Method for removing and recovering arsenic and antimony in water body by replacement of copper powder

A technology of copper powder and water body, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage treatment, etc., to achieve the effect of easy realization, renewable utilization of resources, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

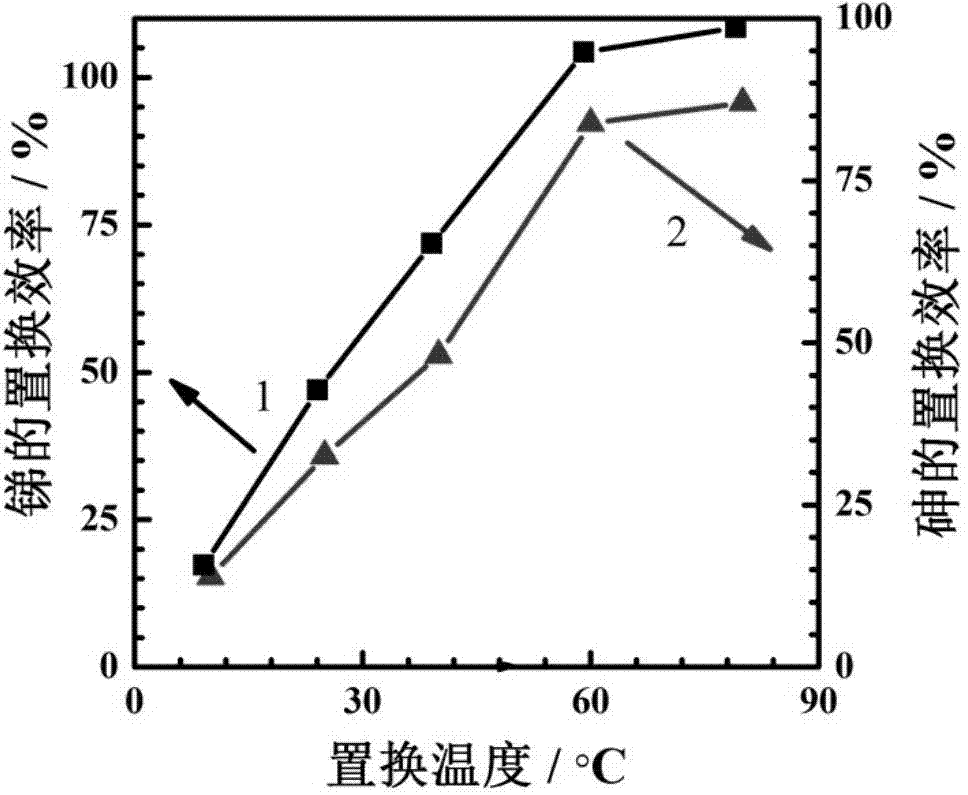

Image

Examples

Embodiment 1

[0020] Take 200mL As(III) content is 3.6gL -1 , Sb(III) content is 5.8gL -1 The silver slag leaching solution was placed in the reactor, the pH of the solution was adjusted to 0 with hydrochloric acid, 10g of copper powder (200 mesh) was added, the reactor was closed after nitrogen gas was introduced, the stirring speed was 400r / min, and the reaction temperature was 40°C. The time is 10-120 minutes.

[0021] Replacement efficiency was used to evaluate the replacement and removal effect of copper powder on arsenic and antimony in water.

[0022] Table 1 Experimental results of different replacement times

[0023] time / min

Embodiment 2

[0025] Take 200mL As(III) content is 8.2gL -1 , Sb(III) content is 13.8gL -1 The silver slag leaching solution was placed in the reactor, the pH of the solution was adjusted to 0 with hydrochloric acid, 10g of copper powder (400 mesh) was added, the reactor was closed after nitrogen gas was introduced, the stirring speed was 400r / min, and the reaction temperature was 40°C. The time is 10-120 minutes.

[0026] Replacement efficiency was used to evaluate the replacement and removal effect of copper powder on arsenic and antimony in water.

[0027] Table 2 Experimental results of different replacement times

[0028] time / min

[0029] 10

Embodiment 3

[0031] Take 200mL As(III) content as 0.1gL -1 , Sb(III) content is 0.5gL -1 surface water in the reactor, adjust the pH of the solution to 0 with hydrochloric acid, add 5g of copper powder (60 mesh), and seal the reactor after feeding nitrogen gas, the stirring speed is 400r / min, the reaction temperature is 40°C, and the replacement time is 10~120min.

[0032] Replacement efficiency was used to evaluate the replacement and removal effect of copper powder on arsenic and antimony in water.

[0033] Table 3 Experimental results of different replacement times

[0034] time / min

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com