Disassembly line and disassembly technology of large scrapped automobile

An automobile dismantling and assembly line technology, which is applied in the direction of vehicle scrap recycling, motor vehicle, solid waste removal, etc., can solve the problems of poor safety, high labor intensity of dismantling personnel, and lack of equipment dismantling process, so as to reduce labor intensity. , The circulation equipment is reasonably configured and the safety is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

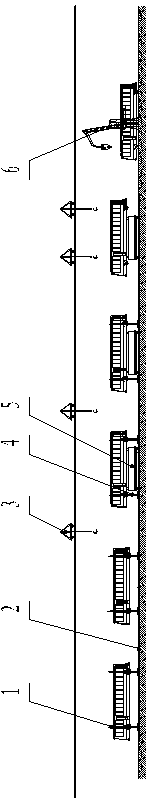

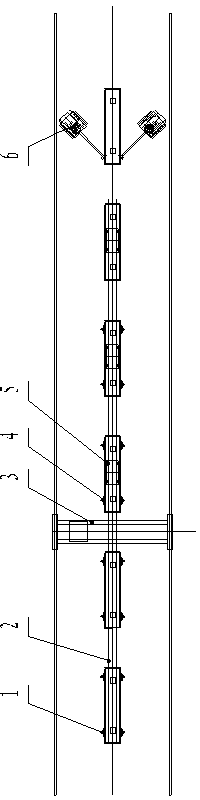

[0016] See attached Figure 1-2 , the present invention relates to a scrapped large-scale automobile dismantling assembly line, the assembly line is provided with a dismantling station 1, a waiting rotation station and a hydraulic dismantling machine 6 in sequence, there are multiple dismantling stations 1, and the The dismantling station is provided with a lift 4, and the bottom of the lift 4 is provided with moving wheels; the trolley track 2 is arranged at a symmetrical distribution position of the center line of the dismantling assembly line, and the lift 4 is arranged on the trolley track 2; the conveying trolley 5 is set on the trolley rail 2; the driving car 3 is set above the dismantling assembly line; hydraulic shears.

[0017] The specific process is as follows: firstly, the vehicle to be dismantled is towed to the first dismantling station of the dismantling assembly line, and a lift is installed on this station. Since the bottom of the lift is equipped with moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com