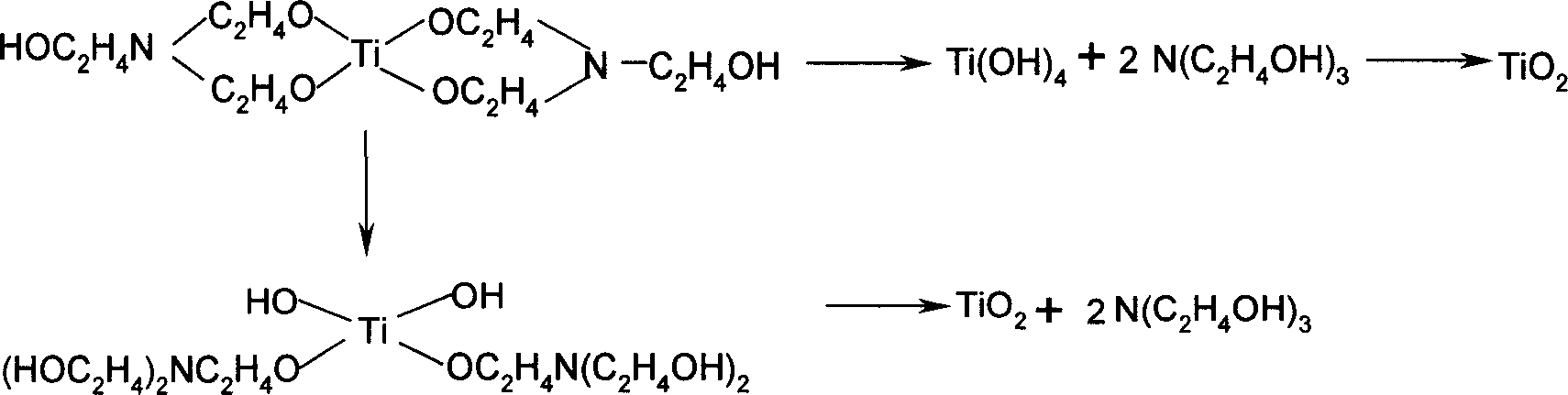

[0029] In situ generation of inorganic nanoparticle TiO in textiles 2 , At room temperature, under the condition of stirring, slowly drop 4.4ml of titanium tetrachloride into the ethanol solution dissolved in 40ml of triethanolamine to form a paste complex. After keeping the complex at about 30°C for a period of time, add deionized water to dissolve and make a saturated solution. Mix the prepared solution with 1-5% amino alcohol aqueous solution and textiles under stirring or ultrasonic dispersion, let the textiles be fully immersed in the solution, adjust the PH1-9 value, and at a certain temperature, by ultrasonic method, The sol of the anatase nano-titanium dioxide is obtained, and at the same time, the nano-anatase titanium dioxide can be obtained in situ in the textile.

Embodiment 2

[0031] In situ generation of inorganic nano-TiO in textiles 2 Particles, at room temperature, under stirring, slowly add 4.4ml of titanium tetrachloride dropwise into ethanol solution in which 40ml of triethanolamine is dissolved to form a paste complex. After keeping the complex at about 30°C for a period of time, add deionized water to dissolve and make a saturated solution. Mix the prepared solution with 1-5% amino alcohol aqueous solution and textiles under stirring or ultrasonic dispersion, let the textiles be fully immersed in the solution, adjust the pH value to 1-9, and add the mixed system to the hydrothermal reaction kettle In the method, the hydrothermal method is adopted, and the reaction temperature is 145° C. to 200° C. to prepare nano-titanium dioxide in the rutile crystal form in the textile in situ.

Embodiment 3

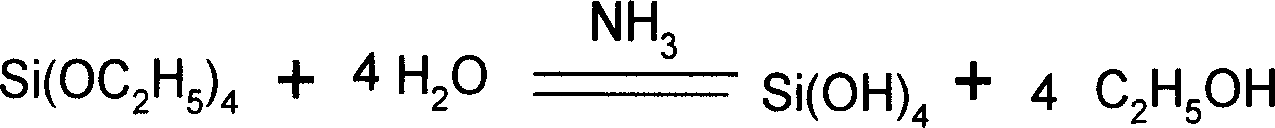

[0033] In situ generation of inorganic nano-SiO in textiles 2 Particles, first mix 8ml of ammonia water with 50ml of ethanol, and mix 8ml of tetraethyl orthosilicate with 50ml of ethanol. Then, under the condition of stirring or ultrasonic dispersion, add the prepared ethanol solution of ammonia water into the ethanol solution of ethyl orthosilicate to obtain a transparent solution, fully immerse the textile in the transparent solution, at 30°C, As the reaction progresses, the transparent solution becomes a sol, and a monodisperse nano-silica sol is prepared, and at the same time, nano-silica can be obtained in situ in the textile fabric fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com