A method of grafting polymer on glass surface

A technology for grafting polymers and glass surfaces, applied in the field of glass surface grafting and grafting polymer chains, can solve problems such as difficult industrial production, heavy pollution, and complicated processes, and achieve easy access, simple operation process, and grafting Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

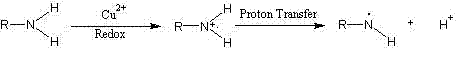

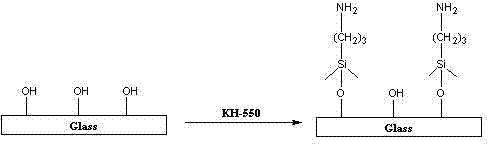

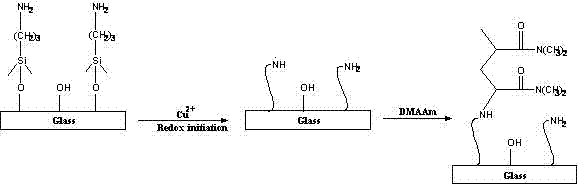

Method used

Image

Examples

Embodiment 1

[0033] 0.05g CuSO 4 and 10g of DMAAm were dispersed in 10g of distilled water to make a reaction solution, and then the glass flakes treated by the method of step (1) were placed in the reaction solution, and reacted at 80°C for 4h to obtain a PDMAAm-grafted glass flake sample , the mass percent concentration of KH-550 in the PAAm aqueous solution in step (1) is 5%; the mass percent concentration of the PAAm aqueous solution is 0.05%; the glass flake quality before the reaction is 0.5165g, and the glass flake quality after the reaction is 0.5179g, a weight gain of 0.0014g, and a weight gain rate of 0.2710%; through infrared spectroscopy analysis, from Figure 5 It can be seen that the wave number is about 2900cm -1 for -CH 3 characteristic absorption peak, while 1620cm -1 Nearby is the characteristic absorption peak of C=O, 1250cm -1 The characteristic absorption peak of C-N appears nearby, indicating that PDMAAm has been successfully grafted onto the glass surface.

Embodiment 2

[0035] 0.05g CuSO 4 Disperse 10g of DMAPMA in 10g of distilled water to make a reaction solution, then place the glass sheet treated by the method of step (1) in the reaction solution, and react at 80°C for 4h to prepare a PDMAPMA-grafted glass sheet sample , the mass percent concentration of KH-550 in the PAAm aqueous solution in step (1) is 2%; the mass percent concentration of the PAAm aqueous solution is 0.1%; the glass flake quality before the reaction is 0.4250g, and the glass flake quality after the reaction is 0.4266g, a weight gain of 0.0016g, and a weight gain rate of 0.3765%; through infrared spectroscopy analysis, from Figure 6 It can be seen that the wave number is about 2950cm-1 for -CH 3 characteristic absorption peak, while 1650cm -1 Nearby is the characteristic absorption peak of C=O, 1535cm -1 The N-H characteristic absorption peaks appear nearby, indicating that PDMAPMA has been successfully grafted onto the glass surface.

Embodiment 3

[0037] 0.05g CuSO 4 Disperse 0.1g of MMA in 10g of distilled water to make a reaction solution, then place the glass sheet treated by the method of step (1) in the reaction solution, and react at 80°C for 4h to obtain a PMMA-grafted glass sheet Sample, the mass percent concentration of KH-550 in the PAAm aqueous solution in step (1) is 1%; the mass percent concentration of the PAAm aqueous solution is 0.2%; It is 0.4353g, and the weight gain is 0.0009g, and the weight gain rate is 0.2072%; Figure 7 It can be seen that the wave number is about 2920cm -1 for -CH 3 characteristic absorption peak, while 1660cm -1 Nearby is the characteristic absorption peak of C=O, indicating that PMMA has been successfully grafted onto the glass surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com