Bulk-cargo-vehicle-mounted self-unloading system

A self-unloading and self-unloading device technology, which is applied in the direction of freight vehicles, motor vehicles, loading and unloading vehicle arrangements, etc., can solve the problems of incomplete unloading of bulk cargo and incomplete automation, so as to achieve improved efficiency, low cost, The effect of simple car body structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

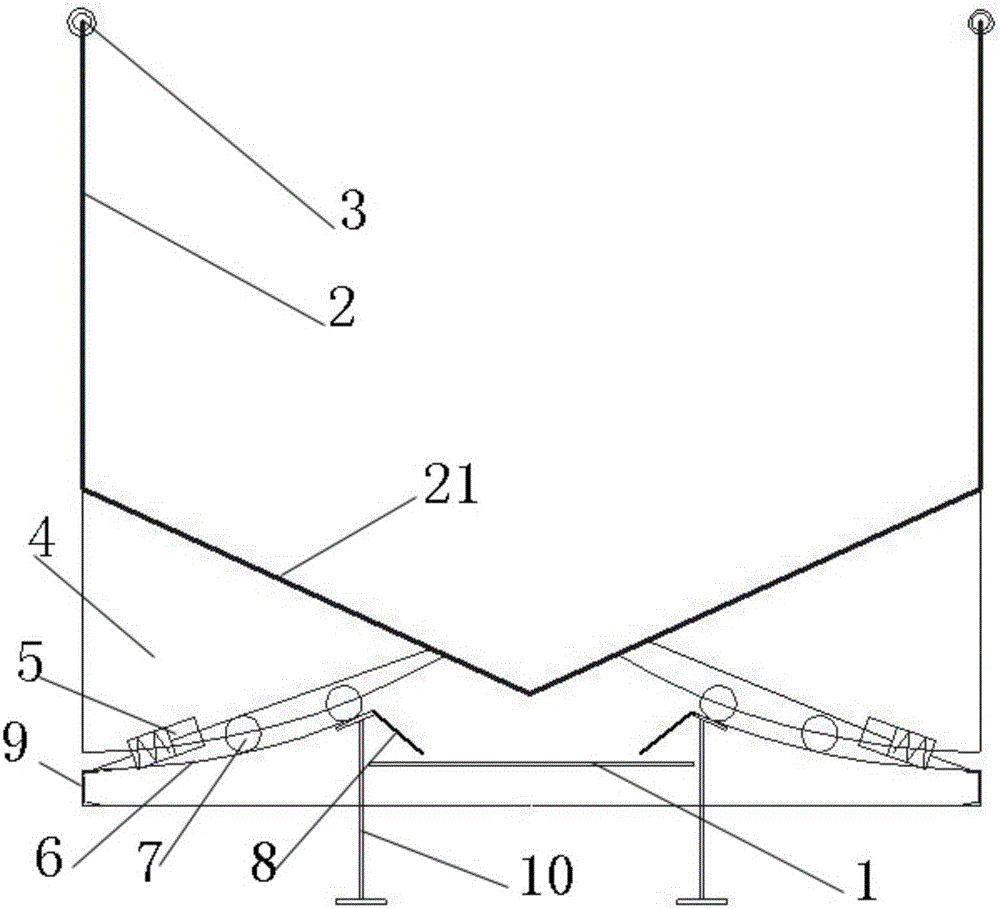

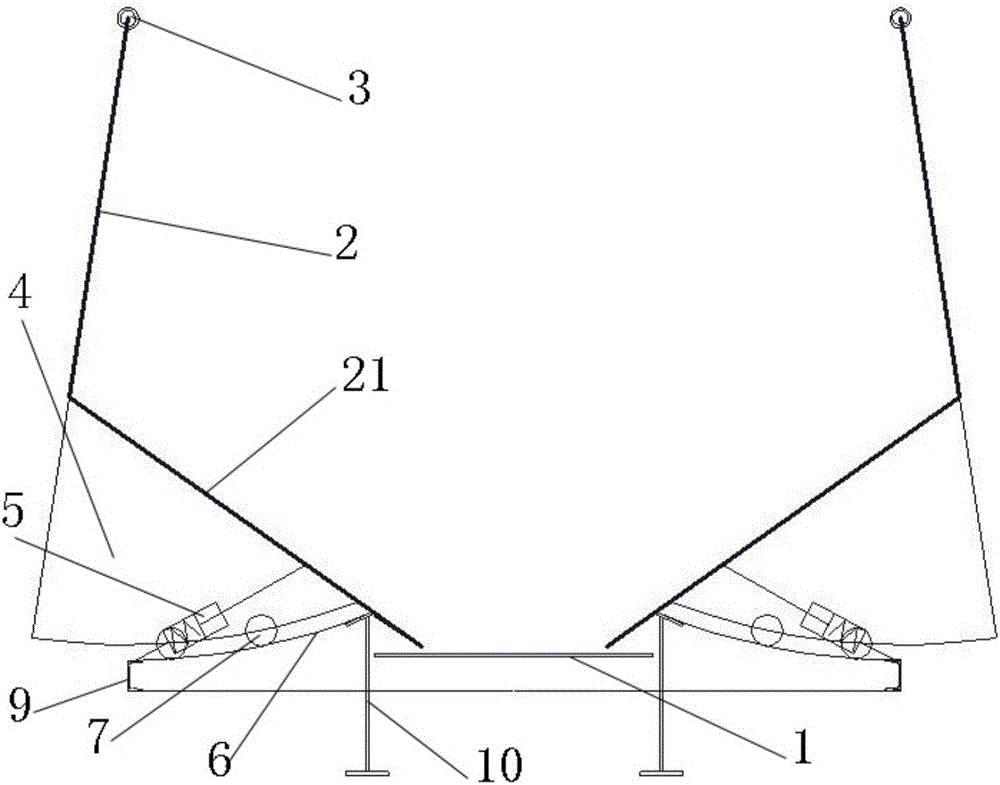

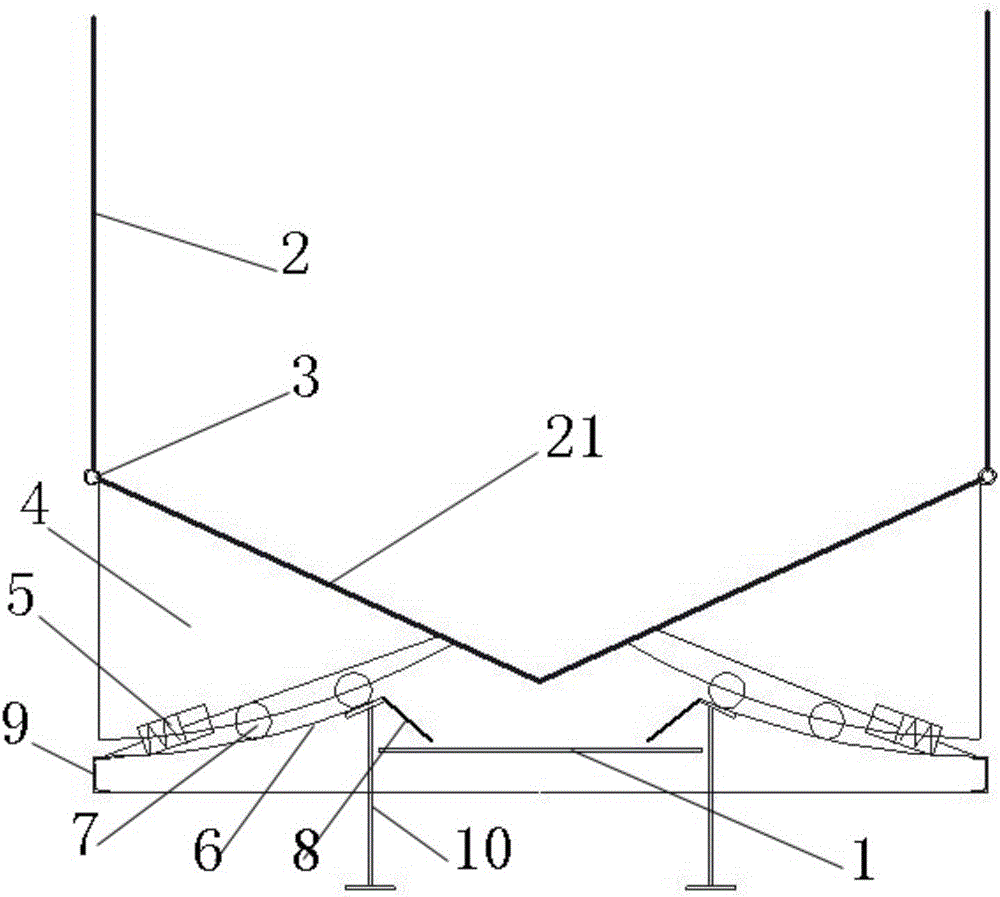

[0026] The present invention will be further described below in conjunction with specific embodiments, as figure 1 , 2 As shown, the first embodiment of the present invention is: a vehicle-mounted self-unloading system for bulk cargo, including three parts: a horizontal self-unloading device 1, a bottom-opening compartment and a movable compartment control device, and the horizontal self-unloading device 1 is arranged on The self-unloading track or conveyor belt between the two longitudinal beams at the bottom of the carriage is used to carry the bulk cargo that falls when the upper carriage is opened. The horizontal self-unloading device 1 partly belongs to the prior art, and will not be described in detail here.

[0027] The bottom-opening compartment does not touch the bottom frame of the compartment, and there is a certain distance between them. The bottom-opening compartment is composed of two symmetrical movable compartments 2. The movable compartment 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com