Finishing method of long-acting washable antibacterial fabric

A fabric finishing and washable technology, which is applied in the field of textile engineering, can solve the problems of fabric damage and expensive silver, and achieve the effects of strong reactivity, high binding fastness, and broad antibacterial spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A long-acting washable and antibacterial fabric finishing method, comprising the steps of:

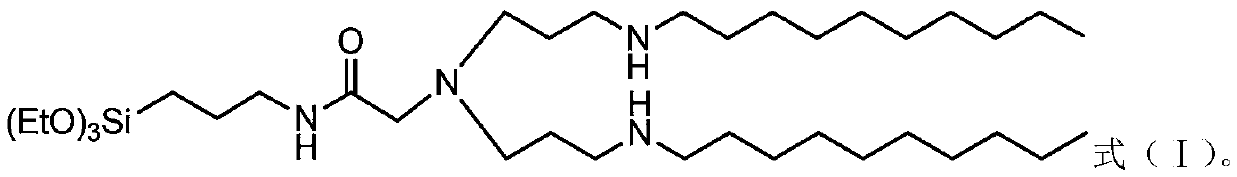

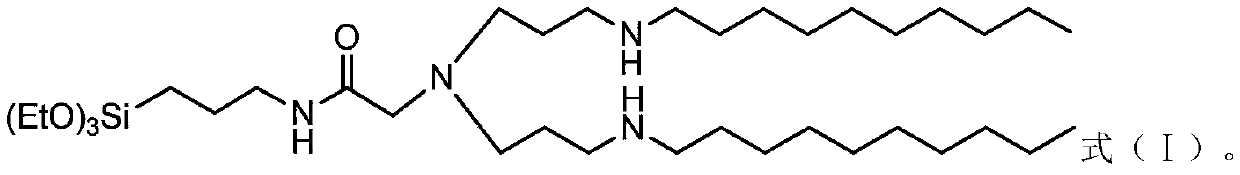

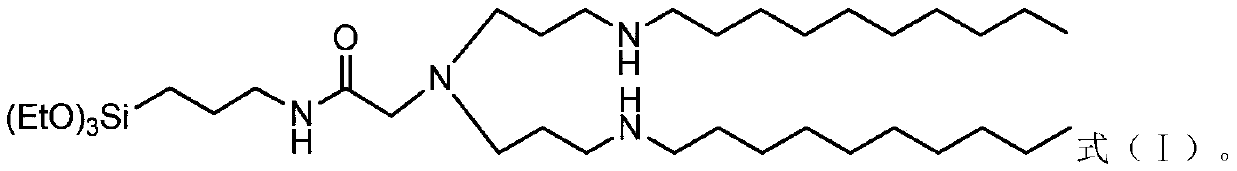

[0044] 1. Preparation of organic-inorganic composite lipid: Dissolve 15g of N,N-bis(decylpropylamino)glycine in 100ml of triethylamine, then add 15g of aminopropyltriethoxysilane, add 6g of condensate at 0°C Reagent benzotriazol-1-yl-oxytripyrrolidinylphosphine hexafluorophosphate (PyBOP) was reacted for 6 hours, and after the reaction was completed, the organic-inorganic composite lipid was collected by silica gel column chromatography;

[0045]2. Preparation of antibacterial siliceous bodies: take 0.15g of organic-inorganic composite lipid, dissolve the organic-inorganic composite lipid in 10ml of chloroform, evaporate and remove the chloroform to obtain a lipid-like film, filter through polycarbonate Membrane liposome extruder is extruded, and the pore size of filter membrane is 1.0 μm, obtains antibacterial siliceous body solution;

[0046] 3. Surface treatment of cotton fa...

Embodiment 2

[0049] A long-acting washable and antibacterial fabric finishing method, comprising the steps of:

[0050] 1. Preparation of organic-inorganic composite lipid: Dissolve 10g of N,N-bis(decylpropylamino)glycine in 100ml of pyridine, then add 10g of aminopropyltriethoxysilane, add 4g of condensate at -10°C The reagent dicyclohexylcarbodiimide (DCC) was reacted for 4 hours, and after the reaction was completed, the organic-inorganic composite lipid was collected by silica gel column chromatography;

[0051] 2. Preparation of antibacterial siliceous body: take 0.1g of organic-inorganic composite lipid, dissolve the organic-inorganic composite lipid in 10ml of chloroform, evaporate and remove the chloroform to obtain a lipid-like film, filter through polycarbonate Membrane liposome extruder is extruded, and the pore diameter of filter membrane is 0.5 μ m, obtains antibacterial siliceous body solution;

[0052] 3. The silk fabric is treated with low-temperature plasma, the condition...

Embodiment 3

[0055] A long-acting washable and antibacterial fabric finishing method, comprising the steps of:

[0056] 1. Preparation of organic-inorganic composite lipid: Dissolve 20g of N,N-bis(decylpropylamino)glycine in 100ml of triethylamine, then add 20g of aminopropyltriethoxysilane, add 8g of condensate at 10°C The reagent N,N'-carbonyldiimidazole (CDI) was reacted for 8 hours, and after the reaction was completed, the organic-inorganic composite lipid was collected by silica gel column chromatography;

[0057] 2. Preparation of antibacterial siliceous body: take 0.2g of organic-inorganic composite lipid, dissolve the organic-inorganic composite lipid in 10ml of chloroform, evaporate and remove the chloroform to obtain a lipid-like film, filter through polycarbonate Membrane liposome extruder is extruded, and the pore size of filter membrane is 1.0 μm, obtains antibacterial siliceous body solution;

[0058] 2. The hemp fabric is surface-treated with low-temperature plasma, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com