Pizza forming equipment

A molding equipment and pizza technology, applied in the field of pizza molding equipment, can solve the problems of low pizza working efficiency, long pizza baking time, and inability to adapt to mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

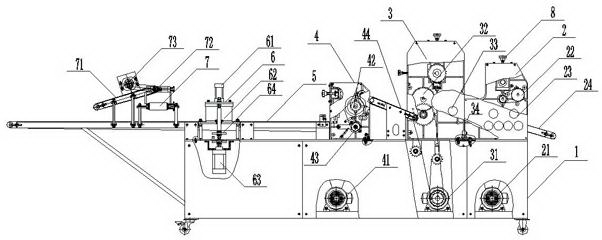

[0015] Such as figure 1 A kind of pizza molding equipment as shown, comprises frame 1, the initial noodle pressing mechanism 2 that is installed on the frame, secondary noodle pressing mechanism 3, three noodle pressing mechanism 4, conveyer belt 5, cake mold mechanism 6. The initial pressing surface mechanism 2 includes an initial pressing surface driving motor 21, an initial pressing surface driving gear set 22 connected with the initial pressing surface driving motor, an initial pressing surface roller set 23 connected with the initial pressing surface driving gear set, and an installation The primary feeding belt 24 connected to the primary pressing surface transmission gear set before the initial pressing surface roller group; the secondary pressing surface mechanism 3 includes a secondary transmission motor 31, a secondary gear set 32 connected to the secondary transmission motor , the secondary pressing roller group 33 that is connected with the secondary gear set, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com