Patents

Literature

43results about How to "Realization of secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic garbage and sludge mixed solid fuel and preparation method thereof

InactiveCN101215488AEasy to makeReduce processing costsSolid fuelsWaste based fuelFossil fuelPetroleum

The invention discloses solid fuel which is mixed by organic waste and sludge and a process for preparation. The solid fuel comprises the organic waste: 25%-55%, the sludge: 20%-50%, coal powder: 20%-50%, combustion improver: 0.15%-0.25% and desulfurization dechlorinating agent 0.5%-2%. The process for preparation comprises three stages of raw material preparation, molding and consolidation. The invention is tested by the solid fuel mechanical strength, burning characteristics, pollution control and the like. The solid fuel which is mixed by the organic waste and the sludge and prepared by the manufacturing process of the invention is comparatively ideal clean fuel with higher mechanical strength and can satisfy long-distance transportation with the falling strength more than 99%, the invention is the solid fuel with strong mechanical strength, good water resistance, excellent combustion characteristics, strong thermal stability and non pollution and can be extended to be applied in civilian uses and industrial sectors. The invention can also save a great amount of non-renewable fossil fuels such as petroleum, coal and the like with good social and environmental benefits.

Owner:TIANJIN URBAN CONSTR COLLEGE

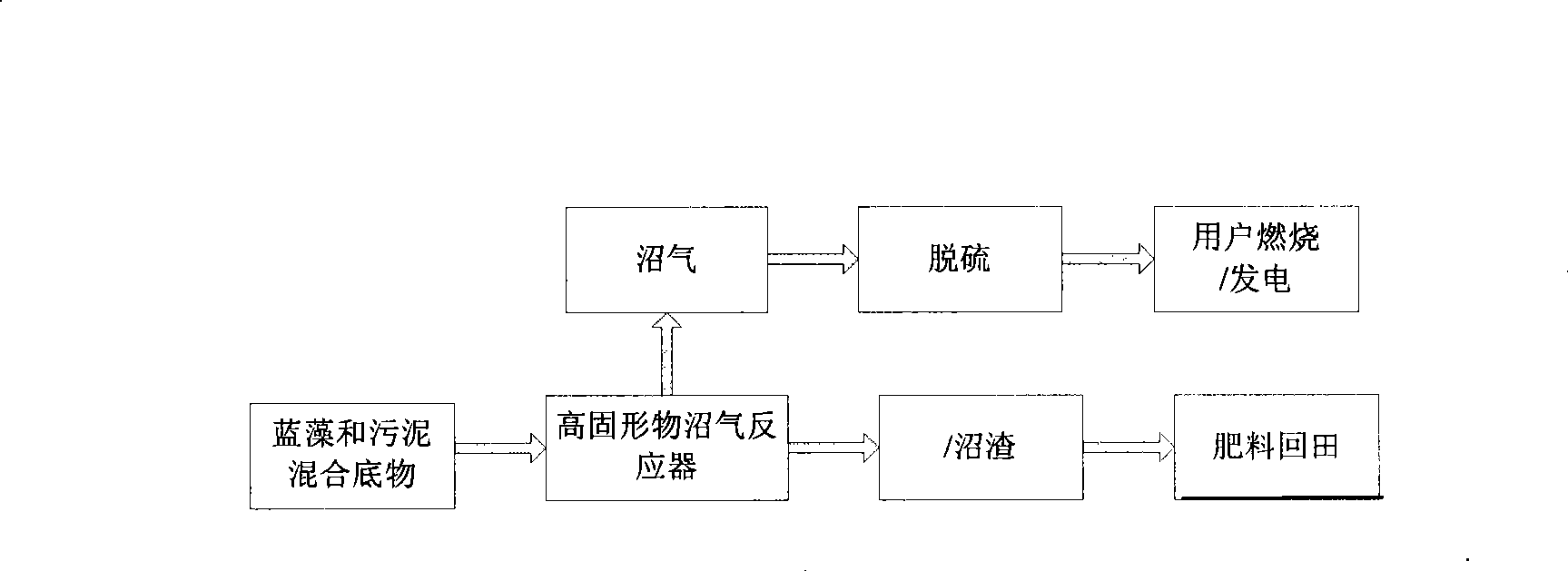

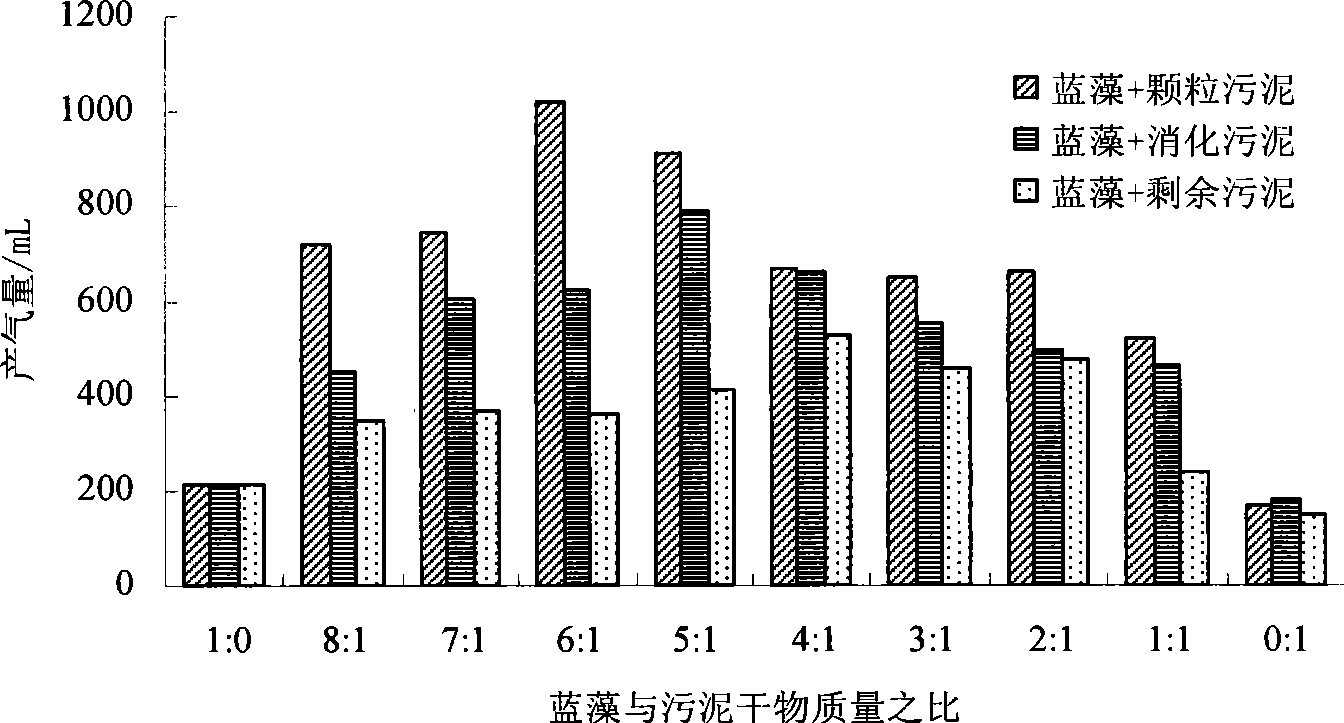

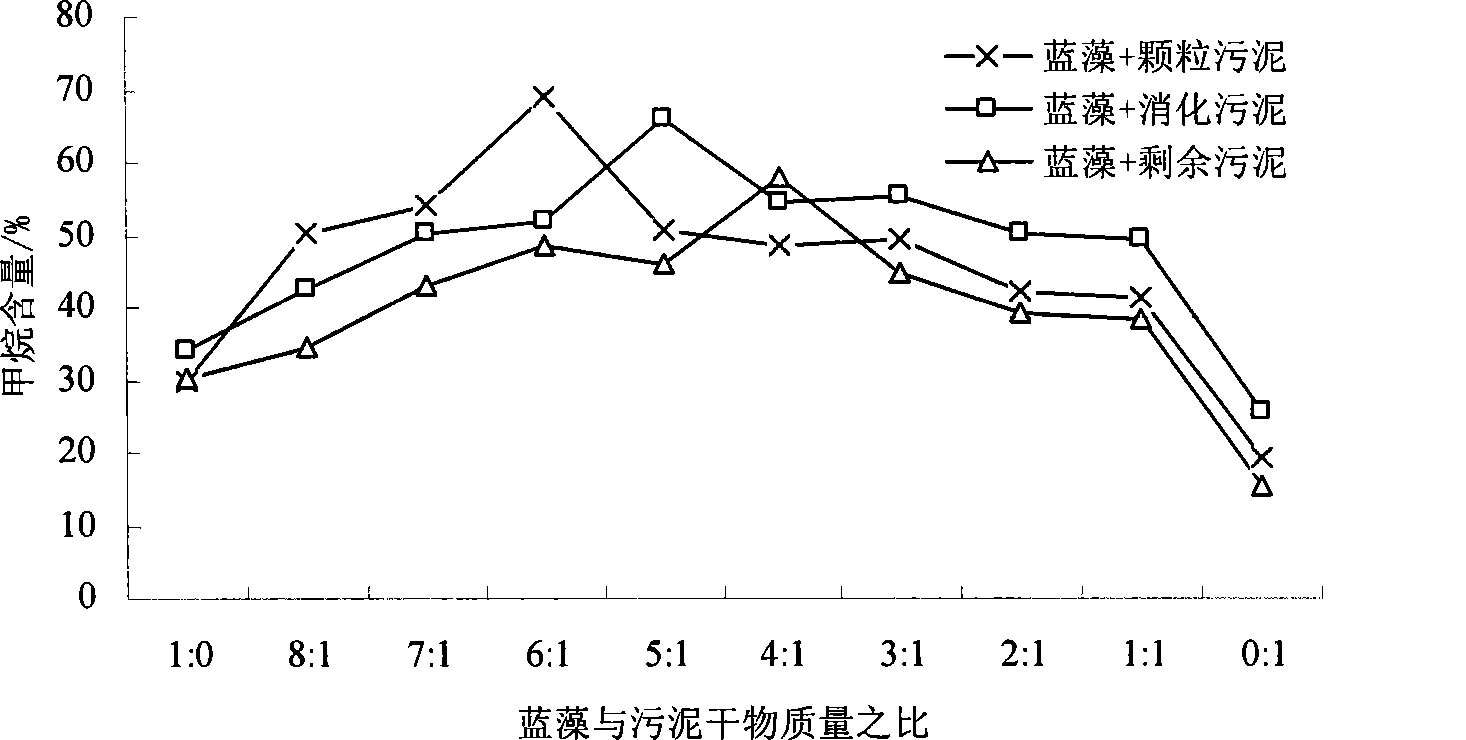

Method for producing marsh gas through mixed anaerobic fermentation of blue algae and sludge

InactiveCN101418316AReduce energy consumptionReduce pretreatment costsBio-organic fraction processingClimate change adaptationCombustionMunicipal sewage

The invention provides a method for producing biogas by the anaerobic fermentation of mixed blue algae and sludge, which belongs to the technical field of environmental protection purification and waste resource treatment. In the method, the blue algae and the sludge are mixed for the anaerobic fermentation to produce the biogas, and the whole process is completed in an anaerobic reactor; the blue algae and the sludge are mixed in the rector, N2 is introduced to form the anaerobic state, and the blue algae and the sludge are fermented at a temperature of between 35 and 37 DEG C; and in the rector, the blue algae is discontinuously and periodically added, the degradation condition of the material is observed, at the same time, the organic matter concentration of the discharged material and the concentrations of CH4 and CO2 in gas generated from fermentation are measured until the reactor is stably operated. The biogas generated is subjected to desulphurization treatment and supplied to users for combustion or collected for power generation; and the dregs generated are used as a fertilizer for farmlands. The method for producing the biogas by the anaerobic fermentation of the mixed blue algae and the municipal sludge has the advantages of having the effect of answering multiple purposes, thoroughly eliminating algae toxins, combining the blue algae utilization and the treatment of the sludge from a municipal sewage plant, and solving organic pollution problems in both the rural and urban areas.

Owner:JIANGNAN UNIV

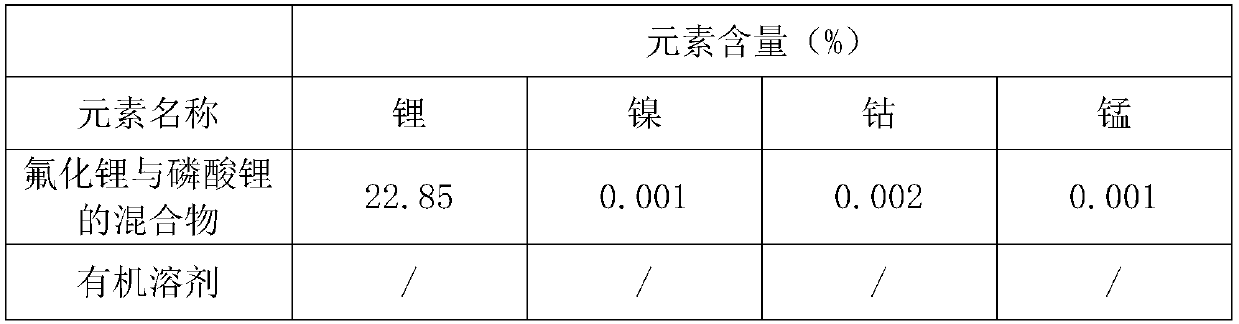

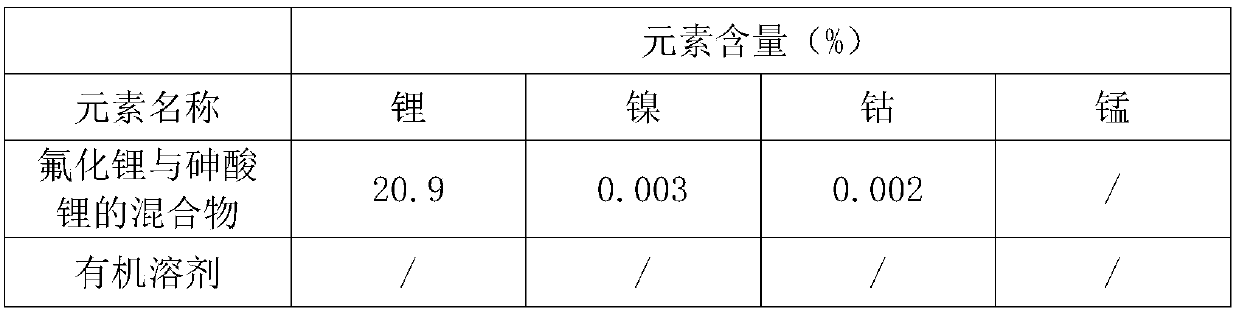

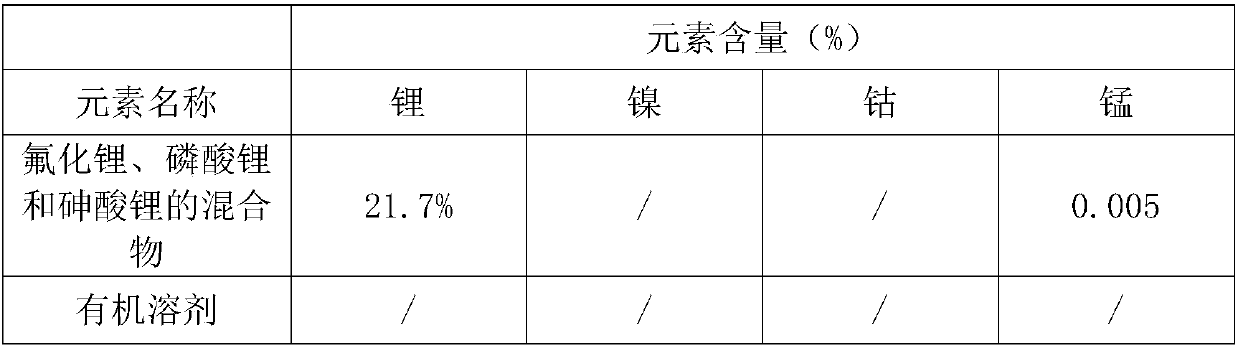

Waste lithium ion battery electrolyte solution recovery treatment method

ActiveCN109585963AAvoid secondary pollutionAchieve recyclingWaste accumulators reclaimingBattery recyclingOrganic solventLithium carbonate

The invention provides a waste lithium ion battery electrolyte solution recovery treatment method comprising freezing a waste lithium ion battery in liquid nitrogen; taking out the waste lithium ion battery and pulverizing the waste lithium ion battery by a low-temperature pulverizer to obtain a pulverized mixture; fully immersing the pulverized mixture in a container filled with a saturated lithium carbonate solution for a certain period of time according to certain proportion; successively filtering a reaction product by a coarse sieve and a fine sieve to obtain an oversized product and a filtrate; and finally separating an organic solvent and a lithium carbonate solution from the filtrate in an oil-water separation device under the effect of gravity; and collecting the organic solvent from the upper liquid outlet of the oil-water separation device, and collecting the lithium carbonate solution from the lower liquid outlet of the oil-water separation device. The method of the invention is simple in process, separates the electrolyte, the organic solvent and other components of the battery from the electrolyte solution, and is small in pollution and high in safety.

Owner:先进储能材料国家工程研究中心有限责任公司

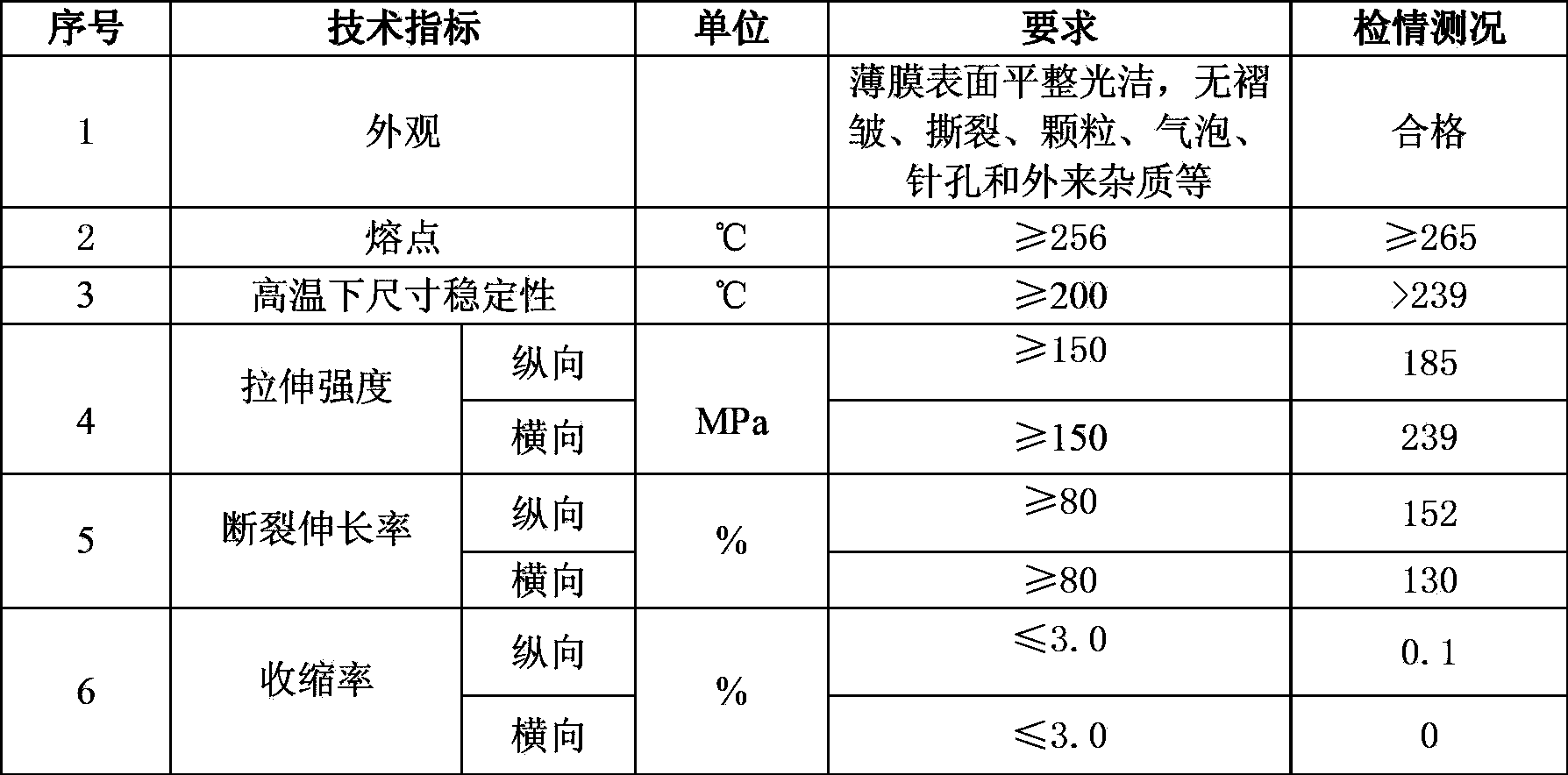

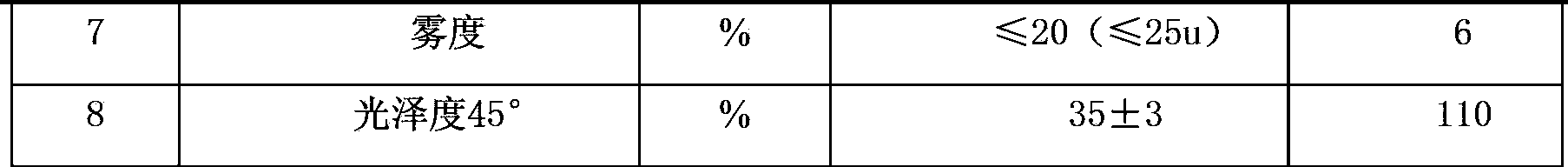

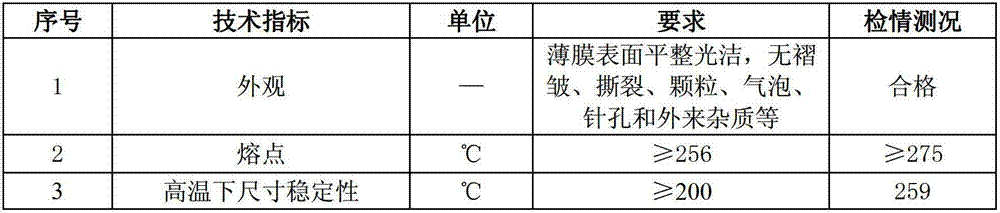

Ultrathin polyester film and manufacturing method thereof

An ultrathin polyester film is composed of a membrane-grade polyester slice and a polyester master batch slice, wherein the membrane-grade polyester slice accounts for 60% to 80% of the total weight of the ultrathin polyester film, and the polyester master batch slice accounts for 20% to 40% of the total weight of the ultrathin polyester film. The manufacturing method of the ultrathin polyester film is provided with corresponding special technological parameters in the processes of melt extrusion, roller cooling, longitudinal stretching, and horizontal stretching. The raw materials of the ultrathin polyester film contain a titanium homogeneous catalyst, so the ultrathin polyester film can be applied to the field of food package such as cooked food package, candy package, package for various kinds of foods, and the like, and is environment-friendly and nontoxic. Corresponding technological conditions are set in the production process of the polyester film product so as to achieve the product characteristics of high transparency, non-toxicity, no odor, high chemically-resistant performance, high temperature resistant performance, high corrosion resistant performance, good shielding performance on ultraviolet lights, and good oxygen gas obstructing performance.

Owner:TIANJIN SHIQI TECH DEV

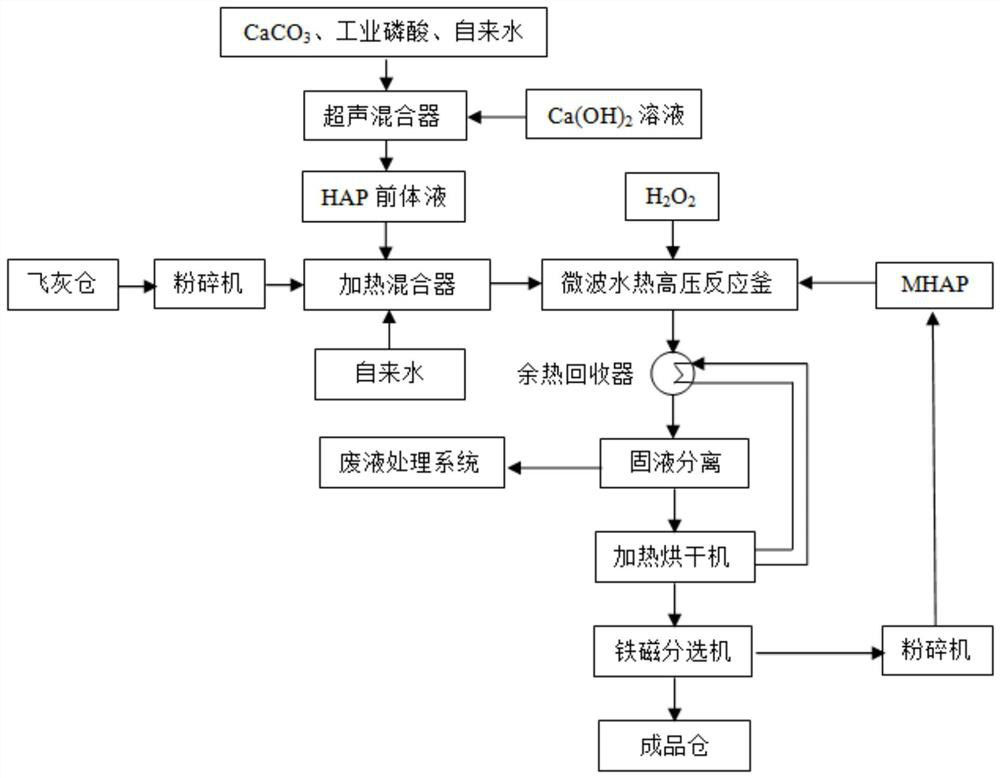

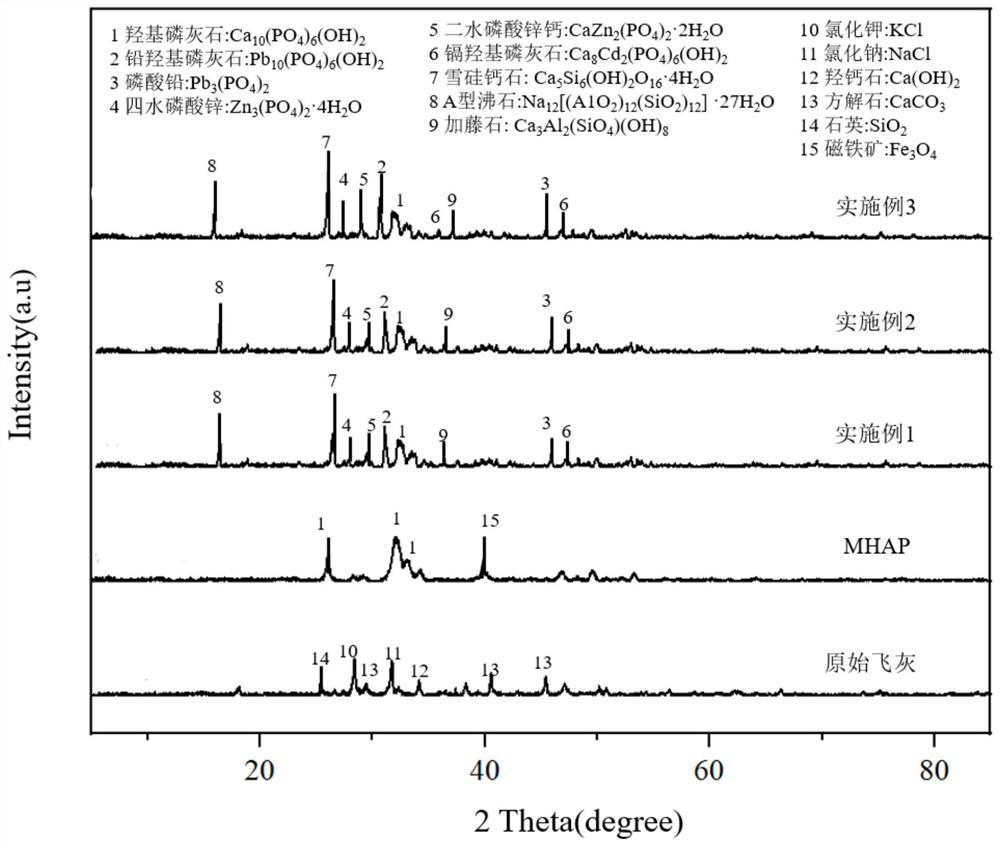

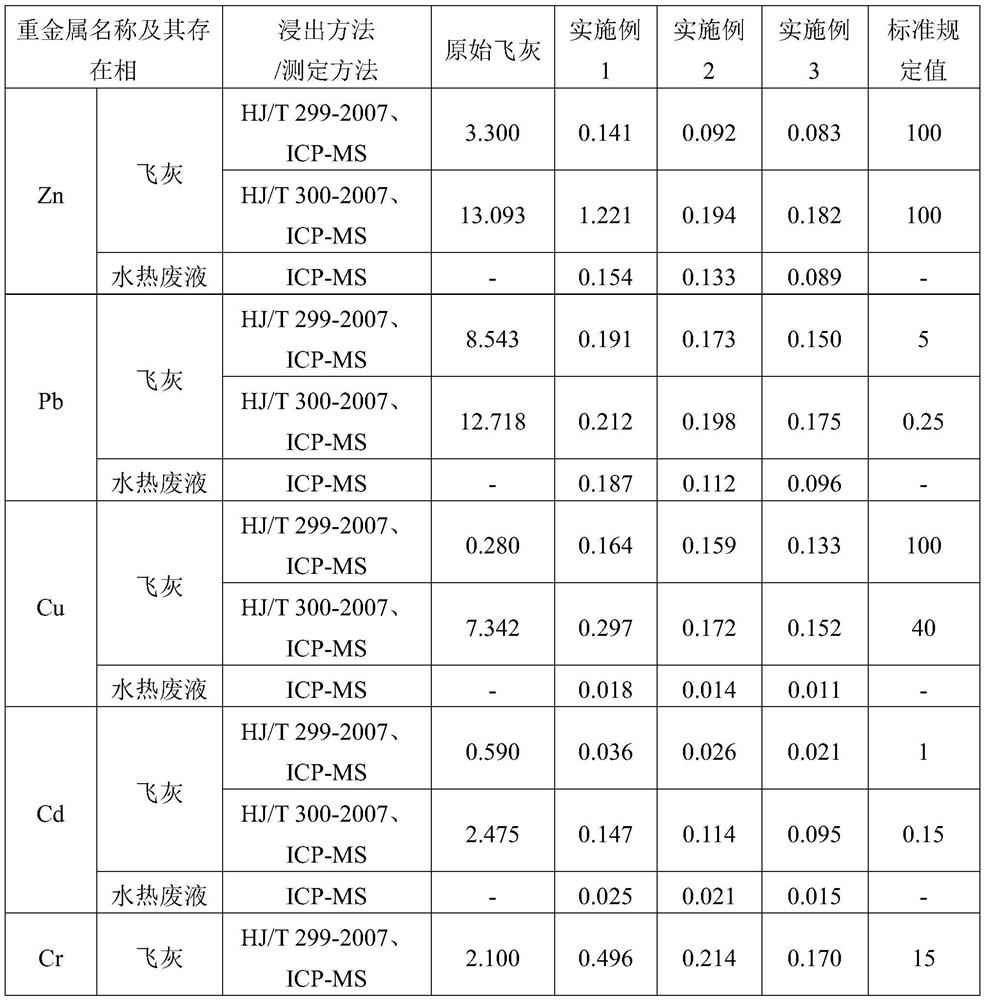

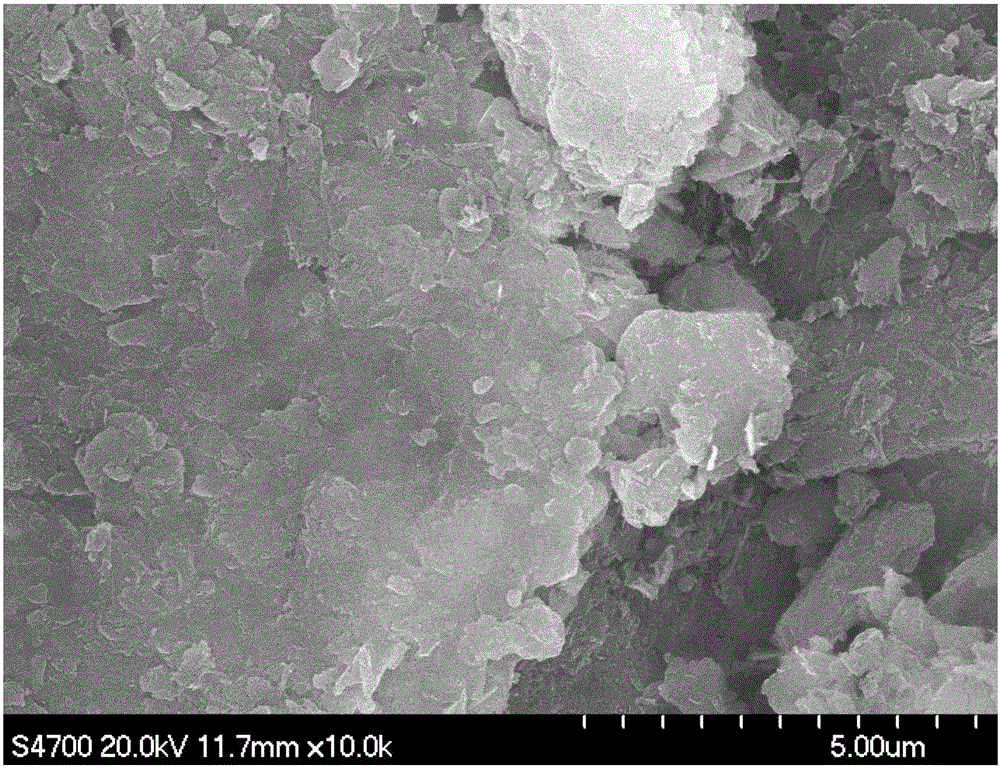

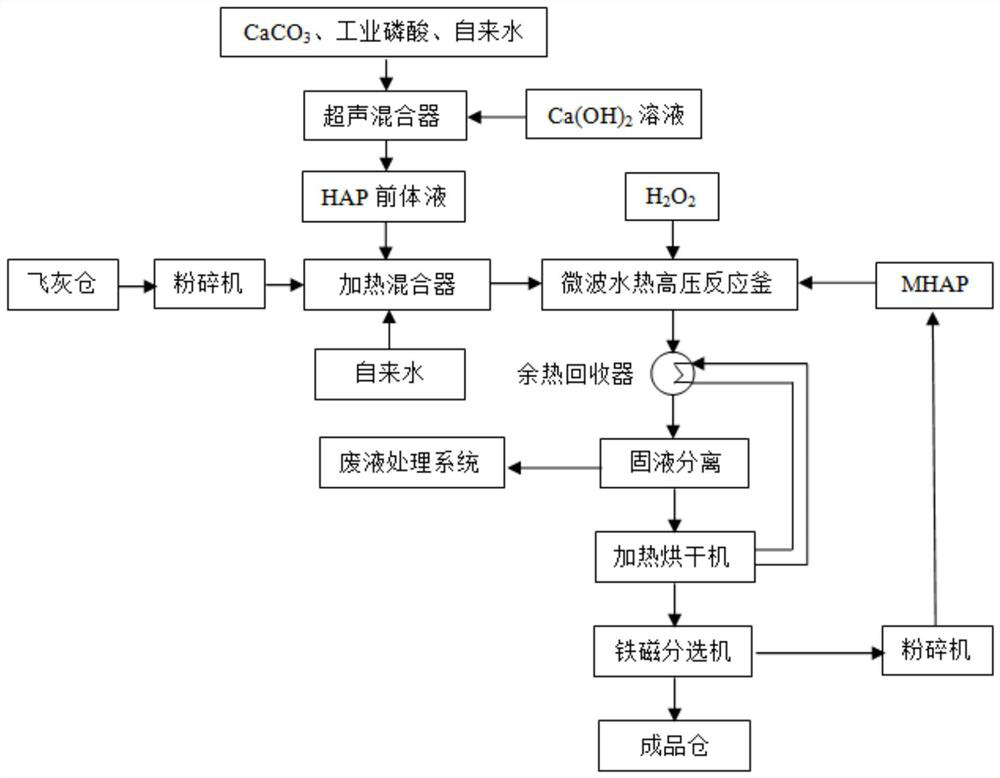

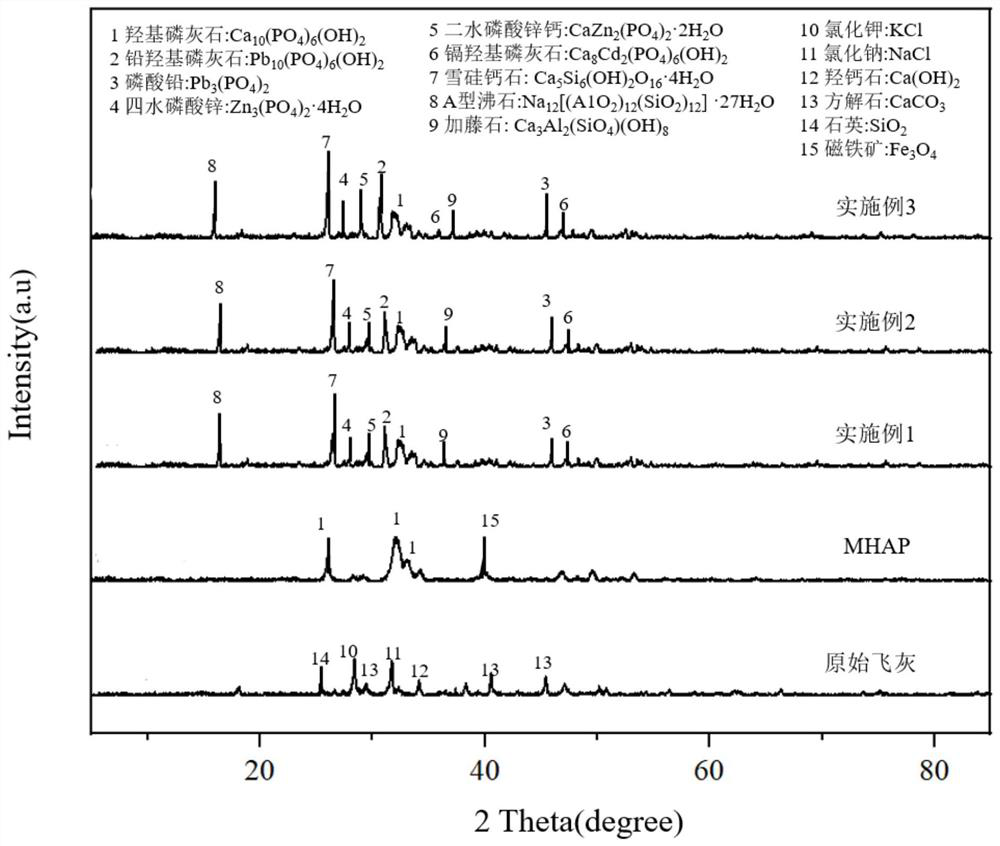

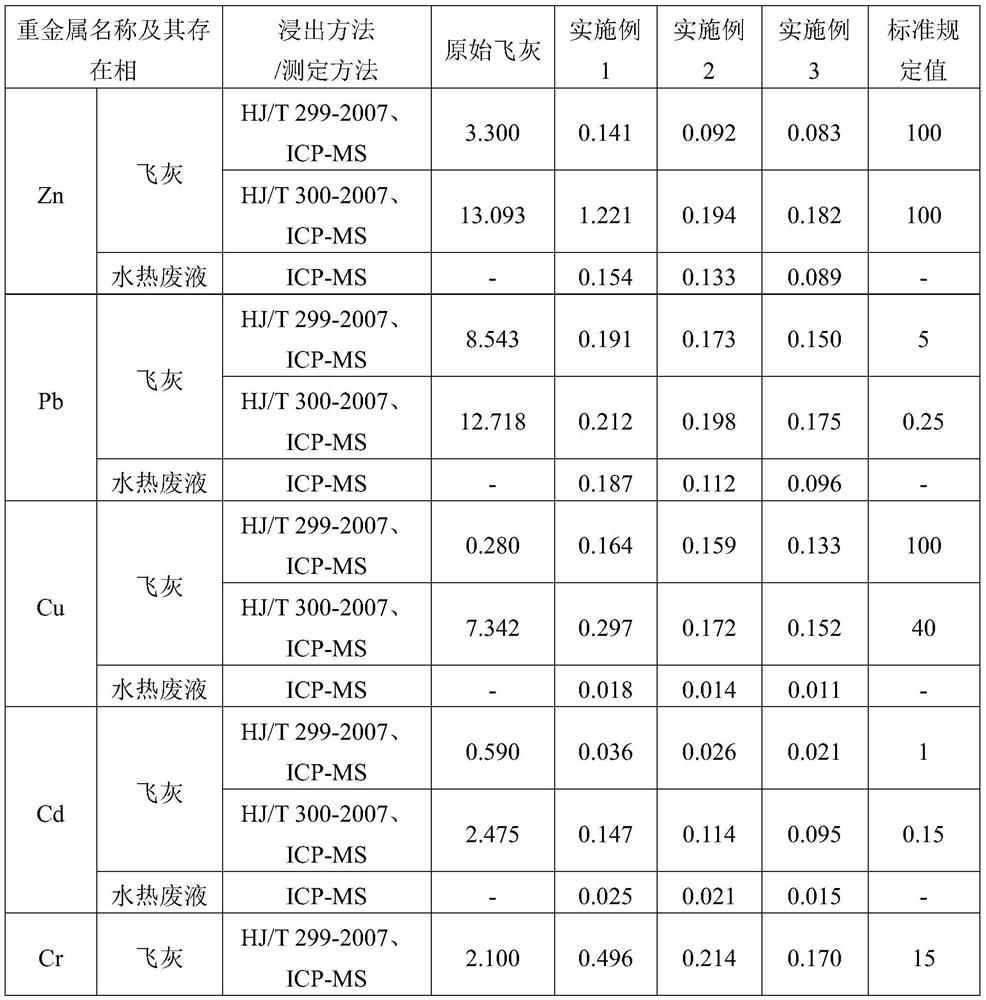

Method for harmless treatment of waste incineration fly ash through hydrothermal technology

ActiveCN111672876AStable and efficientImprove adsorption capacitySolid waste disposalTransportation and packagingEngineeringPolyaromatic hydrocarbon

The invention discloses a method for harmless treatment of waste incineration fly ash through a hydrothermal technology. The method comprises the following steps of (1) adding a hydroxyapatite precursor liquid into fly ash, and then performing first-step hydrothermal reaction under normal pressure at 40 to 50 DEG C to stabilize heavy metals in the fly ash; and (2) adding magnetic hydroxyapatite powder and hydrogen peroxide into a mixture obtained by the reaction of the step (1), and then performing second-step microwave hydrothermal reaction under a high pressure at 20 to 150 DEG C to furtherstabilize the heavy metals in the fly ash and degrade polyaromatic hydrocarbons. According to the method, stabilization of the heavy metals and degradation and detoxification of the polyaromatic hydrocarbons in the waste incineration fly ash can be realized efficiently and synchronously; the leaching toxicity of the heavy metals is lower than identification standards for hazardous wastes and can meet domestic waste landfill pollution control standards; the heavy metals are actually stabilized in the fly ash rather than being transferred to a hydrothermal waste liquid on a large scale; the toxic equivalent degradation rate of sixteen polyaromatic hydrocarbons is up to 95.06 percent; and secondary pollution is prevented.

Owner:CHONGQING UNIV

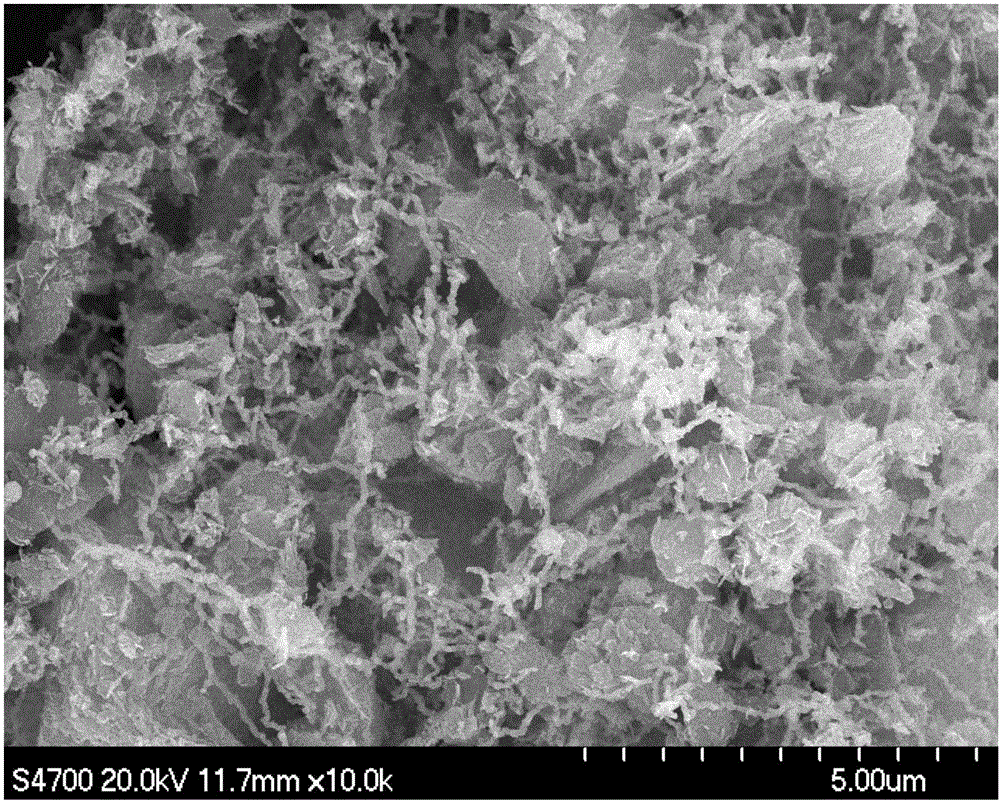

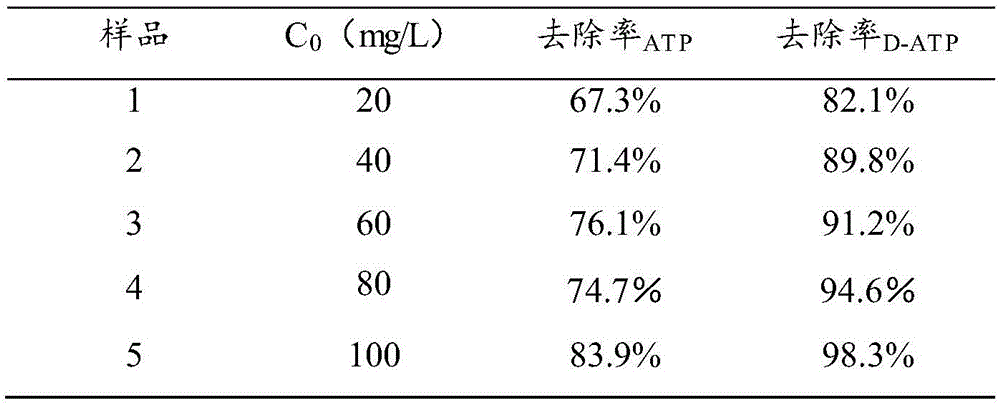

Preparation method for quaternary ammonium salt modified attapulgite for heavy metal adsorption

InactiveCN105854787AGood dispersionLarge adsorption pore sizeOther chemical processesWater contaminantsAlcoholQuaternary ammonium cation

The invention relates to a preparation method for quaternary ammonium salt modified attapulgite for heavy metal adsorption. The attapulgite is taken as the core of the material and is grafted with the quaternary ammonium salt on the surface; in an absolute ethyl alcohol solution, the quaternary ammonium salt modified attapulgite is prepared through ultrasonic wave; the prepared quaternary ammonium salt modified attapulgite has better dispersibility and adsorbability and larger superficial area; more functional groups, such as amino, hydroxyl, are grafted; the functional groups are easily combined with the attapulgite and metal ions; the pollutants can be long-term efficiently controlled; when concentration of Pb<2+> is 100mg / L, the removal rate reaches 98.3%; when concentration of Cd<2+> is 100mg / L, the removal rate reaches 99.4%. The preparation method has the advantages of simple technique, no secondary pollution and excellent market potential.

Owner:BEIJING UNIV OF CHEM TECH

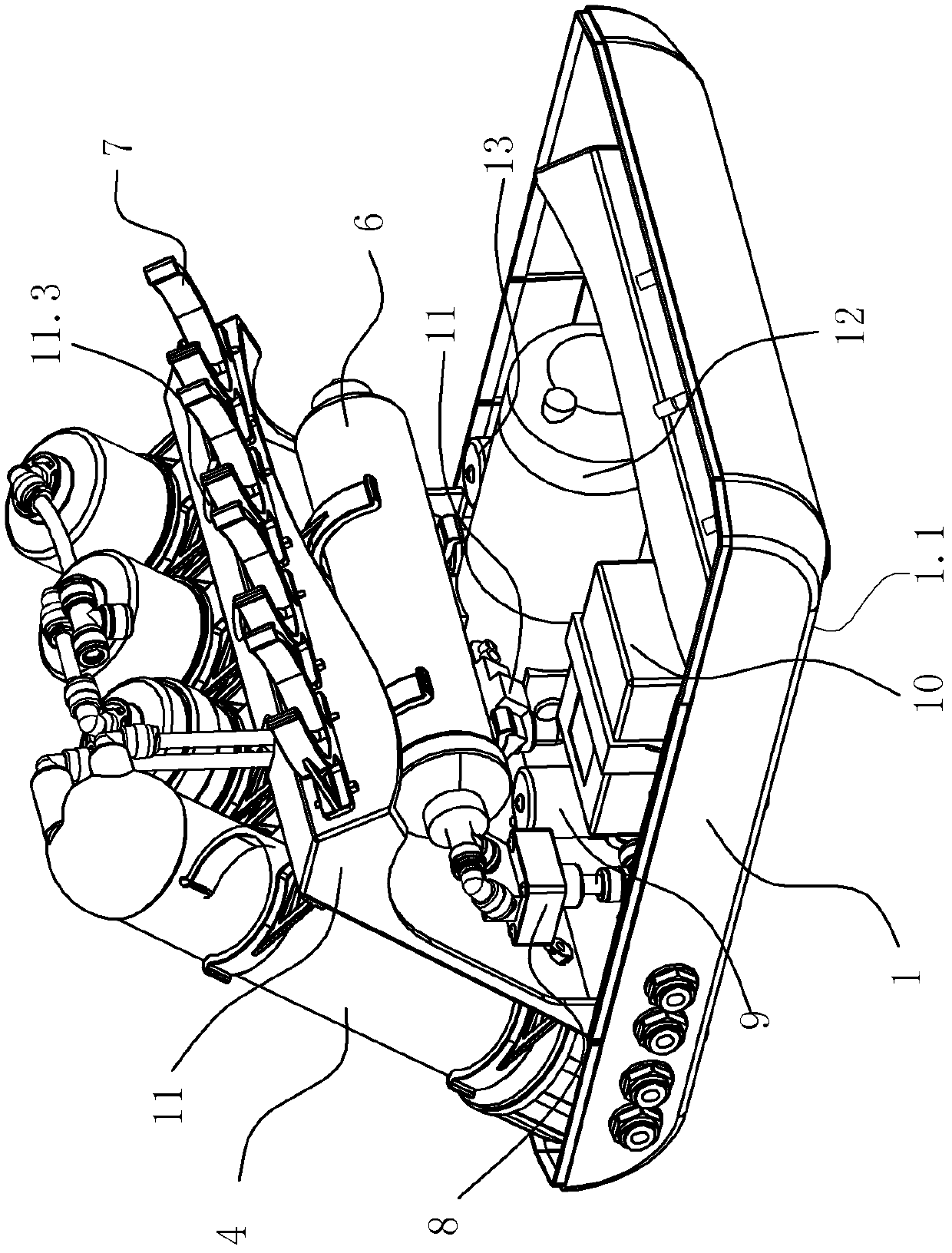

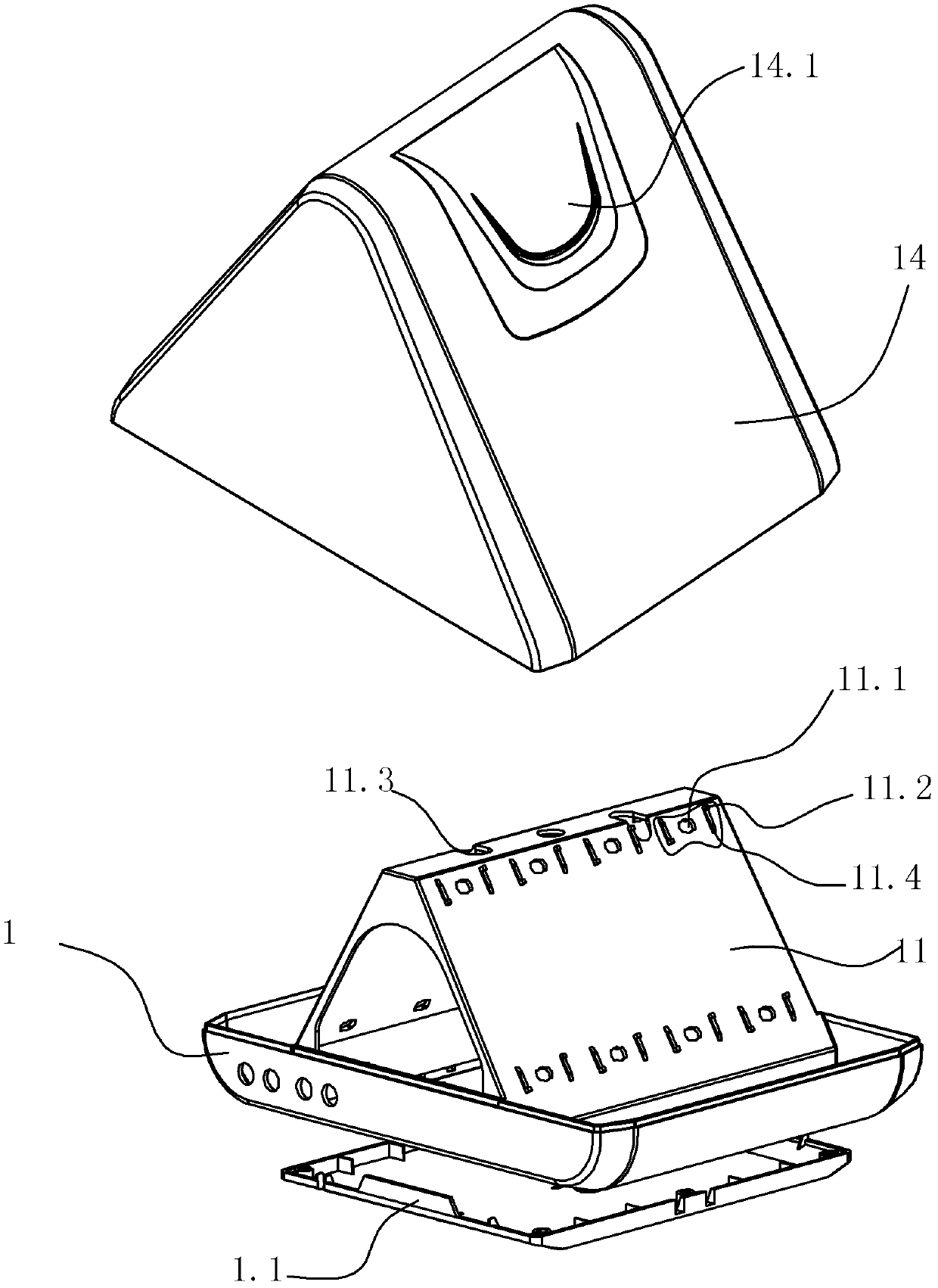

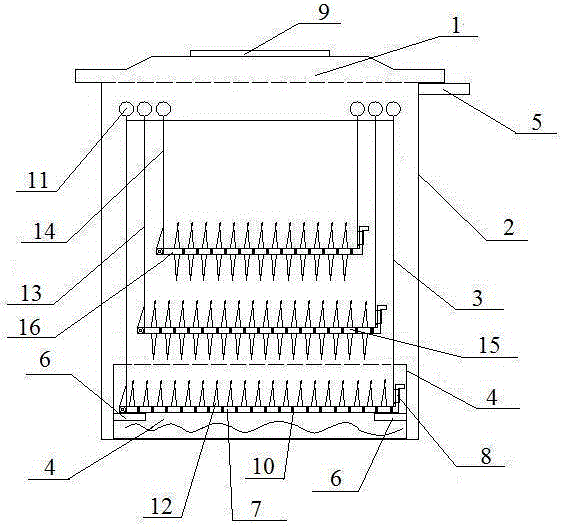

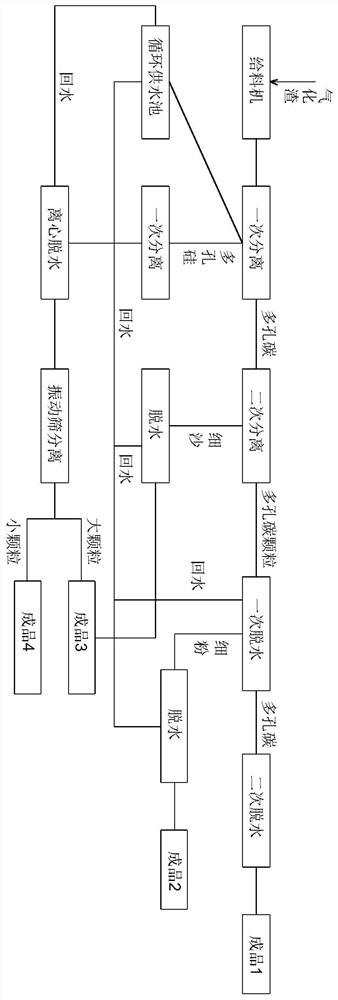

Water purification machine

ActiveCN103288228AReduce volumeIncrease in sizeMultistage water/sewage treatmentControl systemFiltration

The invention relates to a water purification machine, comprising a machine base, and a coarse filtration system and a fine filtration system which are mounted on the machine base. The water purification machine is characterized in that a mounting base with a triangular cross section is arranged on the machine base; a pedestal is arranged at the bottom of the machine base; an electrical element for controlling the systems is mounted in an accommodating cavity between the pedestal and the mounting base; the coarse filtration system is provided with two groups of filter elements connected in parallel; the fine filtration system is provided with two groups of reverse osmosis (RO) membrane assemblies connected in parallel; and the two groups of filter elements and the two groups of RO membrane assemblies are mounted on the inclined surfaces at the two sides of the mounting base respectively. The water purification machine is reasonable and compact in structure, convenient to assemble and low in cost; the water output quantity is large; and the water quality is fresh.

Owner:ZHEJIANG RUNXIN ELECTRIC APPLIANCE CO LTD

Electroslag remelting solid slag arc striking agent and arcing method thereof

The invention discloses an electroslag remelting solid slag arc striking agent and an arcing method thereof. The electroslag remelting solid slag arc striking agent consists of the following components in percentages by mass: 3-5% of pre-melted slag, 0.3-0.5% of aluminum particles and the balance of scrap iron. The scrap iron is used as the main raw material of the solid slag arc striking agent, the scrap iron which is machining waste is recycled, the cost is low, secondary pollution does not exist, and the waste is reused; and moreover, resources are saved, the cost is greatly saved, and possibility of environmental pollution is eliminated. The method has the characteristics of simplicity in operation, stable process, high success rate and the like.

Owner:HEBEI IRON AND STEEL

Preparation method of alpha-FeOOH/GAC catalyst and application thereof in degradation of nitrobenzene wastewater in supergravity field

ActiveCN111686731AIncrease spawn rateIncrease oxidation rateWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

Owner:ZHONGBEI UNIV

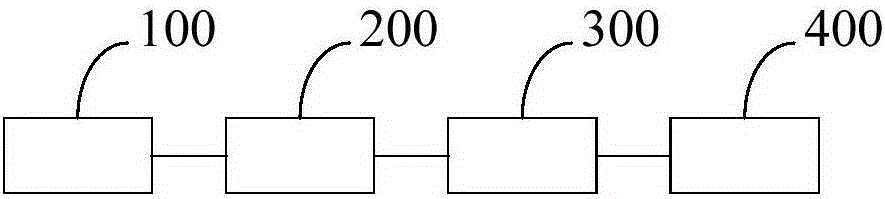

Power generation system using household garbage and power generation method thereof

InactiveCN105327930ARealize comprehensive utilizationSolve pollutionSolid waste disposalIncinerator apparatusCombustion chamberWater vapor

The invention discloses a power generation system and a power generation method. The power generation system generates power through using household garbage, and comprises a pyrolysis furnace, a combustion chamber, a waste heat boiler and a power generation device, wherein the pyrolysis furnace is used for pyrolyzing the household garbage, so as to obtain pyrolytic oil gas and pyrolytic carbon; the pyrolytic oil gas comprises pyrolytic oil and pyrolytic gas; the combustion chamber is connected with the pyrolysis furnace, and is used for performing direct combustion treatment on the pyrolytic oil gas, so as to obtain smoke; the waste heat boiler is connected with the combustion chamber, and performs heat exchange treatment through using the water vapor smoke and water in the waste heat boiler, so as to obtain superheated steam and cooled smoke; and the power generation device is connected with the waste heat boiler, and generates power through using the superheated steam. The power generation system provided by the embodiment of the invention has the advantages of simple structure, high thermal efficiency and low energy consumption.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

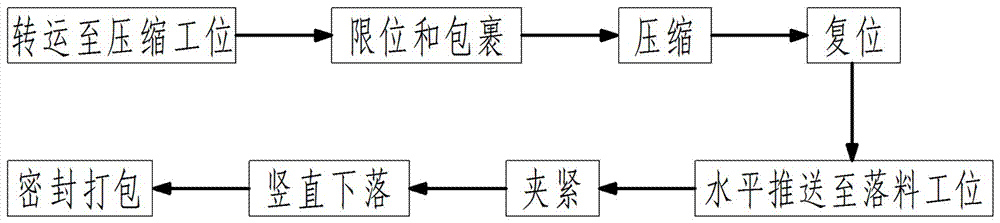

Method and equipment for volume reduction treatment of low-radioactivity waste circular filters

ActiveCN106898405APrevent proliferationGuaranteed cleanlinessRadioactive decontaminationAutomationWaste management

The invention discloses a method and equipment for volume reduction treatment of low-radioactivity waste circular filters. The method includes: transferring a to-be-compressed waste circular filter to a compression station, and adopting a limiting oil cylinder for driving a limiting barrel to vertically move downwards so as to limit and wrap the to-be-compressed waste circular filter in an inner cavity of the limiting barrel; adopting a main cylinder of a hydraulic press for driving a compression plate to press downwards vertically to downwardly compress the waste circular filter into a cake shape; pushing to a discharging station at the bottom surface of a cavity of a receiving glove box by a pushing device; after a clamping device clamps, allowing an isolation device to horizontally move away from a circular discharging hole, so that the waste circular filter is vertically discharged into a lining seal bag in a cavity of a waste bucket; after the cavity of the waste bucket is full, performing sealing, packaging, transferring and storing. The compression volume reduction ratio is high, storage volumes of the waste circular filters are greatly reduced, and aftertreatment cost is reduced. In addition, the method and the equipment have advantages of high automation degree, high efficiency, safety, energy saving, environmental friendliness and the like.

Owner:HENAN HEJING CLEANING TECH

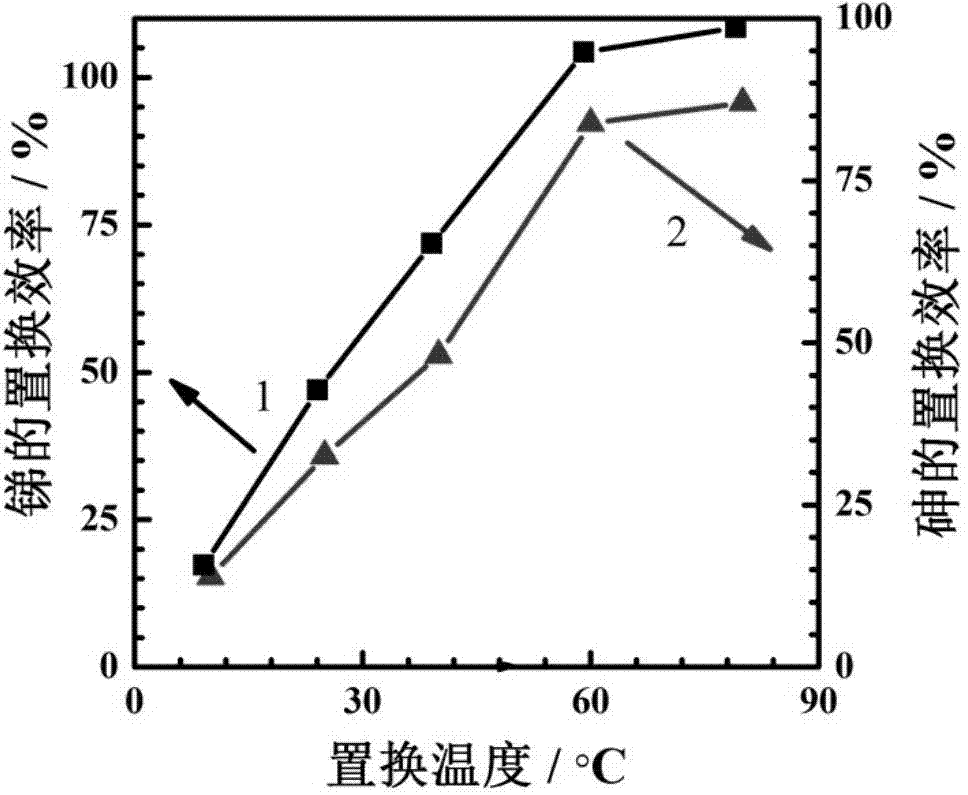

Method for removing and recovering arsenic and antimony in water body by replacement of copper powder

ActiveCN104496000ASimple preparation processEasy to operateWaste water treatment from metallurgical processWater/sewage treatment by flocculation/precipitationNitrogen gasAntimony

The invention provides a method for removing and recovering arsenic and antimony in a water body by replacement of copper powder. The method comprises the following steps: (1) adjusting the pH of arsenic and antimony-containing wastewater to 0-3 by using hydrochloric acid; under nitrogen protection, adding copper powder, closing a reactor and stirring at a speed of 100-600r / minute to react, wherein the reaction temperature is 10-80 DEG C and the replacement time is 10-120 minutes; in the arsenic and antimony-containing wastewater, the content of As(III) is 0.1-10g / L and the content of Sb(III) is 0.1-25g / L; the use level of the copper powder is 5-100g / L based on the volume of the wastewater by mass; and (2) after replacement, filtering the reaction system, recovering filter residues and crystals which are obtained by recrystallizing the filtrate quickly at a low temperature. The method provided by the invention is simple in process, free of secondary pollution and economical and environment-friendly, and reproducible utilization of resources is achieved.

Owner:ZHEJIANG UNIV OF TECH

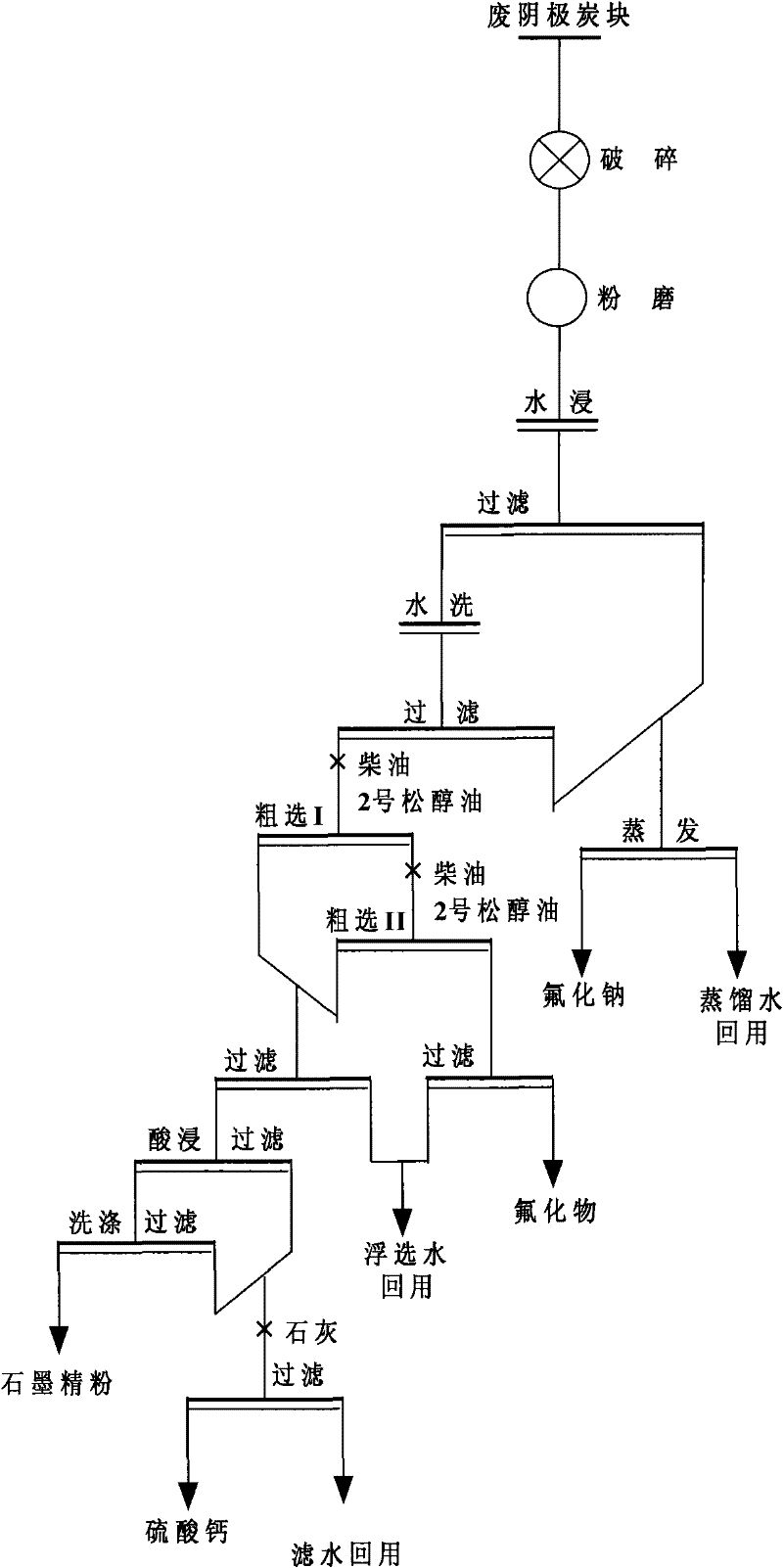

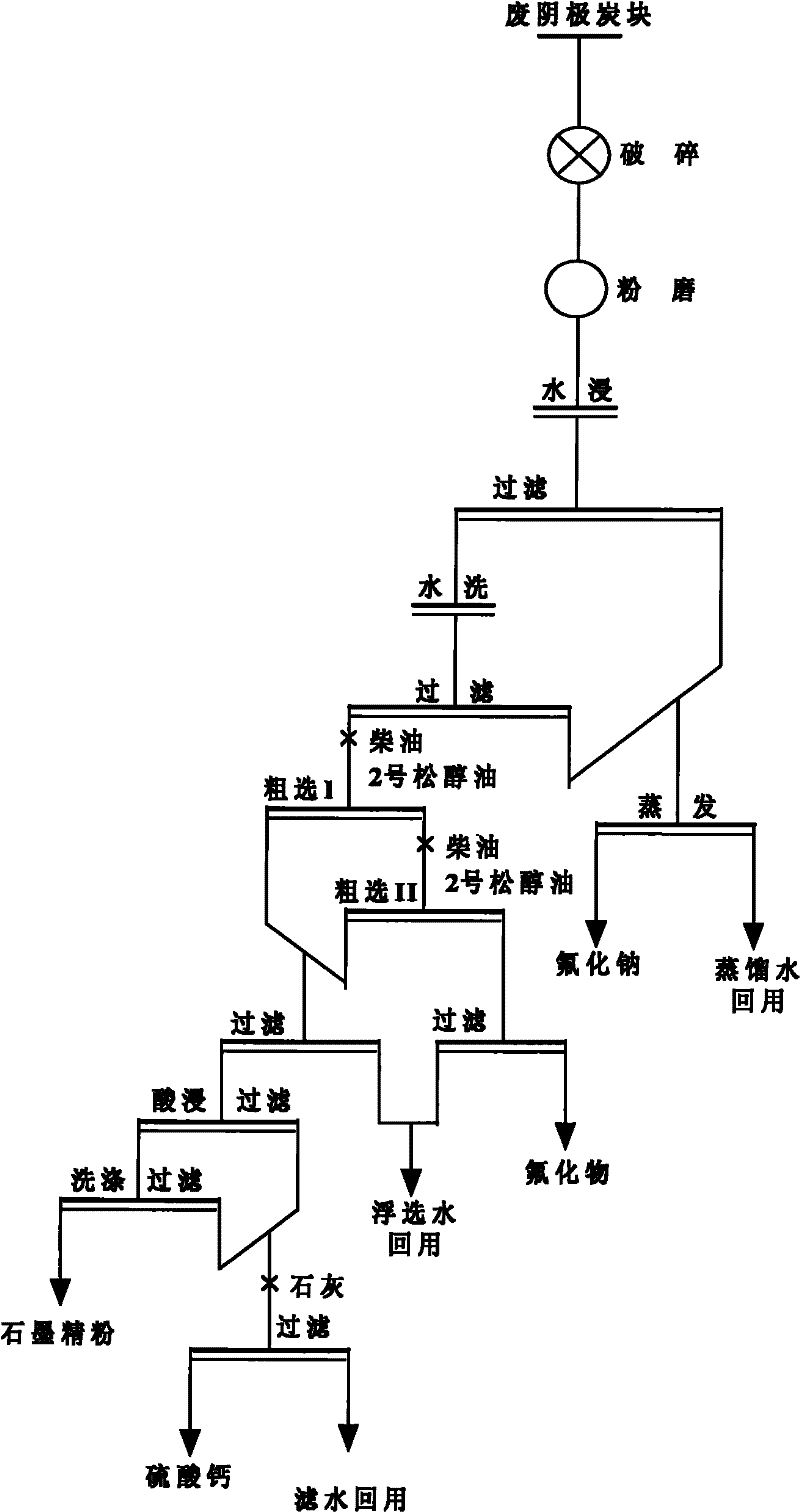

Method for recovering graphite from waste cathode carbon blocks in electrolytic aluminium production

The invention discloses a method for recovering graphite from waste cathode carbon blocks in electrolytic aluminium production, which mainly includes steps of breaking and grinding, water leaching, floatation and acid leaching. The carbon content of the finally obtained graphite powder is up to more than 80 percent, the recovery rate is up to more than 90 percent, and the graphite powder can be used as a material for the production of carbon material for aluminium electrolysis, alumina desulfurizer and the like; and the recovered graphite powder has high purity, high value in use and remarkable economic and social benefits. The purity of sodium fluoride as byproduct is up to more than 96 percent, and therefore the sodium fluoride can be sold as a product; and calcium sulfate as byproduct can replace natural gypsum to serve as retarder for the production of cement. The method has the advantages of simple technique, low production cost, no secondary pollution, stable and reliable product quality, high yield and continuous and mass production, and realizes the recycling of carbon and fluorin resources.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Preparation method of plant-fiber foamed cement based heat insulating material for buildings

The invention specifically relates to a preparation method of a plant-fiber foamed cement based heat insulating material for buildings. The preparation method comprises the following steps of: firstly, soaking plant fibers in dilute sulphuric acid with concentration being 0.1-0.2 mol / L for 50-80min, flushing until neutral, adding rosin and gelatin to the plant fibers in a mass ratio of plant fibers: rosin: gelatin being 1: (2-8): (2-10), regulating the pH value to 12-14, and then heating the solution to 85-90 DEG C, stirring for 120-150min, adding a fiber surface modifier after stopping heating, and then cooling to the room temperature, thus obtaining a fiber mixed solution; in use, stirring and foaming the fiber mixed solution in a stirrer having a rotating speed being 600 to 5000r / min for 2-4 min so as to obtain fiber foams; and then adding the fiber foams to cement and moulding, thus obtaining the plant-fiber foamed cement based heat insulating material. The plant-fiber foamed cement based material provided by the invention has the characteristics of excellent thermal insulation properties, low density, air shrinkage resistance, crack resistance and toughening, humidifying and the like.

Owner:WUHAN UNIV OF TECH

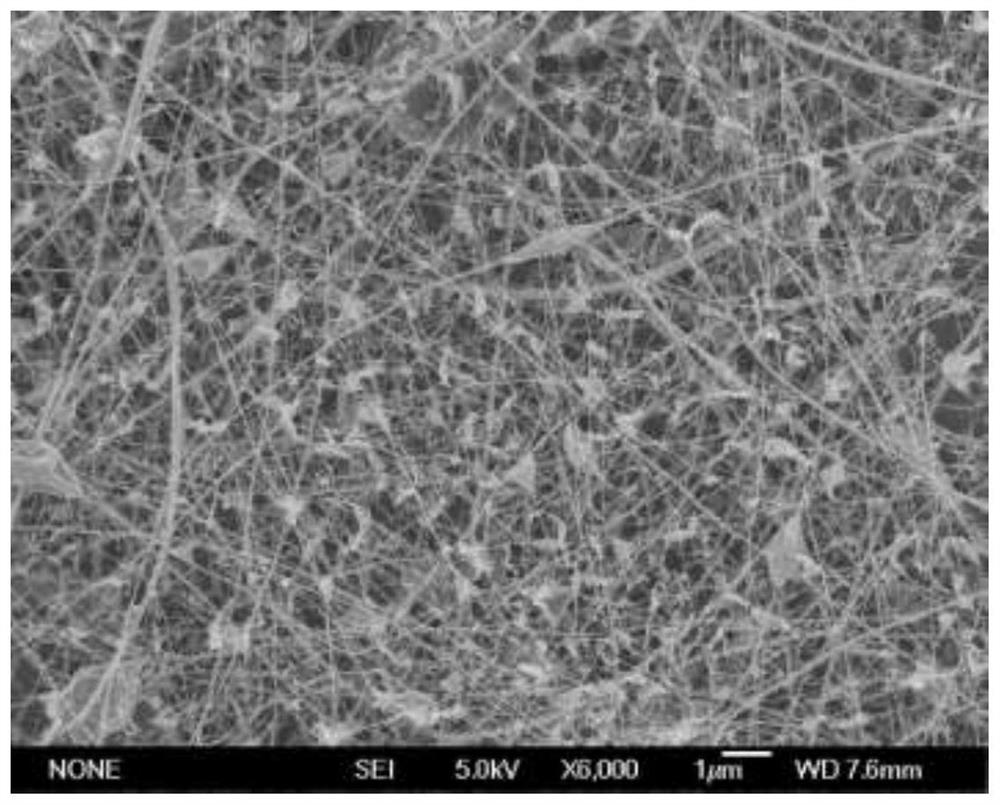

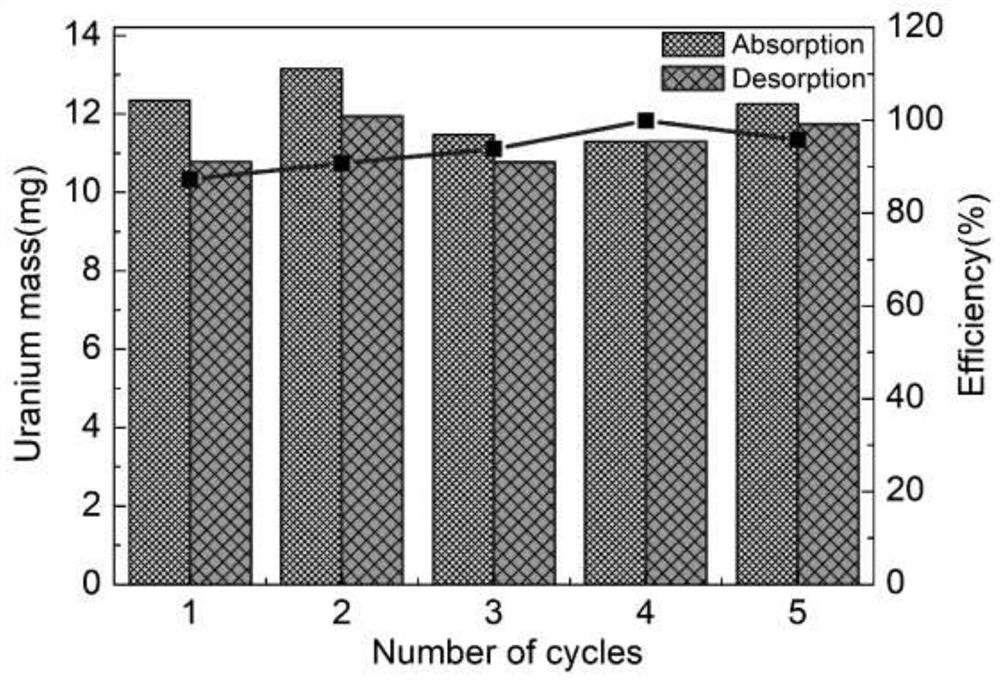

Preparation method of convenient and fast nanofiber-based wiping cloth for nuclear pollution equipment

PendingCN111648034AStable physical propertiesGood regeneration performanceCleaning using toolsConjugated synthetic polymer artificial filamentsSpinningNonwoven fabric

The invention relates to a preparation method of convenient and fast nanofiber-based wiping cloth for nuclear pollution equipment. According to the preparation method, water-soluble polymer is used asa raw material, nanofibers are prepared through an electrostatic spinning method, the wiping cloth is prepared on a base material, the wiping cloth can improve the adsorption amount of radioactive metal ions through surface modification, the regeneration performance of the wiping cloth is improved, and rapid and deep cleaning treatment of the surface of nuclear pollution or radioactive pollutionsolid is achieved. The specific preparation method of the wiping cloth comprises the following steps of dissolving the hydrophilic polymer serving as the raw material into a solution for later use; and the hydrophilic nanofibers are prepared in the solution through an electrostatic spinning technology and woven into the wiping cloth on the material with a non-woven fabric as a base. The surface ofthe wiping cloth is modified through functional groups, the adsorption amount of the radioactive metal ions of the wiping cloth is increased, the regeneration performance of the wiping cloth is improved, and the fast deep cleaning treatment on the nuclear pollution or radioactive pollution solid surface is realized.

Owner:LOGISTICS UNIV OF CAPF

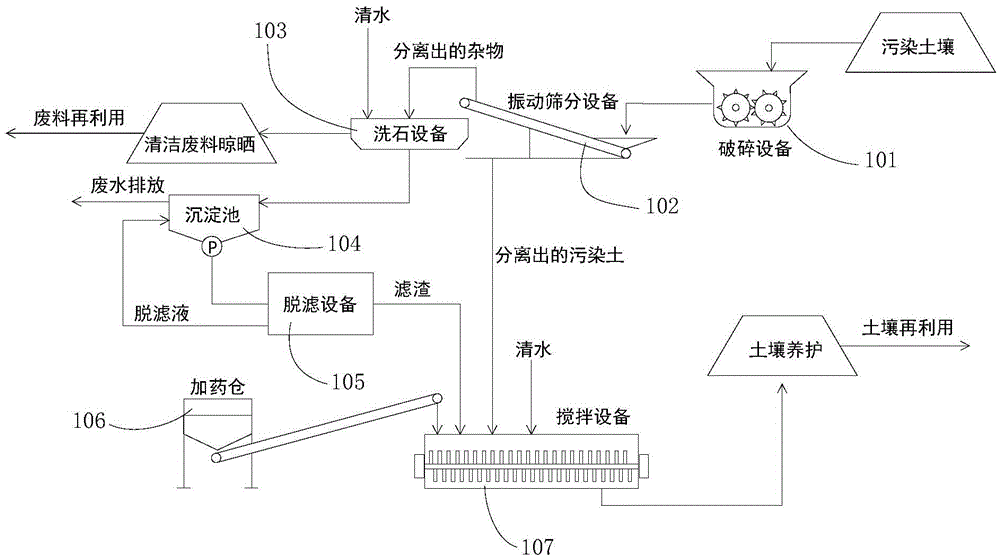

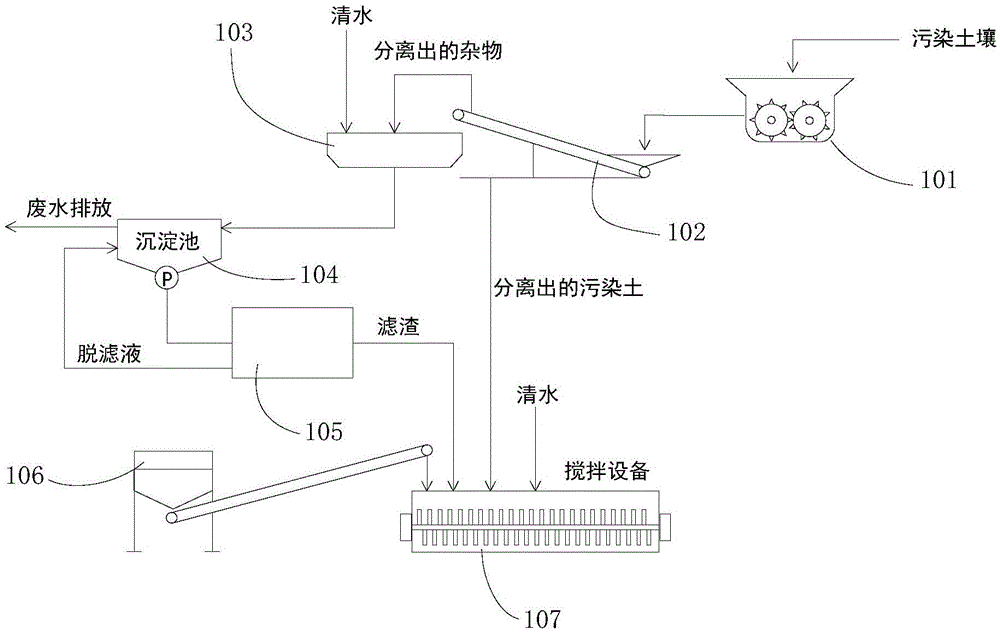

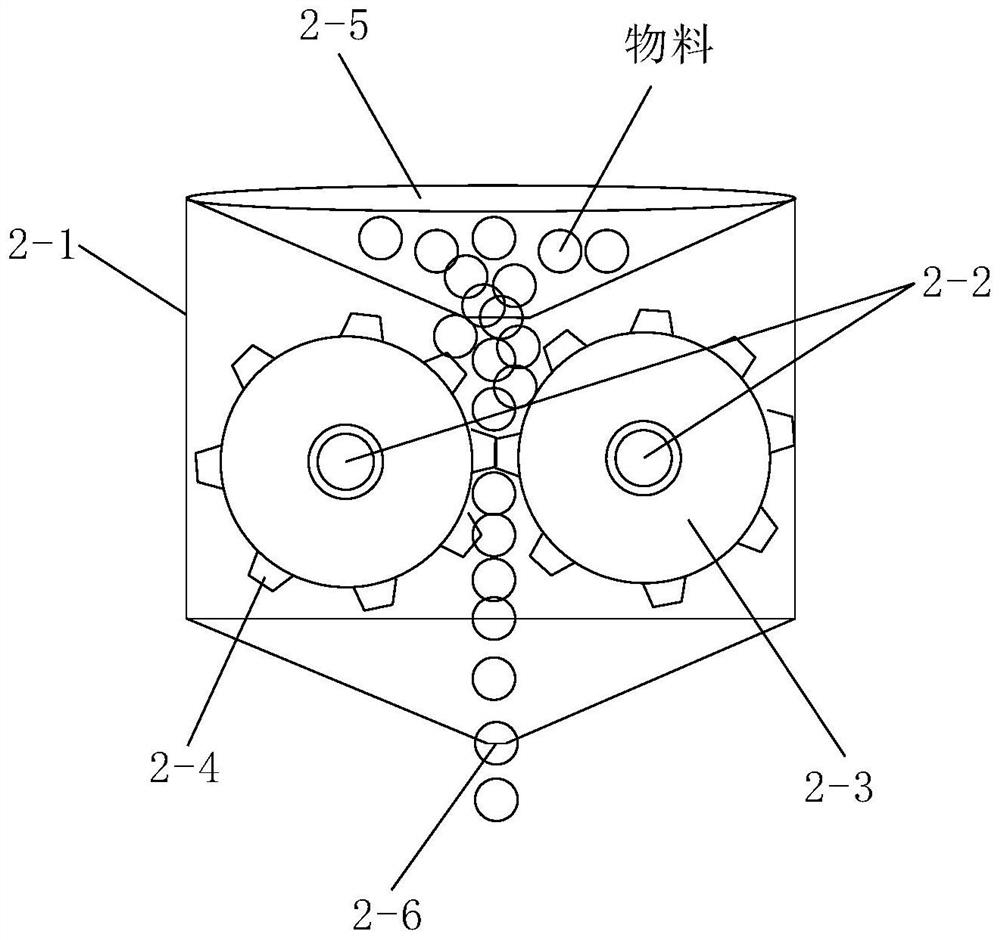

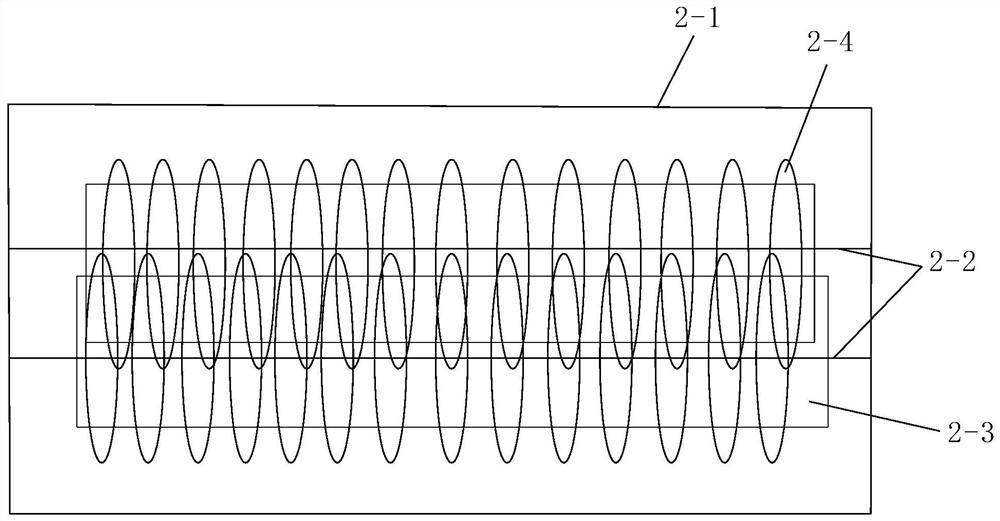

A method and equipment for remediating heavy metal polluted soil

InactiveCN104226678BEasy dischargeImprove repair effectContaminated soil reclamationFiltrationResource utilization

The invention discloses a heavy metal-contaminated soil restoration method and equipment thereof. The heavy metal-contaminated soil restoration method includes the steps of crushing, sieving, cleaning, sedimentation, chemical addition reaction and standing maintenance. The equipment in the method includes successively connected crushing equipment, vibrating screening equipment, stone washing equipment, sedimentation tank, defiltration equipment, dosing equipment and stirring equipment. The heavy metal-contaminated soil remediation method of the present invention has a high degree of systematicness and continuous operation, which is beneficial to the overall control and management of the contaminated soil treatment process, reduces the construction work surface, reduces the secondary pollution of the environment, and improves the utilization rate of resources in the system. And it can improve the effect and efficiency of soil remediation and reduce the cost of soil remediation.

Owner:周昱

A kind of polyester film and manufacturing method thereof

The invention provides a polyester film. The polyester film comprises 90-98 percent by mass of a film grade polyester chip and 2-10 percent by mass of a polyester masterbatch chip. A manufacture method of the polyester film comprises corresponding special process parameters in melt extrusion, cooling roll, longitudinal stretching and transverse stretching processes. The polyester film has the beneficial effects that the catalyst component in the raw materials of the polyester film is a titanium homogeneous catalyst, can be used for manufacturing food package, such as plastic food boxes, fast-food boxes, cake boxes, moon-cake box holders and other package films, and can be used for realizing the effect of environment friendliness and no toxicity. According to the polyester film product, corresponding process conditions are set in the production process, so that a product has high-transparency, is non-toxic and odorless, and has the characteristics of high chemical resistance, high temperature resistance, aroma retaining property, good concealing property to ultraviolet ray, good insulation to oxygen and the like.

Owner:TIANJIN SHIQI TECH DEV

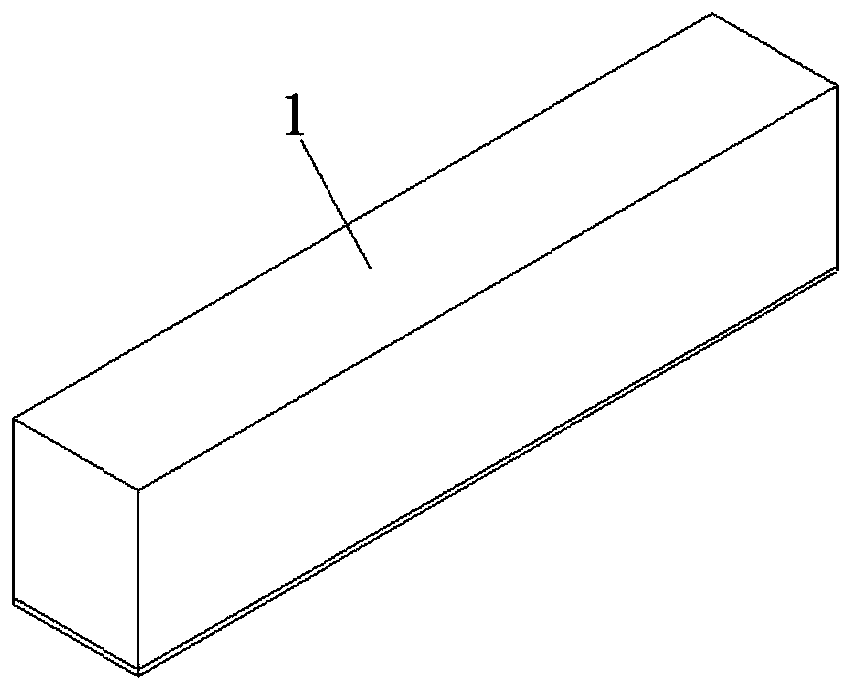

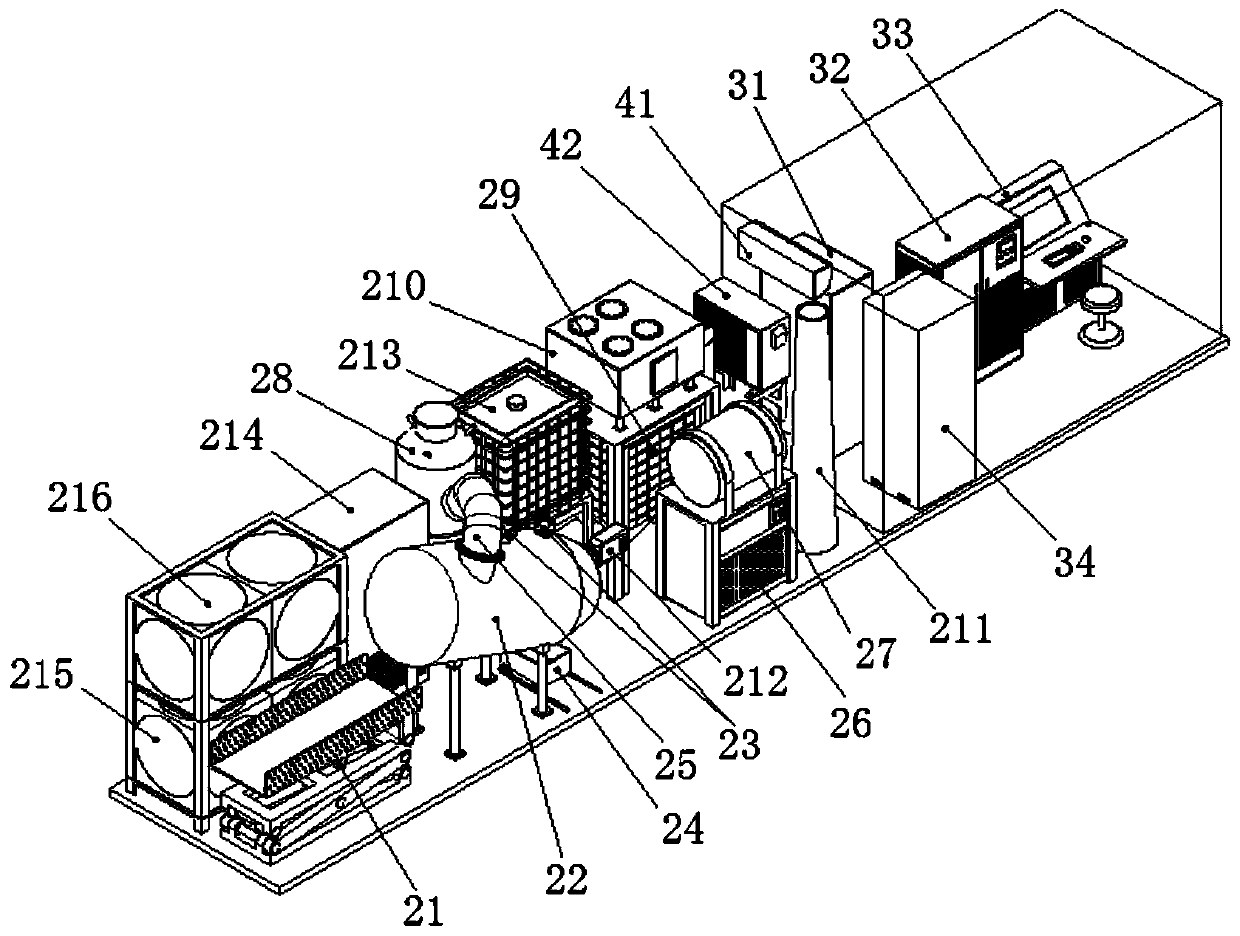

High-temperature plasma organism disposal shelter and disposal method

PendingCN111536521AIncrease gasification melting rateHigh gasification melting decomposition efficiencyIncinerator apparatusCombustion chamberFlue gas

The invention discloses a high-temperature plasma organism disposal shelter and a disposal method. The shelter comprises a shelter body and a disposal system, wherein a disposal area is arranged in the shelter body, and the disposal system is arranged in the disposal area of the shelter body; and the disposal system comprises a plasma gasification melting furnace, a slag fishing device, a secondary combustion chamber section, a quenching deacidification tower, a dust remover, a hydroxyl generator and a chimney, wherein the plasma gasification melting furnace is used for carrying out gasification decomposition treatment on organisms, the slag fishing device is arranged at a slag discharge port of the plasma gasification melting furnace, and a flue gas outlet of the plasma gasification melting furnace is connected with a flue gas inlet of the secondary combustion chamber section. According to the disposal shelter, gasification decomposition is carried out on the organisms in a high-temperature reducing atmosphere, and dioxin is not generated in the gasification decomposition process; and by arranging the secondary combustion chamber section, the quenching deacidification tower, the dust remover and the hydroxyl generator, deacidification, denitrification and salinity treatment on flue gas generated by gasification and decomposition are achieved, secondary pollution is avoided, complete harmless treatment of organisms is achieved, the volume reduction effect is remarkable, harmless treatment is thorough, and the organic matter burn-down rate is high.

Owner:西安太乙鼎生航天环保科技有限公司

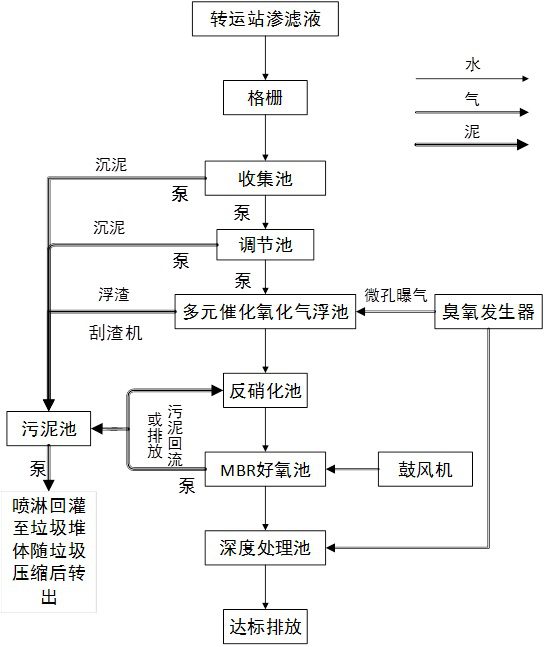

Leachate treatment method suitable for small and medium-sized refuse transfer stations

InactiveCN112979090AEasy to solveImprove biodegradabilityWater contaminantsTreatment involving filtrationSludgeOrganic matter

The invention relates to a leachate treatment method suitable for small and medium-sized refuse transfer stations, which comprises the following steps of: filtering refuse leachate by using a grid to remove massive refuse; adjusting the pH to 6.5-7.5; carrying out electro-catalysis ozone micro-aeration air flotation modification and deslagging; removing nitrogen through denitrification, and biochemically degrading organic matters; carrying out deep treatment, and recycling or discharging the treated wastewater; recharging the sludge into the garbage heap, compressing and then transferring the product out along with the station body. According to the treatment method disclosed by the invention, the use of chemicals is reduced as much as possible while the treatment quality of the landfill leachate of the transfer station is ensured, unnecessary processes and equipment are reduced, and the treatment investment, operation and maintenance costs of the landfill leachate of the transfer station are reduced to the greatest extent.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

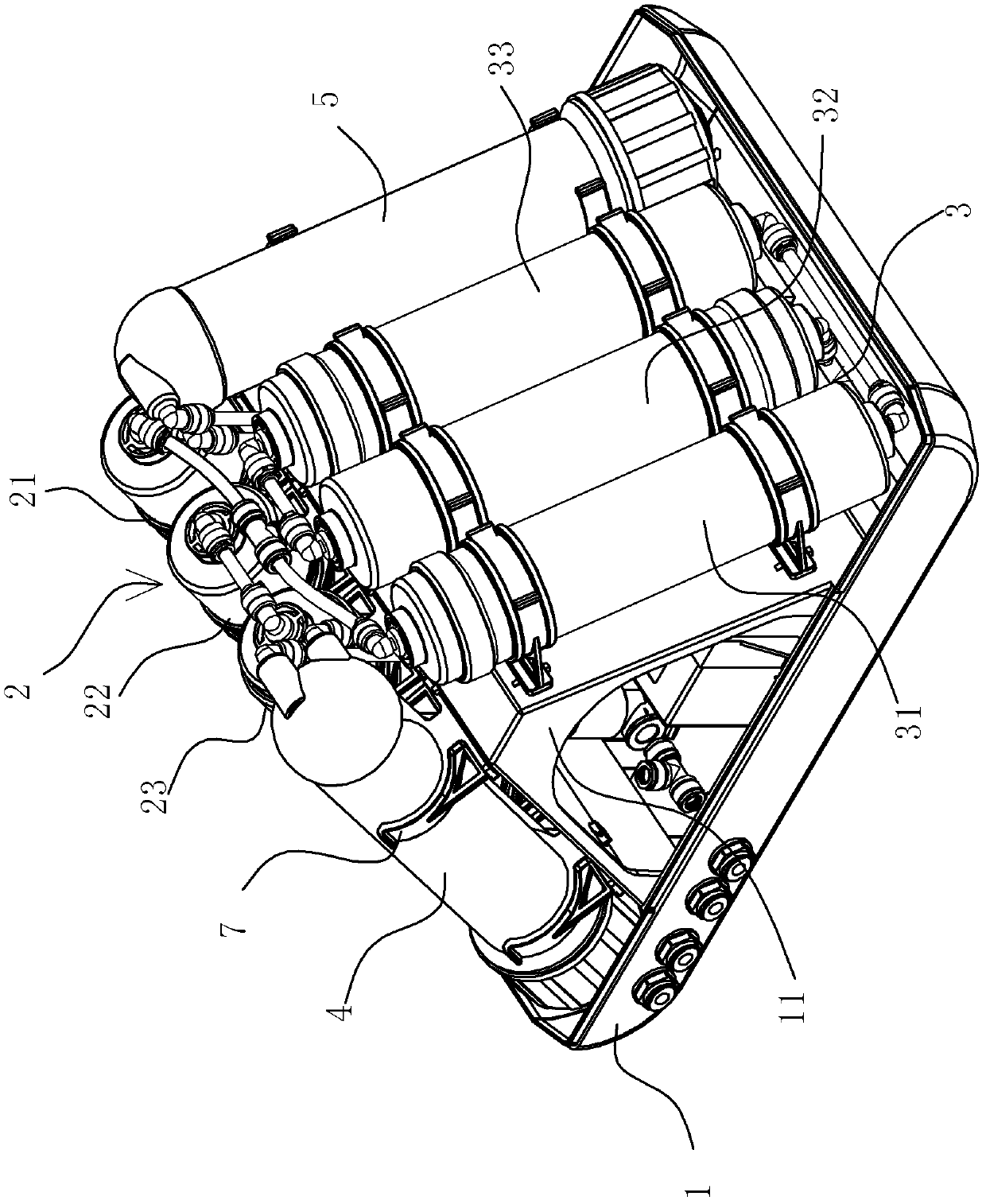

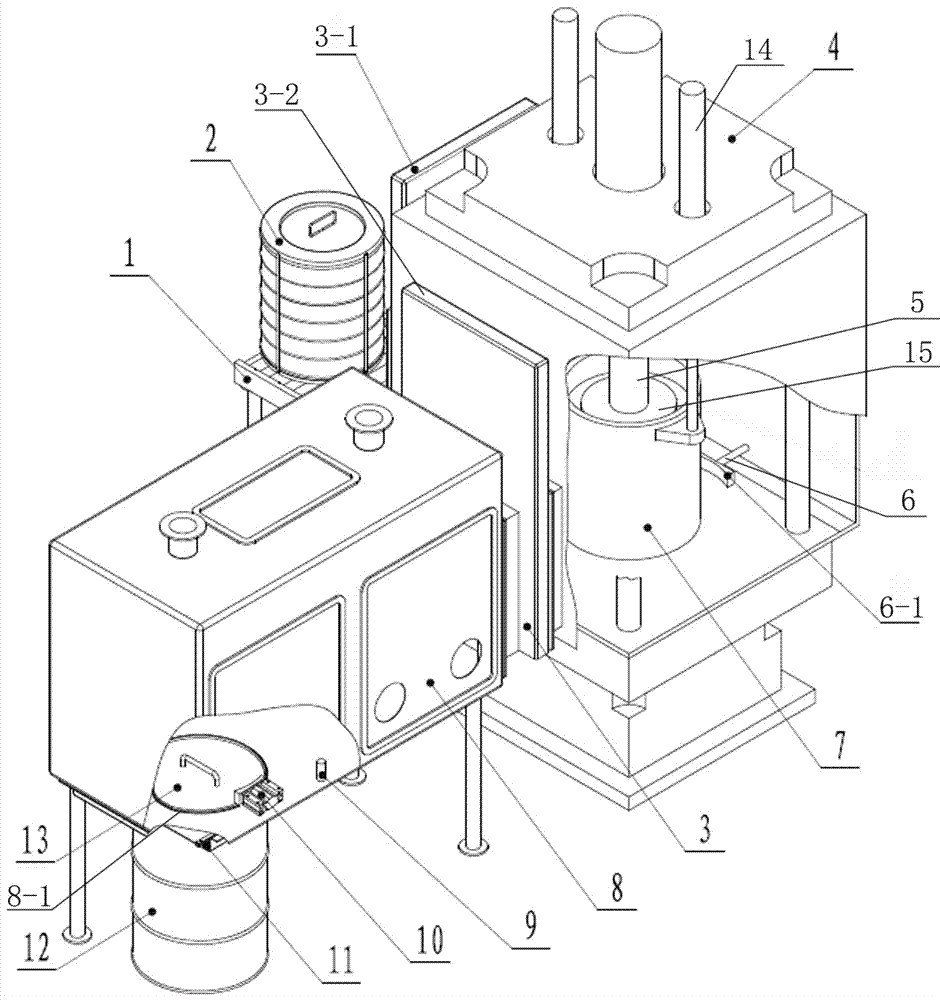

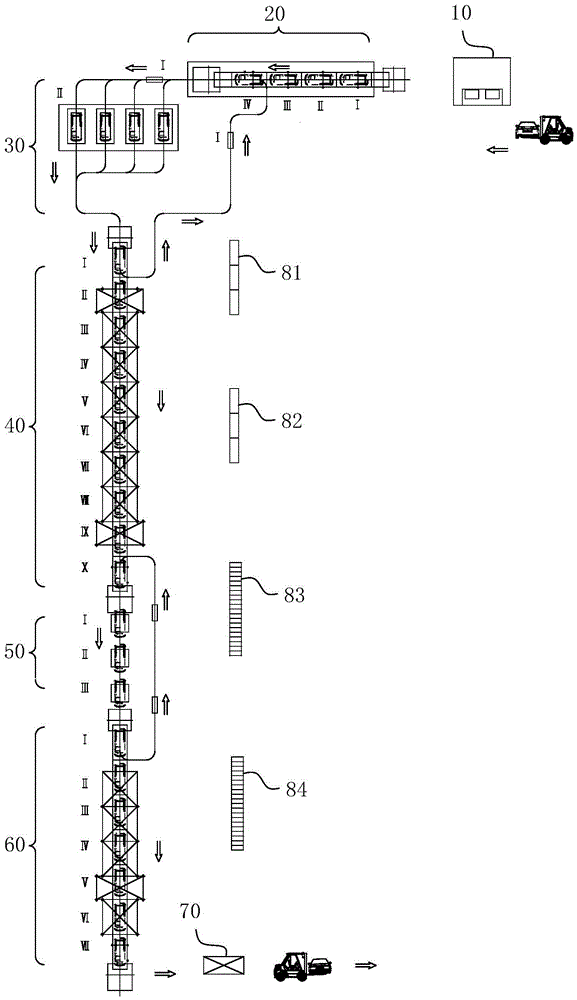

Retired passenger car dismantling system

ActiveCN104176153BNo secondary pollutionRealization of secondary pollutionVehicle dissasembly recoverySolid waste disposalChain conveyorMiddle line

The invention belongs to the technical field of vehicle dismantling, and in particular relates to a decommissioned passenger car dismantling system based on efficient and fine dismantling of retired passenger cars. The present invention at least includes a main dismantling line system, and the main dismantling line system at least includes an environmental protection pretreatment line, an oil pumping line in the air, a vehicle front dismantling line, and an engine and chassis aerial dismantling line that are successively arranged from front to back. Line unraveling, body dismantling line and body flattening line; environmental protection pretreatment line, car front dismantling line and body dismantling line constitute the ground dismantling station, and all the ground stations are connected with each other by the plate chain ground conveyor belt; The oil aerial line and the engine and chassis aerial dismantling line constitute the aerial dismantling station. The present invention can effectively realize the streamlining and refinement of the vehicle dismantling process, the dismantling efficiency is high, the recovery rate of parts after dismantling can be significantly improved, and at the same time, the impact on the surrounding environment can be greatly improved or even avoided.

Owner:TONGLING MIRACLE MECHANICAL EQUIP

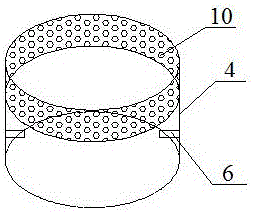

Underground living garbage can

InactiveCN106742927ASimple structureEasy to useWaste collection and transferRefuse receptaclesEngineeringPollution

The invention belongs to the technical field of the outdoor garbage can, and particularly relates to an underground living garbage can. The underground living garbage can comprises an outer barrel, a first inner barrel, a can cover, an intermediate barrel, a foot pedal and a baffle. The upper end of the outer barrel is connected with the can cover. The can cover is connected with the foot pedal. The bottom of the intermediate barrel contacts with the bottom face of the outer barrel. The upper part of the intermediate barrel is connected with the inner barrel by a hoop. The intermediate barrel is provided with the baffle. The barrel bottom of the first inner barrel is arranged on the baffle. The first inner barrel comprises a first inner barrel bottom and a first inner barrel body. One end of the first inner barrel bottom is connected with the first inner barrel body by a hinge, and the other end is connected with the first inner barrel body by a pin shaft. The upper part of the first inner barrel body is provided with lifting ears. The first inner barrel bottom is provided with through holes. The inner surface of the first inner barrel bottom is provided with pricking pins. The through holes and the pricking pins are alternately installed. The underground living garbage can has the characteristics of simple structure and convenient use, and is capable of realizing the separated treatment of the solid garbage and the liquid garbage, and reducing the environment pollution.

Owner:大连圣多教育咨询有限公司

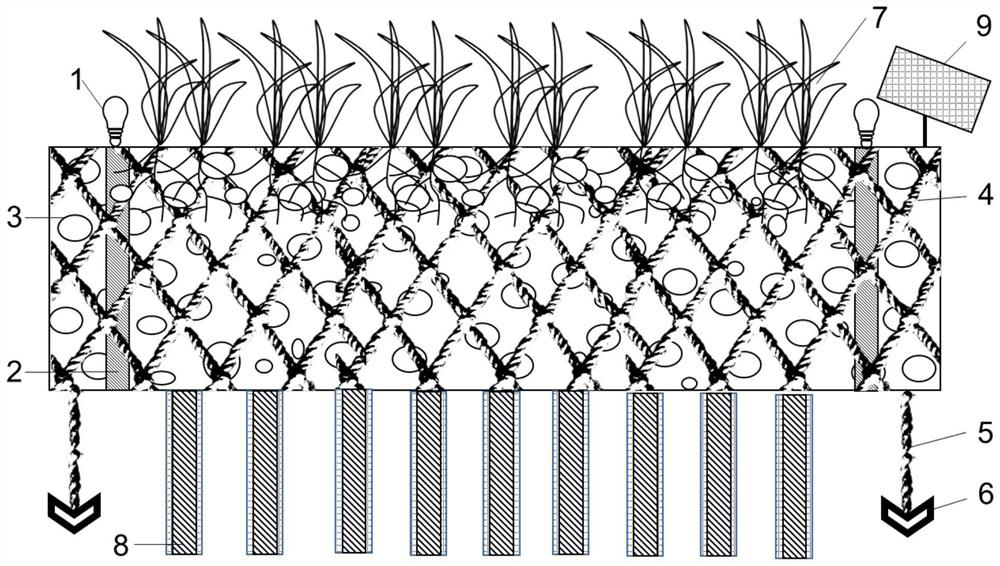

A biomass carbon-based multifunctional floating wetland system

ActiveCN112573663BPromote growthImprove purification effectTreatment by combined electrochemical biological processesClimate change adaptationLED lampWetland

The invention discloses a biomass charcoal-based multifunctional floating wetland system for repairing contaminated water bodies, comprising: a sponge charcoal floating bed; a fixed net; a fixing device; a biomass charcoal electrode; an LED lamp; Electrode biofilm device below the floating bed. The invention adapts to the stable requirements of different water conservancy conditions, can be applied to repair various water bodies such as river channels, and can effectively reduce the content of pollutants such as nitrogen, phosphorus, organic matter and other pollutants in the water body; the biomass-based sponge charcoal used in the invention not only avoids the use of additional buoyancy It can also promote the growth of wetland plants, solve the problem of low survival rate of traditional floating bed plants, and the floating body is easy to cause secondary pollution, quickly build a water ecological landscape, and improve environmental effects; the present invention can generate electricity while removing pollutants. LED lights emit light without additional power consumption; and the floating wetlands can grow commercial crops, increase economic value, and have obvious economic benefits.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Organic garbage and sludge mixed solid fuel and preparation method thereof

InactiveCN101215488BImprove thermal efficiencyHigh mechanical strengthSolid fuelsWaste based fuelSludgePetroleum

Owner:TIANJIN URBAN CONSTR COLLEGE

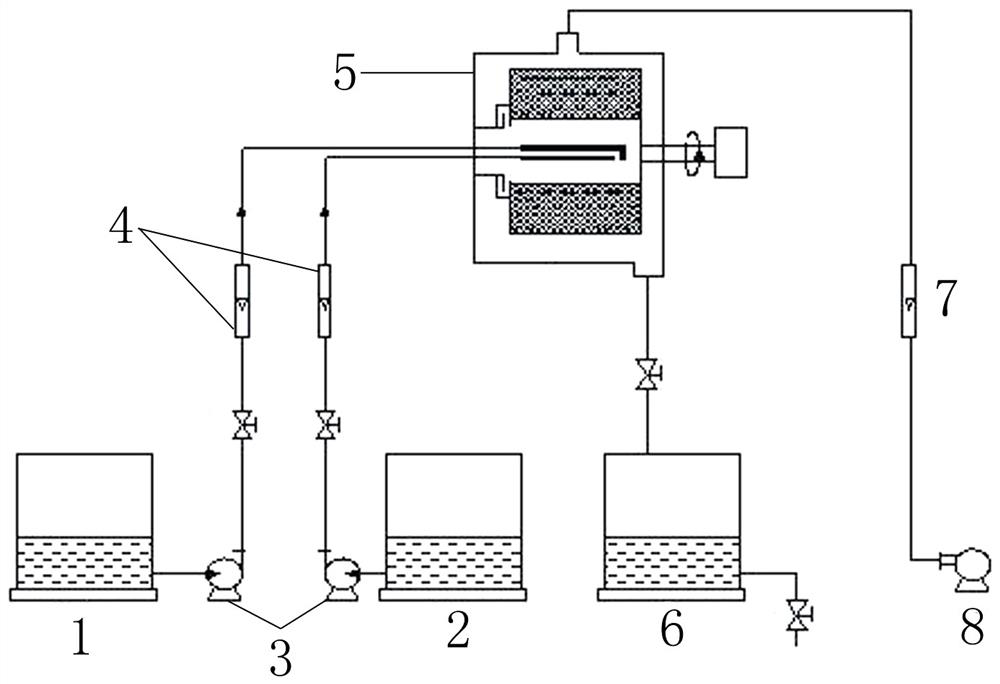

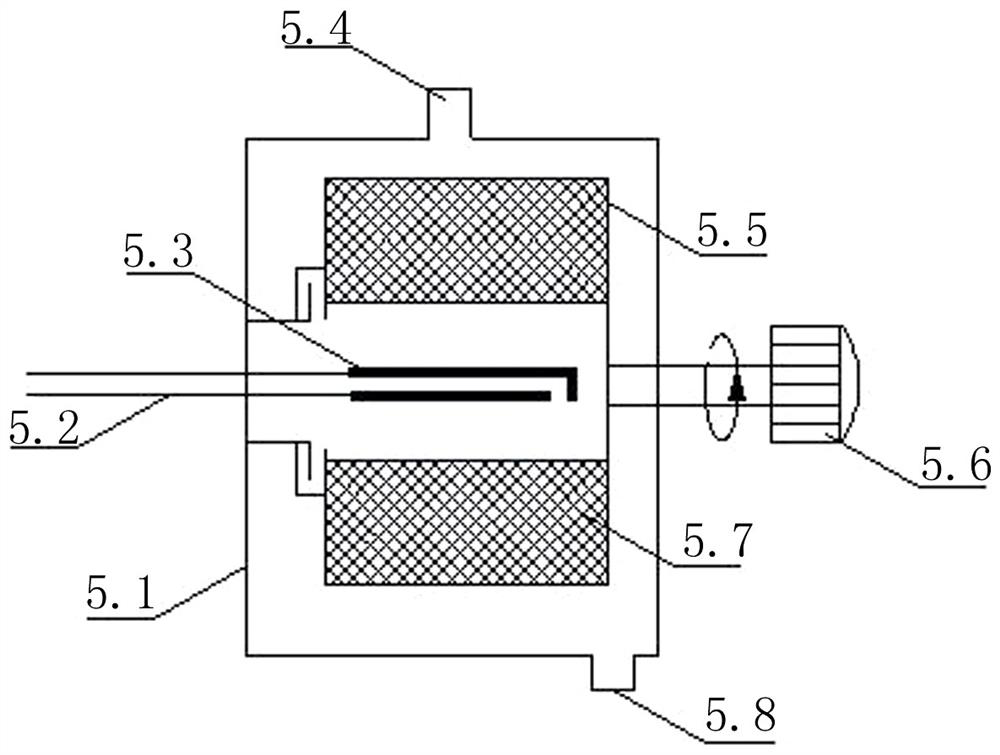

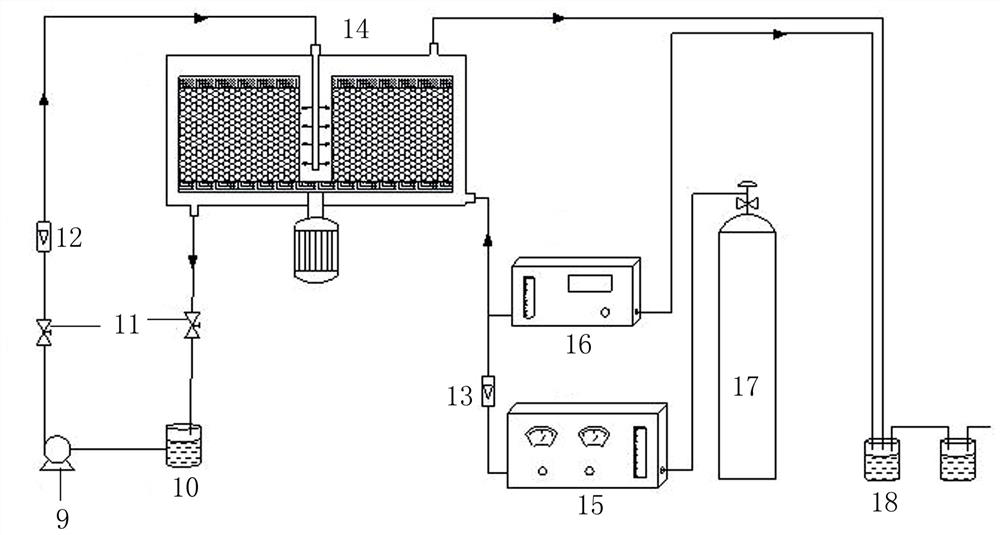

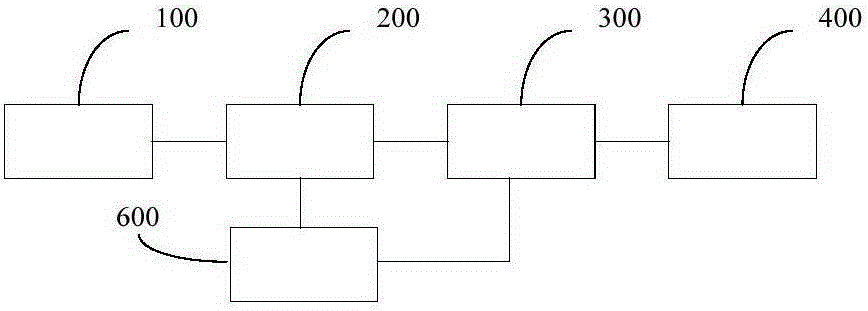

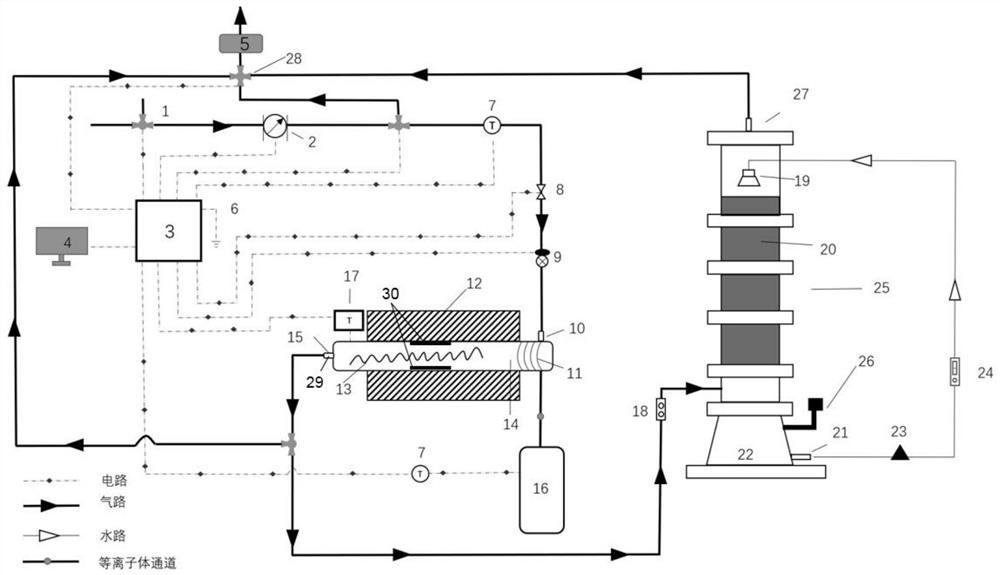

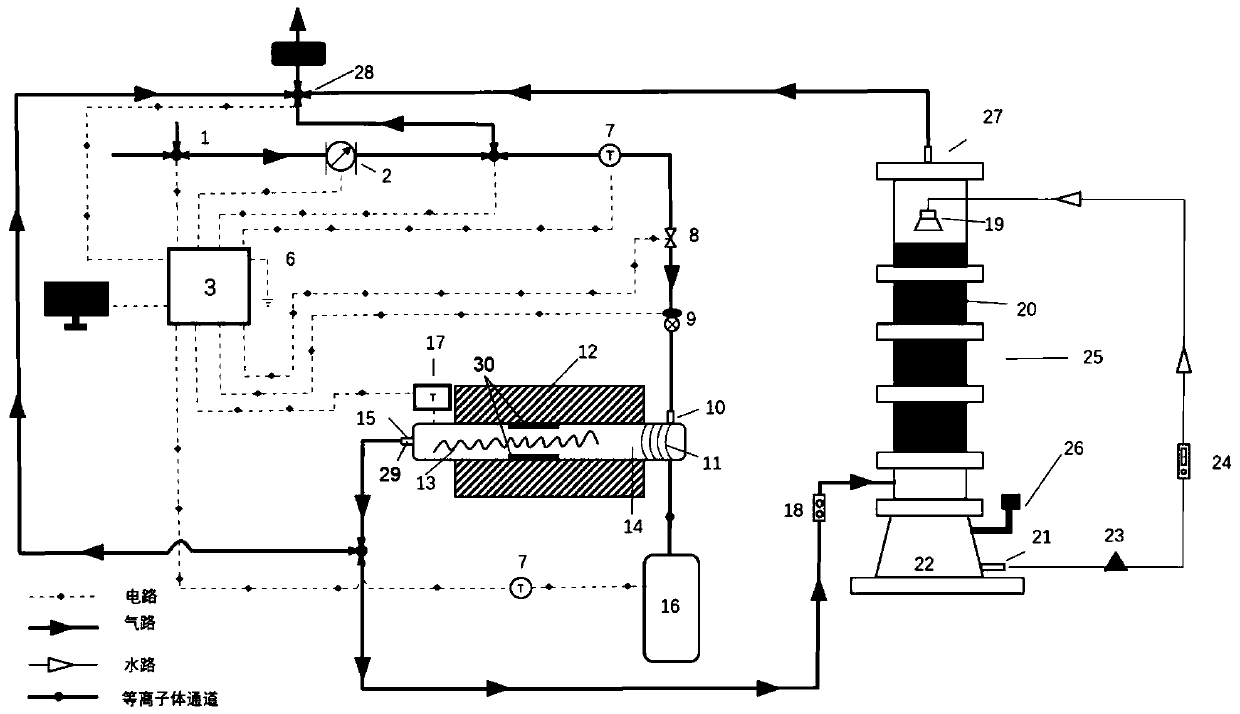

A method for processing low-temperature plasma-biological integrated reaction system

ActiveCN111420526BImprove processing precisionImprove processing efficiencyGas treatmentDispersed particle separationPtru catalystReal-time data

The invention discloses a method for using a low-temperature plasma-biological integrated reaction system for treating organic waste gas. In the insulating layer, and in the gas outlet tube wall of the low-temperature plasma reaction device, Mn-Al is coated 2 o 3 Catalyst coating: Integrates precise control of gas flow, high-efficiency pretreatment of low-temperature plasma, and high-efficiency gas-liquid-solid three-phase reaction, and has obvious advantages such as secondary pollution control, high control precision, excellent safety performance, and high degree of automation. The reaction system of the present invention uses PLC to dynamically adjust and automatically and accurately adjust parameters such as discharge voltage and liquid-gas ratio according to real-time data feedback, which can effectively improve the precision and efficiency of pollutant treatment, solve the impact of secondary pollution, reduce operating costs and system energy consumption, and realize With the automation of the system, the waste gas and pollutant treatment capacity has been significantly improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

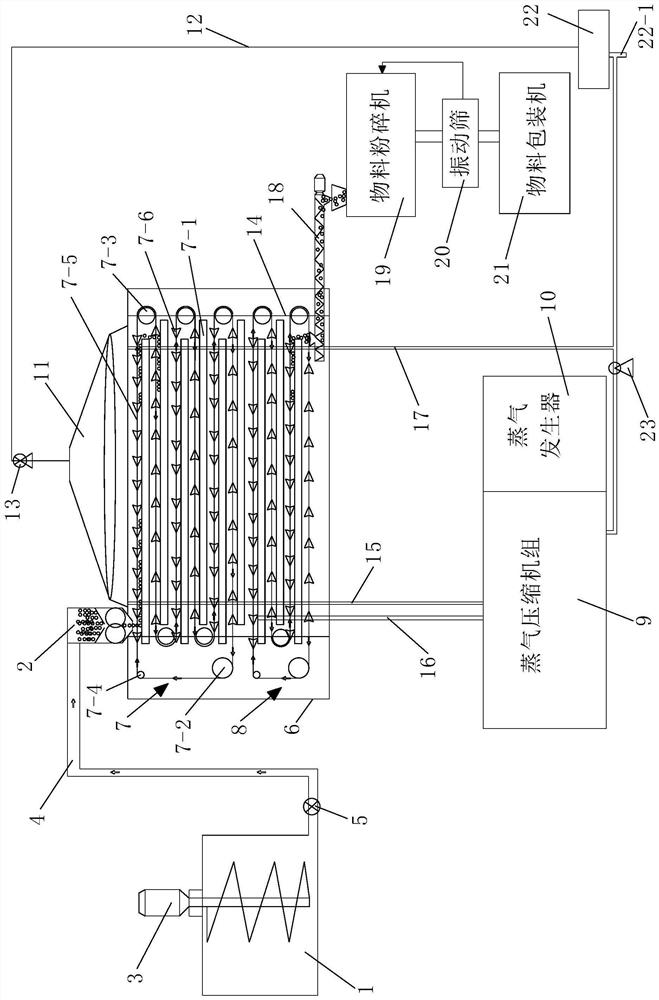

Well drilling waste mud recycling and reusing low-temperature treatment system

PendingCN114590985AKeep aliveOn holdSludge treatment by de-watering/drying/thickeningWell drillingProcess engineering

The invention discloses a well drilling waste mud recycling and reusing low-temperature treatment system which comprises a well drilling waste mud collecting and pumping system, a material distributor, a low-temperature drying mechanism, a steam generating and conveying system and a material post-treatment system. The steam generating and conveying system is connected with the low-temperature drying mechanism; the material post-processing system is arranged at a material outlet of the low-temperature drying mechanism; the well drilling waste mud collecting and pumping system comprises a well drilling waste mud collecting pool, a mud stirrer, a mud conveying pipeline and a single-screw pump, the mud stirrer is installed in the well drilling waste mud collecting pool, one end of the mud conveying pipeline is connected with an outlet of the well drilling waste mud collecting pool, and the single-screw pump is installed on the mud conveying pipeline. The device is simple in structure and convenient to use, the drilling waste mud can keep the original activity of the mud when treated in a low-temperature state, and the device can be reused without waste, has no pollution hidden danger and is low in treatment cost.

Owner:商洛市海蓝科技有限公司

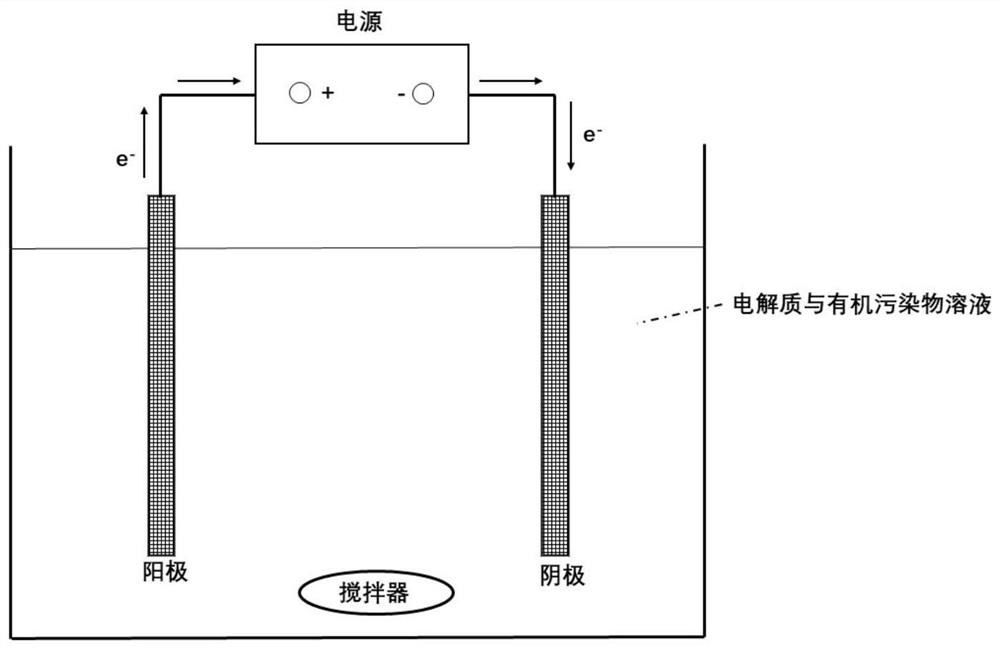

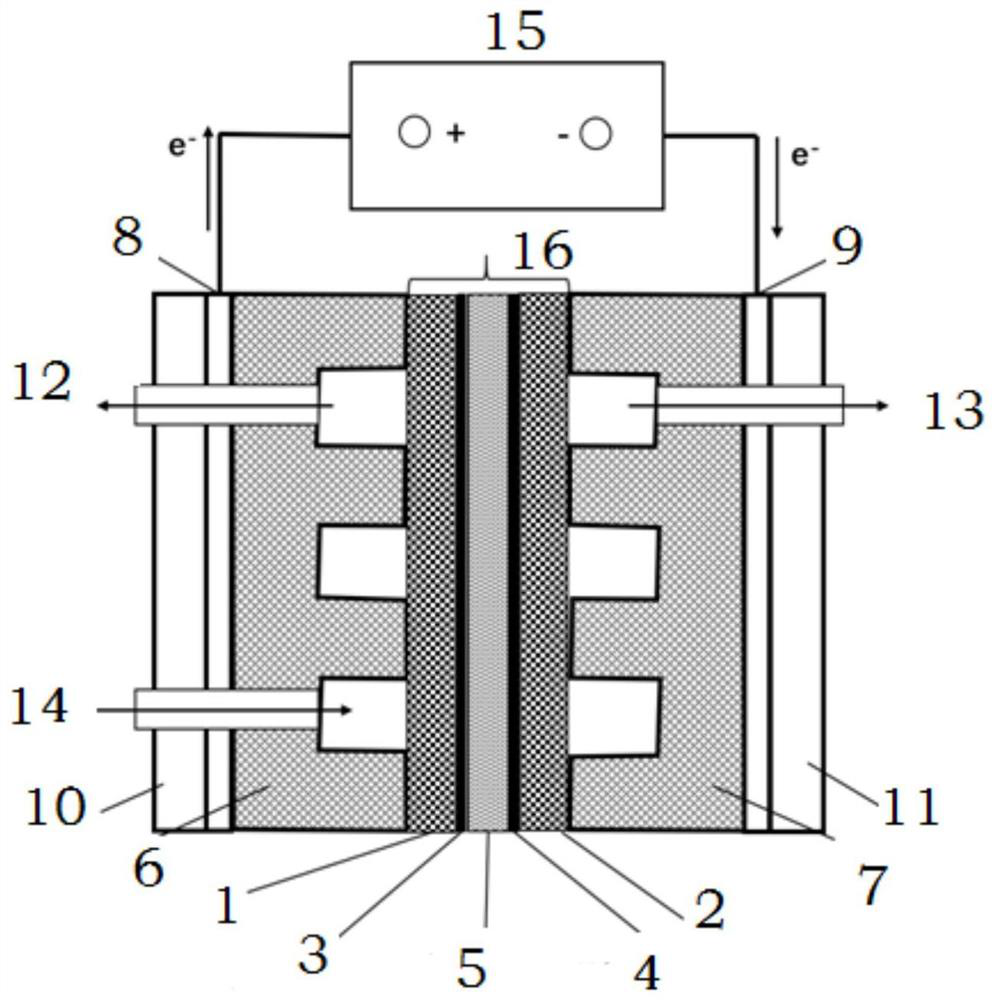

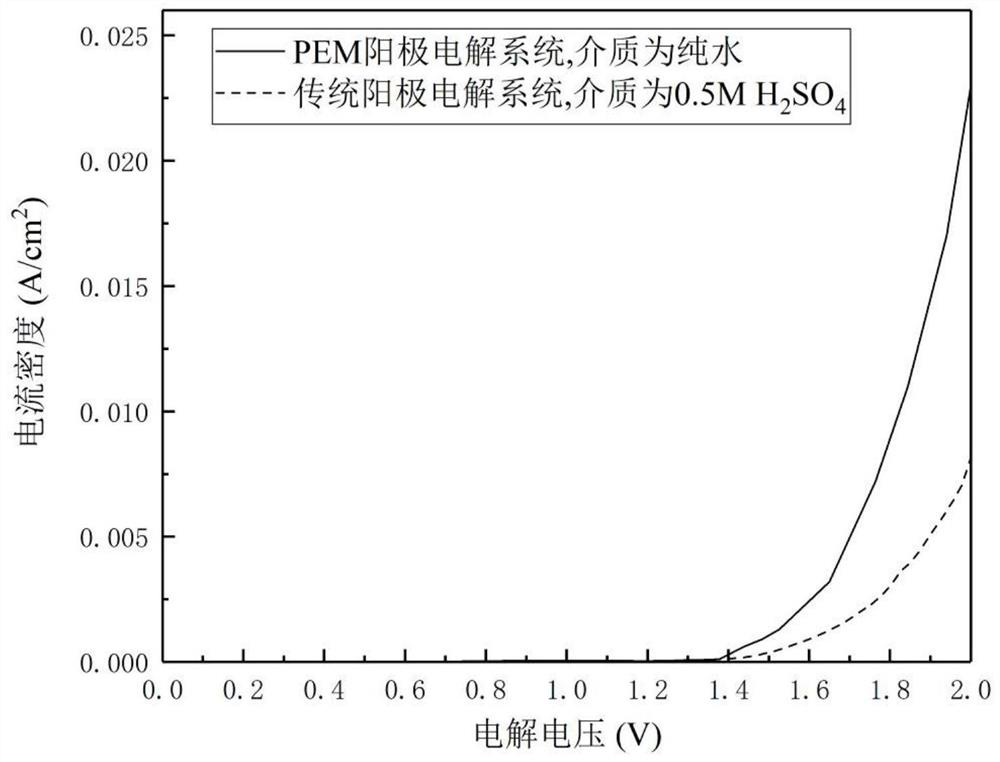

Organic pollutant anodic oxidation treatment device based on proton exchange membrane

PendingCN113135614AFast ion mass transfer velocityMass transfer speedWater contaminantsWater/sewage treatment using germicide/oligodynamic-processChemical physicsCathode electrode

The invention relates to an organic pollutant anodic oxidation treatment device based on a proton exchange membrane. The device comprises a power supply and an electrolytic bath which are electrically connected, a membrane electrode assembly is arranged in the electrolytic bath, and the membrane electrode assembly divides the electrolytic bath into a positive electrode area electrically connected with a positive electrode of the power supply and a negative electrode area electrically connected with a negative electrode of the power supply; and an anode electrode plate and an anode bipolar plate are arranged in the anode region, a cathode electrode plate and a cathode bipolar plate are arranged in the cathode region, and the anode bipolar plate and the cathode bipolar plate are both in contact with the membrane electrode assembly and define a plurality of reaction tanks and the like with the membrane electrode assembly respectively. The device is high in current density, low in energy consumption and high in unit area processing speed. The proton exchange membrane is used as an ion conduction channel, the ion conduction impedance is low, the ion mass transfer speed is high, and the current density is higher than that of traditional anodic oxidation treatment under the same voltage, so that the energy consumption is reduced while the treatment speed is increased.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Rotary flushing process for coal chemical gasified slag

PendingCN113843262ARealize reprocessing to formAchieve secondary utilization processingSolid waste disposalPorous carbonSlag

The invention provides a rotary flushing process for coal chemical gasified slag, and relates to the technical field of gasified slag treatment processes. The flushing process comprises the following steps that 1, primary separation processing is carried out on the gasified slag, and impurity-containing porous silicon and porous carbon are formed from the primarily separated gasified slag; 2, the obtained porous carbon is subjected to secondary separation processing, and porous carbon particles and fine sand are formed by the porous carbon subjected to secondary separation; 3, primary dehydration processing is carried out on the obtained porous carbon particles, and the porous carbon particles subjected to the primary dehydration processing form water-containing porous carbon and fine powder; 4, secondary dehydration processing is carried out on the obtained high-purity porous carbon to form anhydrous porous carbon; 5, the obtained fine powder is dehydrated to form carbon powder; 6, the obtained fine sand is dehydrated to form carbon sand; and 7, the obtained porous silicon is sequentially subjected to primary separation processing, centrifugal dewatering processing and vibrating screen separation processing, and carbon sand and porous silicon are formed through vibrating screen separation processing. According to the flushing process, reutilization of the gasified slag can be realized, and secondary pollution to the environment is avoided.

Owner:喻勇 +1

Hydrothermal Harmless Treatment of Waste Incineration Fly Ash

ActiveCN111672876BReduce utilizationIncrease profitSolid waste disposalTransportation and packagingContamination controlHydrothermal reaction

The invention discloses a method for hydrothermal harmless treatment of waste incineration fly ash, which comprises the following steps: (1) adding hydroxyapatite precursor liquid to the fly ash, and then performing the first step at 40-50°C Pressurized hydrothermal reaction to stabilize heavy metals in fly ash; (2) Add magnetic hydroxyapatite powder and hydrogen peroxide to the mixture obtained in step (1), and then carry out the second step of microwave high-pressure hydrothermal heating at 120-150°C reaction, further stabilizing heavy metals in fly ash and degrading polycyclic aromatic hydrocarbons. The invention can efficiently and synchronously realize the stabilization of heavy metals in waste incineration fly ash and the degradation and detoxification of polycyclic aromatic hydrocarbons. Not only the leaching toxicity of heavy metals is lower than the identification standard of hazardous waste, but also can be reduced to meet the "Standards for Pollution Control of Domestic Waste Landfill Sites", The heavy metals are really stable in the fly ash instead of being transferred to the hydrothermal waste liquid on a large scale, and the toxic equivalent degradation rate of 16 kinds of polycyclic aromatic hydrocarbons is over 95.06%, and secondary pollution is prevented.

Owner:CHONGQING UNIV

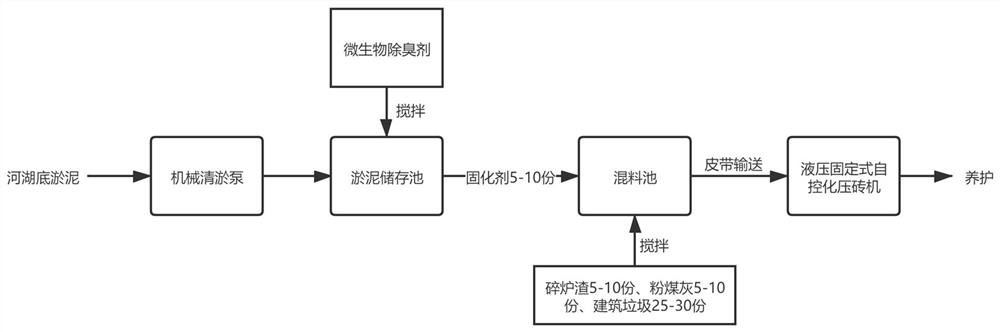

Preparation method of novel ecological slope protection material

PendingCN113442286AHarmless in syncSynchronize resourcesCement productionClay mixing apparatusBrickSludge

The invention provides a preparation method of a novel ecological slope protection material. The preparation method comprises the following steps that S1, sludge is pumped through an environment-friendly cutter suction type dredging pump, filtered through a primary filter screen technology and then enters a sludge storage pool; S2, a microbial deodorant is sprayed in the sludge storage pool for deodorization; S3, the deodorized sludge enters a sludge concentration tank through a pipeline to be pretreated, and the pretreated sludge is conveyed into a mixing tank; S4, crushed slag, fly ash and construction waste are added into the mixing tank to serve as brick making raw materials, the raw materials are mixed with supernate obtained by concentrating and digesting the sludge, meanwhile, a curing agent is supplemented to conduct curing treatment on the mixed materials, and the mixed materials do not form large bonding blocks after being mixed; and S5, static pressure molding is conducted on the mixed materials in the mixing tank through an automatic control brick press, and after molding, the mixed materials are transported into a curing room for curing. By the adoption of the above scheme, harmlessness and recycling of the sludge at the river bottom and the lake bottom can be achieved synchronously, the treatment cost is low, and economic benefits are good.

Owner:湖南凯迪工程科技有限公司

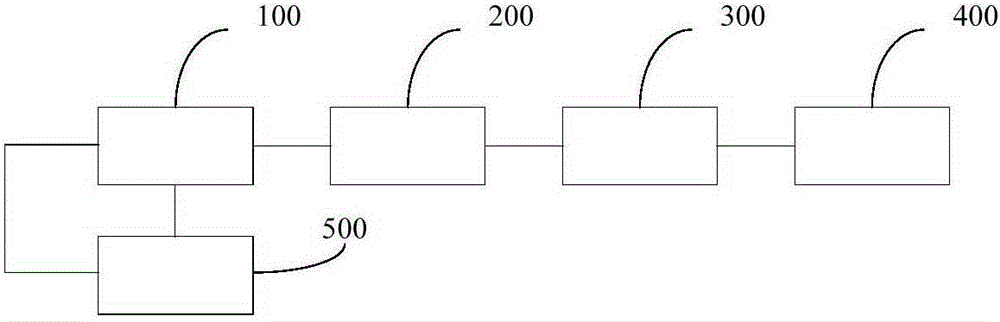

Low-temperature plasma-biological integrated reaction system for treating organic waste gas

ActiveCN111420525AImprove processing precisionImprove processing efficiencyGas treatmentDispersed particle separationControl cellEnvironmental engineering

The invention discloses a low-temperature plasma-biological integrated reaction system for treating organic waste gas. The system comprises a gas circuit control unit, a low-temperature plasma reaction device, a process parameter monitoring auxiliary system and a biotrickling reaction device; the gas circuit control unit is connected with the low-temperature plasma reaction device, and the low-temperature plasma reaction device is connected with the biotrickling reaction device; the system integrates gas flow accurate control, low-temperature plasma efficient pretreatment and gas-liquid-solidthree-phase efficient reaction, and has the obvious advantages of controlling secondary pollution (O3), being high in control precision, excellent in safety performance, high in automation degree andthe like. According to the reaction system, the PLC is used for dynamically adjusting and automatically and accurately adjusting parameters such as discharge voltage and liquid-gas ratio according toreal-time data feedback, so that the pollutant treatment precision and efficiency can be effectively improved, the secondary pollution influence is solved, the operation cost and the system energy consumption are reduced, the automation of the system is realized, and the waste gas and pollutant treatment capacity is obviously improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com