PVC (polyvinyl chloride) impact modifier opaque high-impact-resistance MBS and preparation method thereof

An impact modifier and high-impact technology, which is applied in the production and preparation of PVC additives, can solve problems such as difficulty in spraying, low impact strength, and difficulty in coagulation in post-treatment processes, so as to improve grafting effect and enhance practicality. Performance, the effect of solving difficult agglomeration or spraying difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

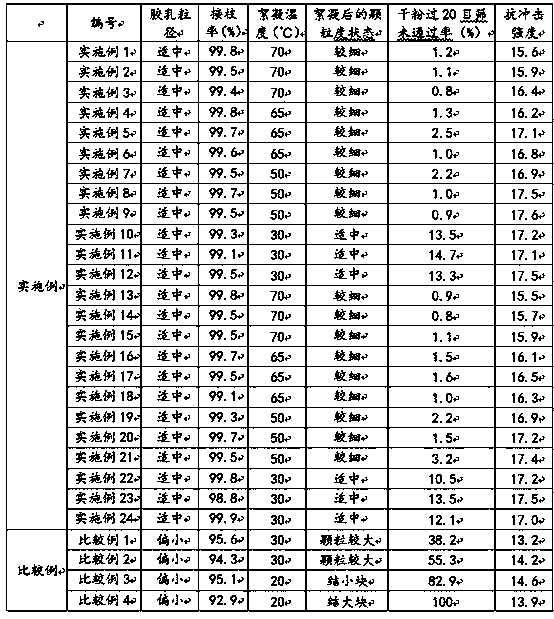

Examples

Embodiment 1

[0029] (1) Add formula water, emulsifier, protective colloid (0.01% by weight of monomer) alkali, inorganic salt, molecular weight regulator, crosslinking agent, initiator in the reaction kettle, then close the reaction kettle cover, put Butadiene is injected into the reactor;

[0030] (2) The temperature of the reaction kettle is raised to 65°C, and the reaction is about 20 hours. When the pressure in the reaction kettle drops to 0.5MPa, the temperature is raised to 75°C, and the reaction is continued for about 4 hours to 0.1-0.2MPa. After confirming that the reaction is complete, the temperature is lowered to At 65°C, the reactor returned to normal pressure, and the inner layer accounted for 80%;

[0031] (3) Continue to add emulsifier, protective colloid (0.01% by weight of monomer), the mixture of outer layer monomer styrene (4.0%), acrylate (2.0%) and methyl methacrylate ( 14%), continue to react for 1-3 hours until the reaction is completed, and the outer layer accounts...

Embodiment 2

[0034] The pure butadiene in step (1) in Example 1 is changed to 97 / 3 of butadiene / styrene, and the remaining conditions are the same as in Example 1.

Embodiment 3

[0036] The pure butadiene in step (1) in Example 1 is changed to butadiene / styrene as 95 / 5, and the remaining conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com