Preparation method of convenient and fast nanofiber-based wiping cloth for nuclear pollution equipment

A technology of nanofiber and nuclear pollution, applied in the field of cleaning treatment, can solve the problems of secondary pollution of water body, expensive anti-diffusion migration, unacceptable and other problems, achieve large processing capacity, avoid secondary pollution, and be convenient and practical again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a nanofiber-based convenient wiping cloth for nuclear pollution equipment, the specific preparation method of which is:

[0027] 1. Using chitosan, chitin and polyvinyl alcohol as raw materials, dissolve the above raw materials in a solvent, stir at a temperature of -80°C at a stirring speed of 50-300 rpm, stir until completely dissolved, and let stand for 2 hours to remove bubble to obtain a hydrophilic polymer solution;

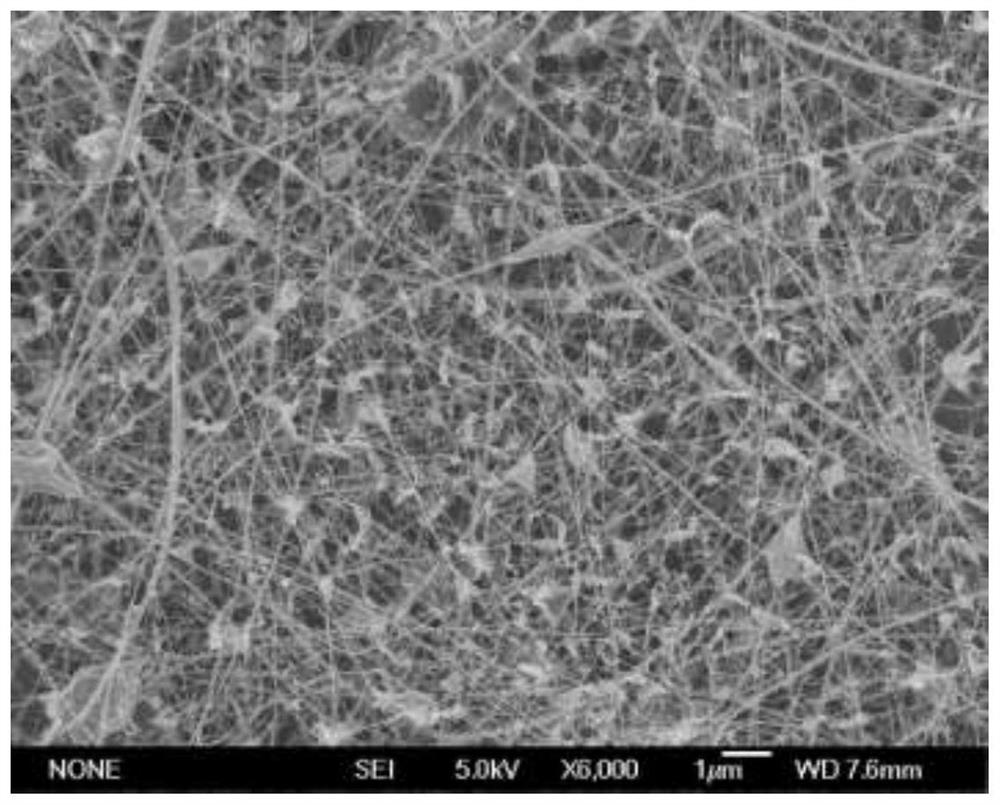

[0028] 2. Using electrospinning technology under the conditions of voltage 20kV, receiving distance 10cm, and spinning liquid supply volume 1.2mL / h; hydrophilic nanofibers were prepared in the above solution and prepared on non-woven fabric as the base material It is compiled into a wiping cloth, and the diameter distribution of the nanofibers is controlled within the range of 50nm-500nm, and the concentration is above 80%. within 5%.

[0029] 3. The above-mentioned wiping cloth is modified with a functional group, the mass r...

Embodiment 2

[0033] A method for preparing a nanofiber-based convenient wiping cloth for nuclear pollution equipment, the specific preparation method of which is:

[0034] 1. Using chitosan as a raw material, dissolve chitosan in a solvent, at room temperature -80°C, stir at a speed of 50-300 rpm, stir until completely dissolved, let it stand for 2 hours to defoam, and obtain hydrophilic polymer solution;

[0035] 2. Using electrospinning technology under the conditions of voltage 20kV, receiving distance 10cm, and spinning liquid supply volume 1.2mL / h; hydrophilic nanofibers were prepared in the above solution and prepared on non-woven fabric as the base material It is compiled into a wiping cloth, and the diameter distribution of the nanofibers is controlled within the range of 50nm-500nm, and the concentration is above 80%. within 5%.

[0036] 3. The above-mentioned wiping cloth is modified with functional groups, the mass ratio of spinning cloth and functional group reactants is 1: (1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com