Disassembling system for ex-service passenger vehicle

A passenger car and body technology, applied in the field of decommissioned passenger car dismantling system, can solve the problems of destructive parts, weak environmental protection measures, low dismantling efficiency, etc., to achieve no secondary pollution and strong professional pertinence , to ensure the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

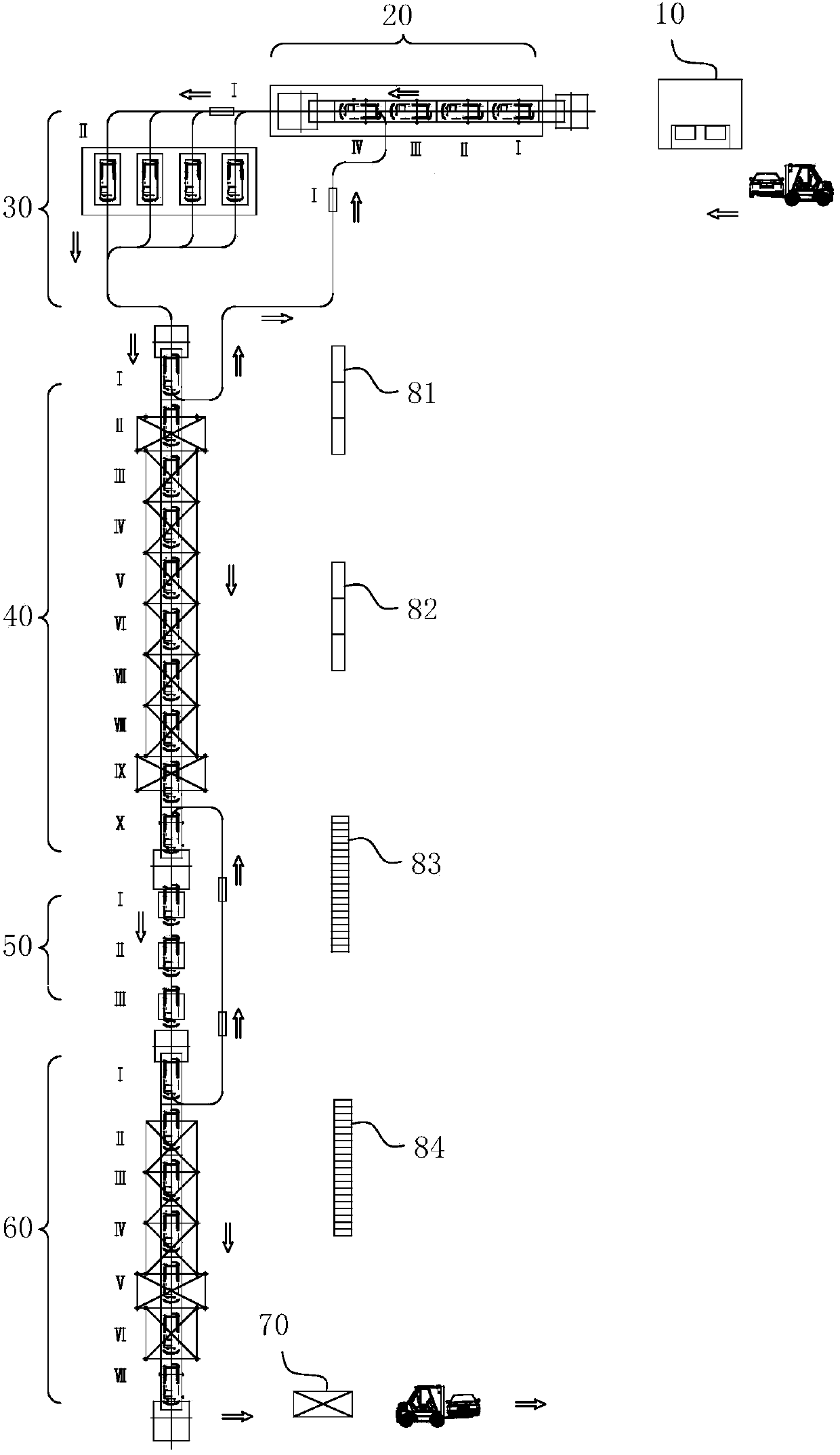

[0027] For ease of understanding, combined here figure 1 The concrete working process of the present invention is described as follows:

[0028] The high-efficiency and fine dismantling system for decommissioned passenger cars of the present invention is composed of a main dismantling line system and an auxiliary dismantling line system, and is specifically implemented through the following steps:

[0029] 1. Main dismantling line system

[0030] 1. The decommissioned passenger cars firstly carry out informatization registration, entry, photographing, inspection and other operations in the informatization room (that is, the informatization entry line 10 ), and the decommissioned passenger cars enter the environmental protection pretreatment line 20 after completion.

[0031] 2. The environmental protection pretreatment line 20 is equipped with 4 dismantling stations: after the vehicle is transported out of the information input line 10 and put on the line at the environmental...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com