Production line device for disassembling scrapped cars

A scrapped car and assembly line technology, applied in the recycling of scrapped vehicles, motor vehicles, solid waste removal, etc., can solve the problems of irregular operation process, few professional and technical personnel of cars, and extensive dismantling methods, so as to reduce the occurrence of safety accidents efficiency, reduce the labor intensity of workers, and facilitate dismantling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

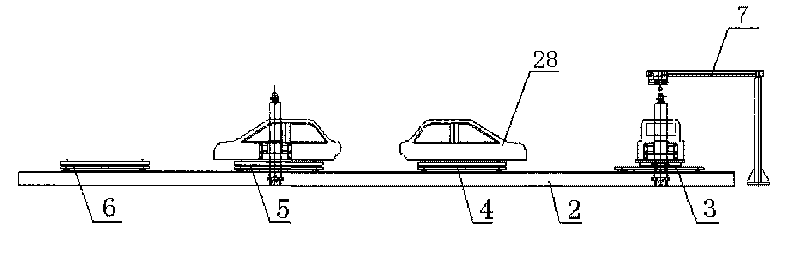

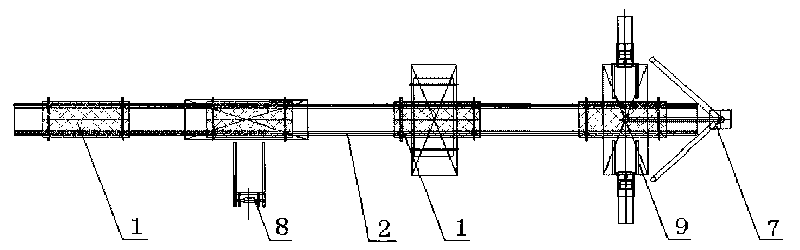

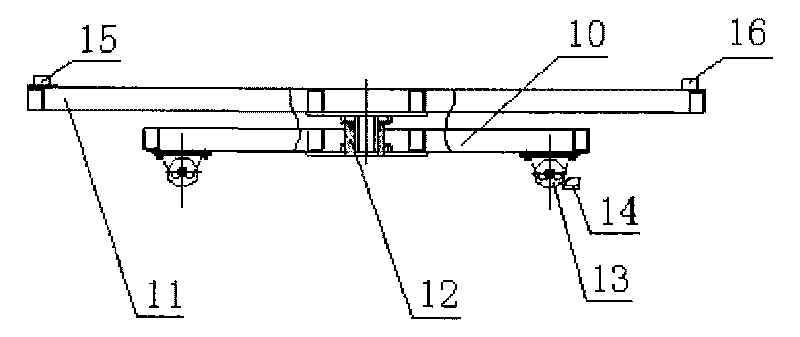

[0024] refer to Figure 1-Figure 6 , the scrapped automobile dismantling assembly line equipment of the present embodiment, it comprises conveying trolley 1, conveying guide rail 2, dismantling station, described conveying trolley 1 bottom is provided with guide wheel 13, and guide wheel 13 cooperates with conveying guide rail 2, can move along The conveying guide rail 2 moves. The dismantling station includes an engine dismantling station 3, a component dismantling station 4, a waste oil extraction station 5, and a hazardous waste dismantling station 6, and each of the above dismantling stations is arranged along the conveying guide rail 2 . The conveying trolley 1 includes a conveying car body 10 and a rotating car body 11. A rotating device 12 is arranged between the rotating car body 11 and the conveying car body 10. A thrust bearing is arranged in the rotating device, and the rotating car body 11 can rotate around The device rotates 360°. The rotating car body 11 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com