Preparation method for quaternary ammonium salt modified attapulgite for heavy metal adsorption

A technology of attapulgite clay and modified attapulgite, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of many impurities, agglomeration, etc., and achieve simple and non-standard preparation process Secondary pollution, long-term effective control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

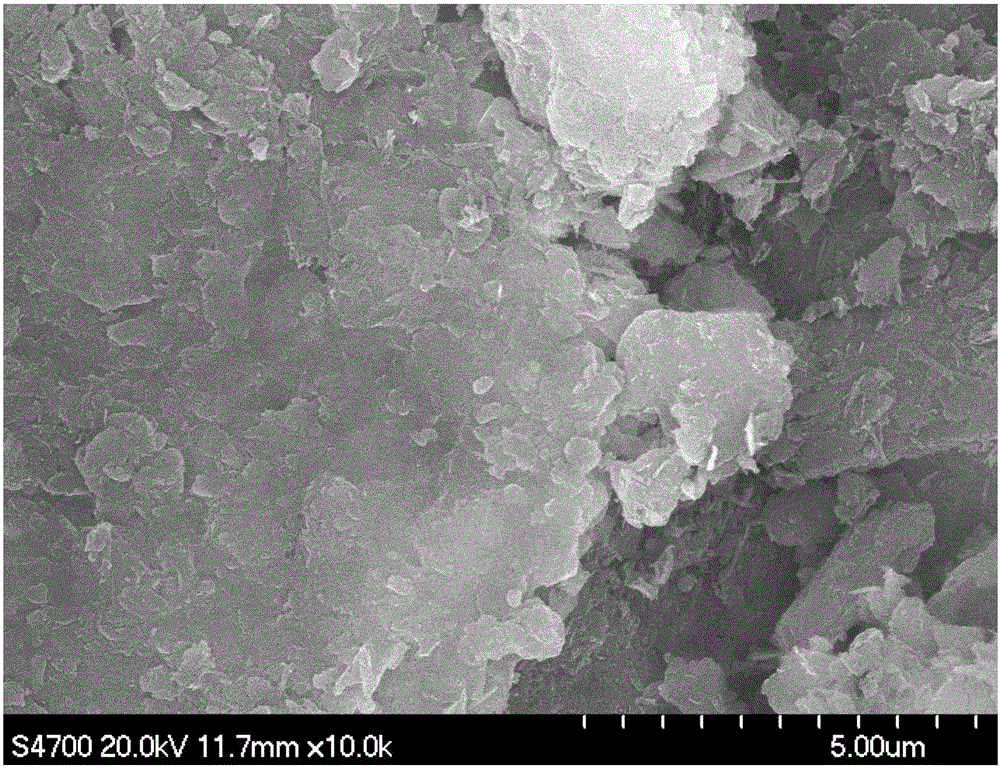

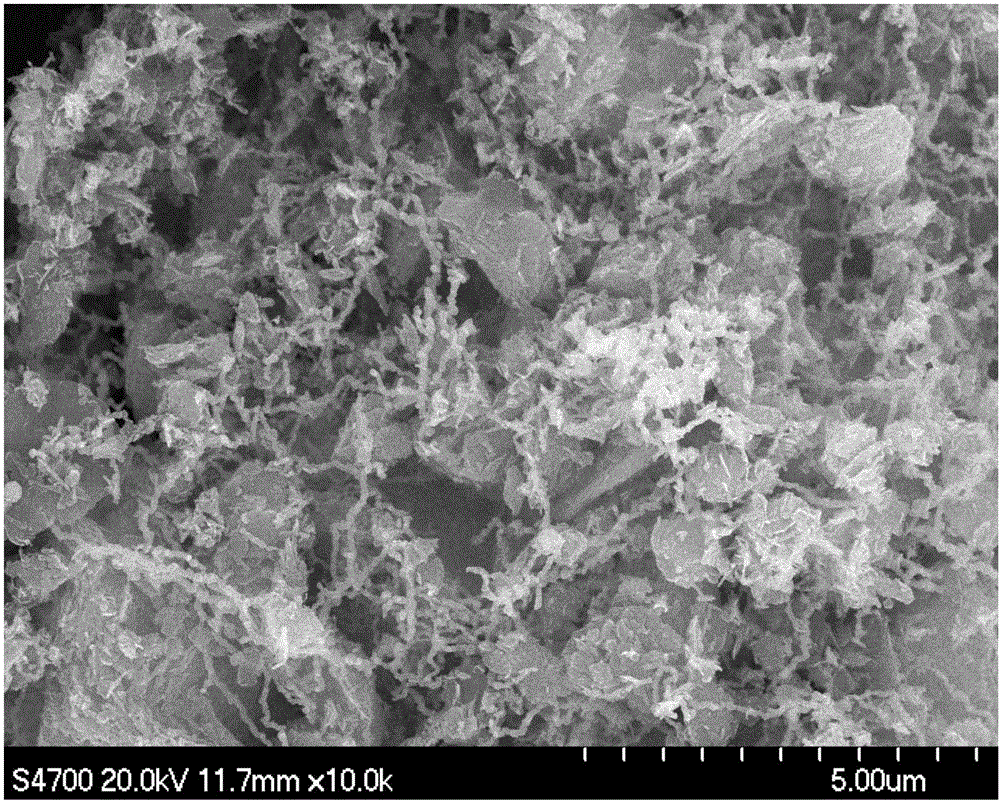

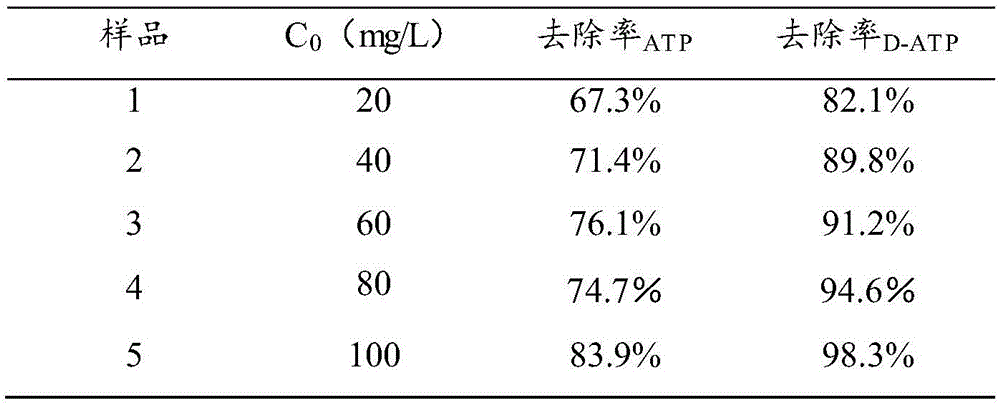

[0019] A preparation method of quaternary ammonium salt modified attapulgite clay for heavy metal adsorption. The material takes attapulgite clay as the core and grafts with quaternary ammonium salt on the surface. The specific preparation steps are as follows: 10g attapulgite The clay raw soil was added to 100ml of 5% dilute hydrochloric acid, mechanically stirred to make it fully mixed, reacted for 48 hours, centrifuged, filtered, and then washed repeatedly with deionized water. Wash until neutral, and titrate with silver nitrate until no precipitation occurs, then dry at 110°C, and pass through a 200-mesh sieve to obtain coarsely purified attapulgite clay; weigh about 0.8g of dioctadecyl dimethyl Ammonium chloride, octadecyltrimethylammonium chloride and other quaternary ammonium salts were added to 80mL of absolute ethanol (analytical pure) solution, and mechanically stirred to make it fully mixed to obtain a quaternary ammonium salt solution; weigh about 8g of Roughly pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com