Workpiece reversing device and workpiece placing equipment provided with same

A technology of reversing device and workpiece, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of long time, reduce product quality, and fail to meet the requirements of production capacity, so as to avoid quality degradation, overcome wear and improve production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

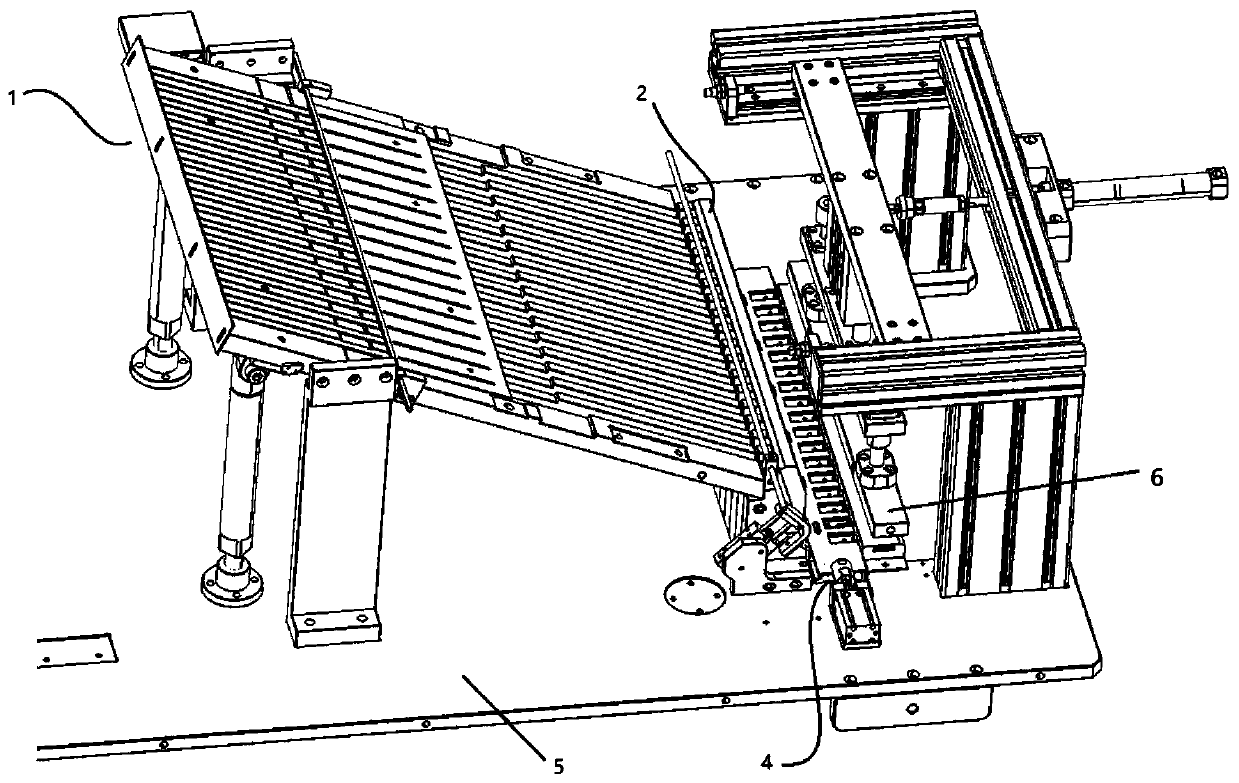

[0047] This embodiment provides a workpiece pendulum device, such as figure 1 As shown, the workpiece swinging equipment includes a base 5 and a workpiece feeding device, a workpiece reversing device and a workpiece retrieving device 6 arranged on the base 5. The workpiece feeding device includes several feeding troughs, and the workpiece is transported to the workpiece in the feeding chute. In the reversing device, the reversing is performed in the reversing device and continues to be transported to the storage tray. The workpiece retrieving device 6 includes a retrieving arm 61, and the workpiece is taken out from the retrieving tray by using the retrieving arm 61. Workpiece placement sequence The workpieces are placed in the swing tray, so that the output workpieces meet the requirements of the swing direction and are smoothly transported to the next station.

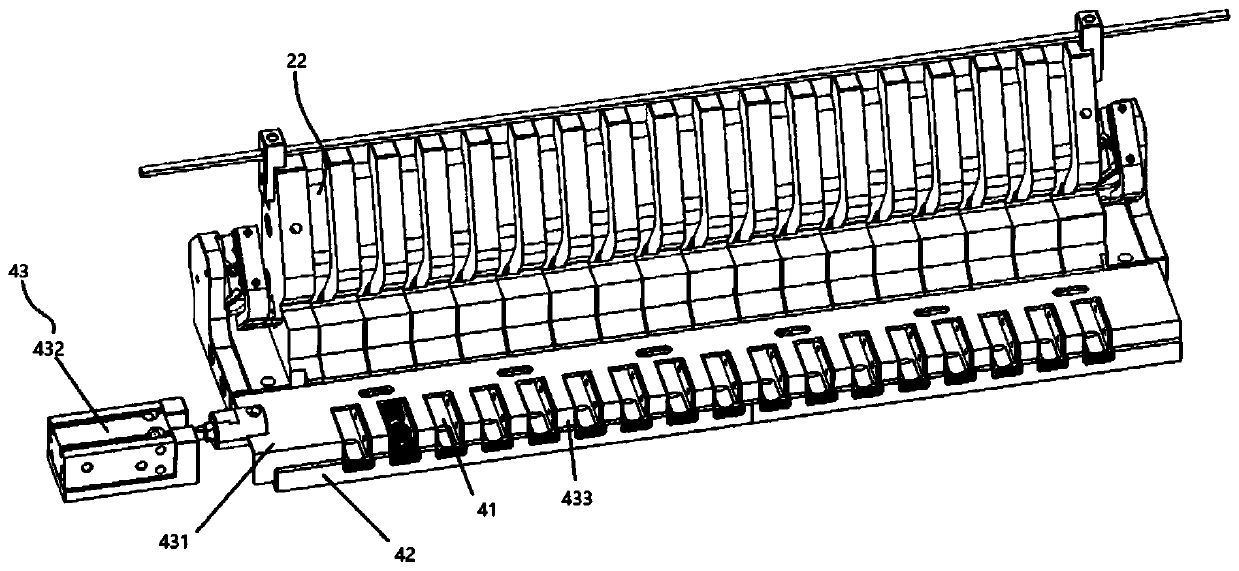

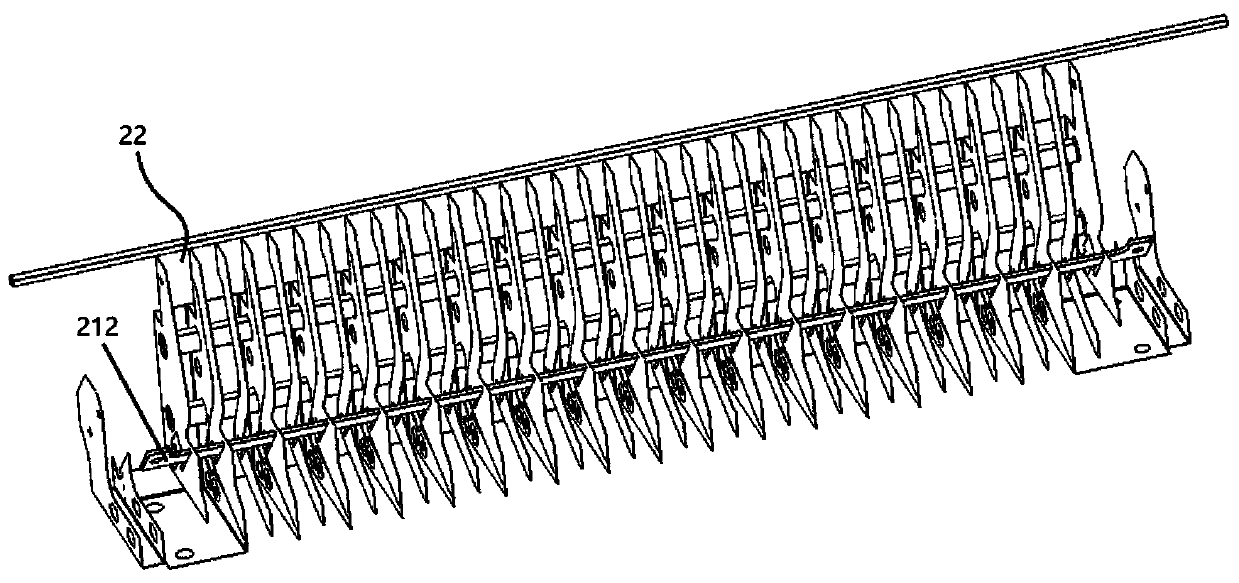

[0048] Such as figure 1 and figure 2 As shown, the workpiece reversing device in this embodiment is now describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com