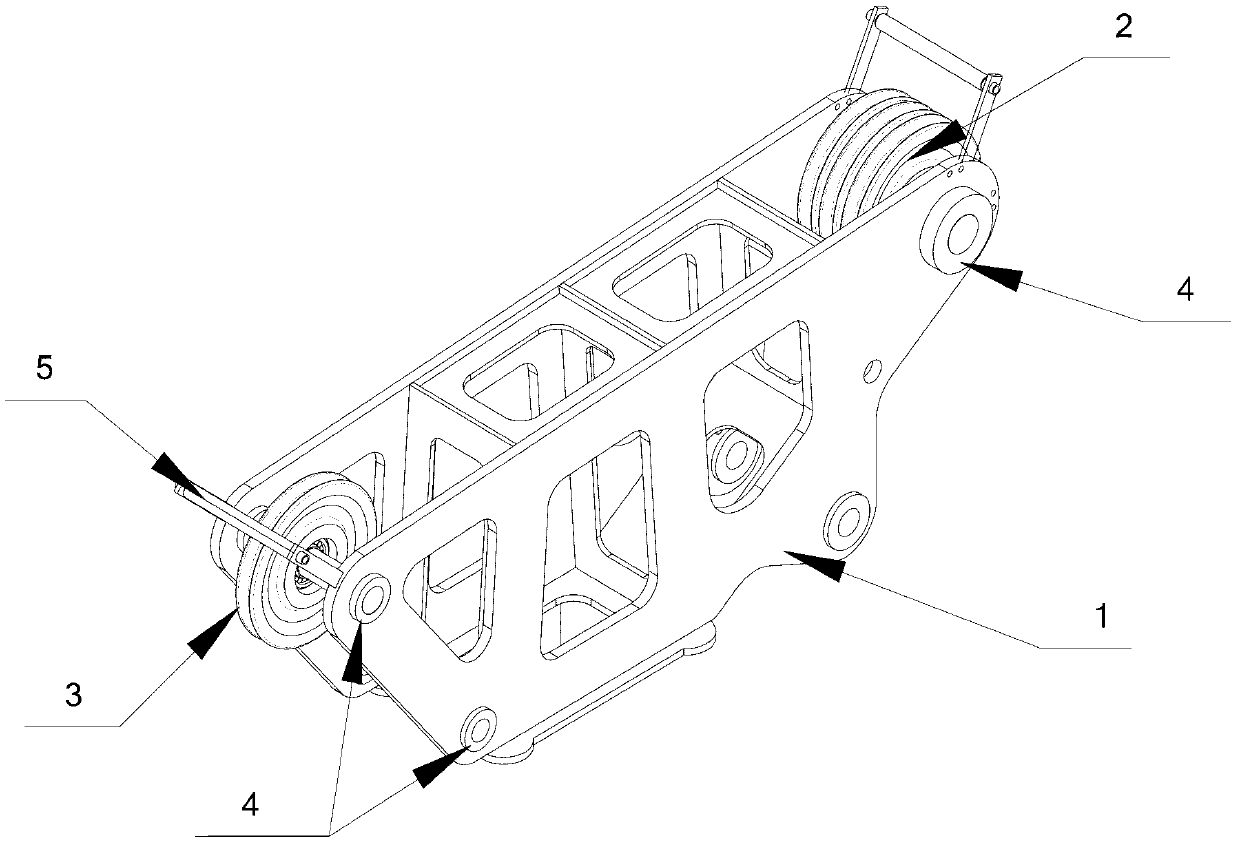

Crawler-type dynamic compactor and gooseneck boom device thereof

A technology of goose head and installation position, applied in the field of structural design of crawler-type construction machinery, can solve the problems that it is difficult to meet the requirements of the strength, stiffness and stability of the dynamic compactor, and affects the safety and service life of the whole vehicle. The effect of enhancing strength and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

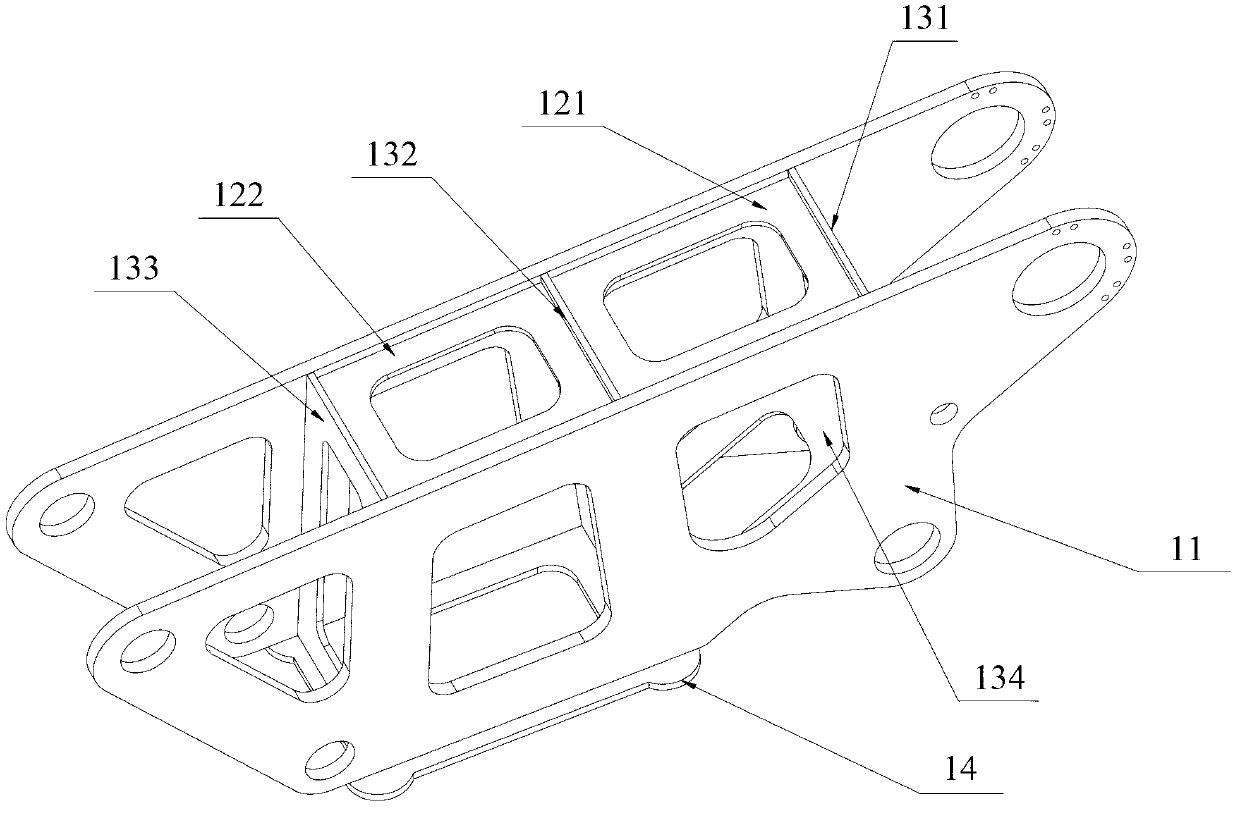

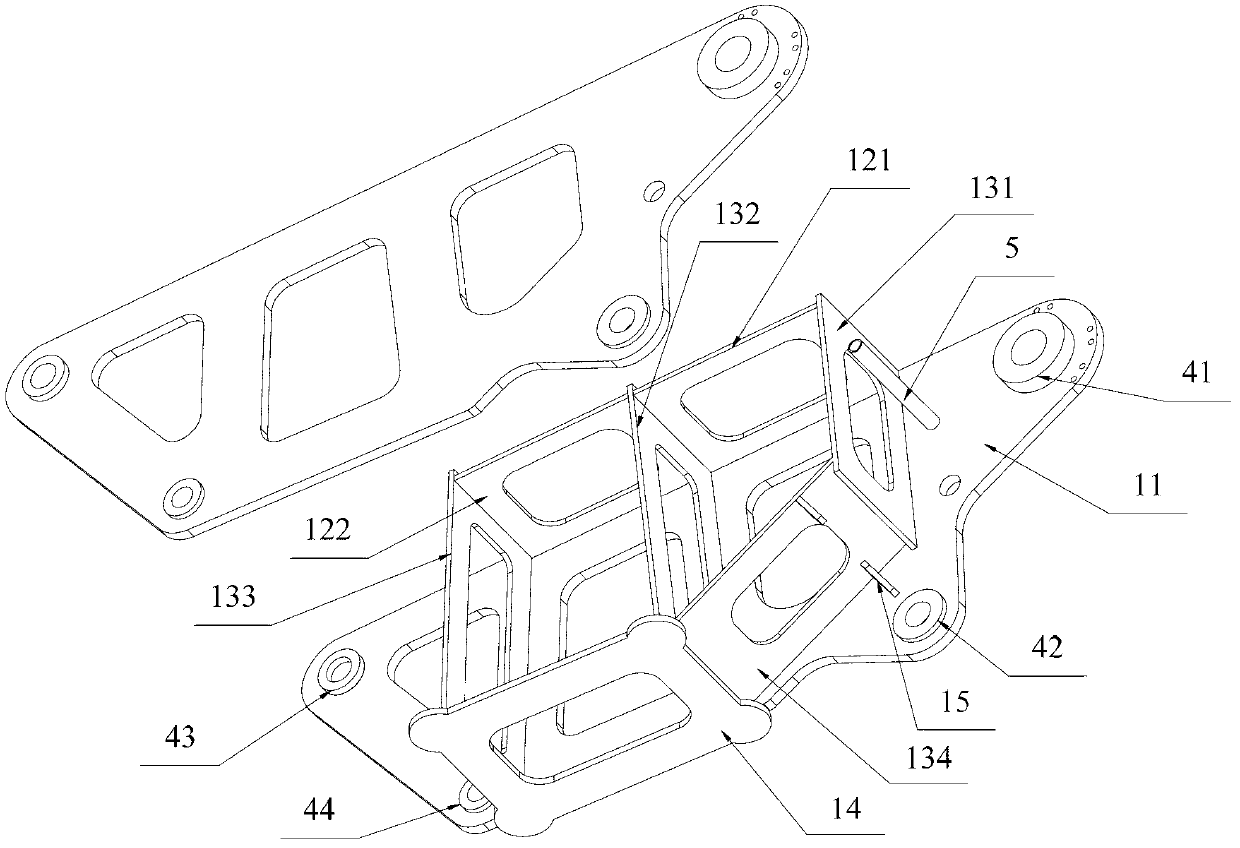

[0051] The core of the present invention is to disclose a goose head device, which can enhance the strength, stability and fatigue resistance of the overall structure under load conditions, thereby prolonging the service life of the goose head.

[0052] For ease of understanding, the technical terms involved in the present invention are now explained as follows:

[0053] Boom: The boom is a structural member used to support the weight of the weight, hook and decoupler. The jib generally adopts a truss structure, which is divided into upper jib, lower jib and standard jib.

[0054] Goose head: The function of the goose head is to fix the pulley, change the direction of movement of the wire rope, and support parts for lifting and dropping the weight.

[0055] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com