Organic pollutant anodic oxidation treatment device based on proton exchange membrane

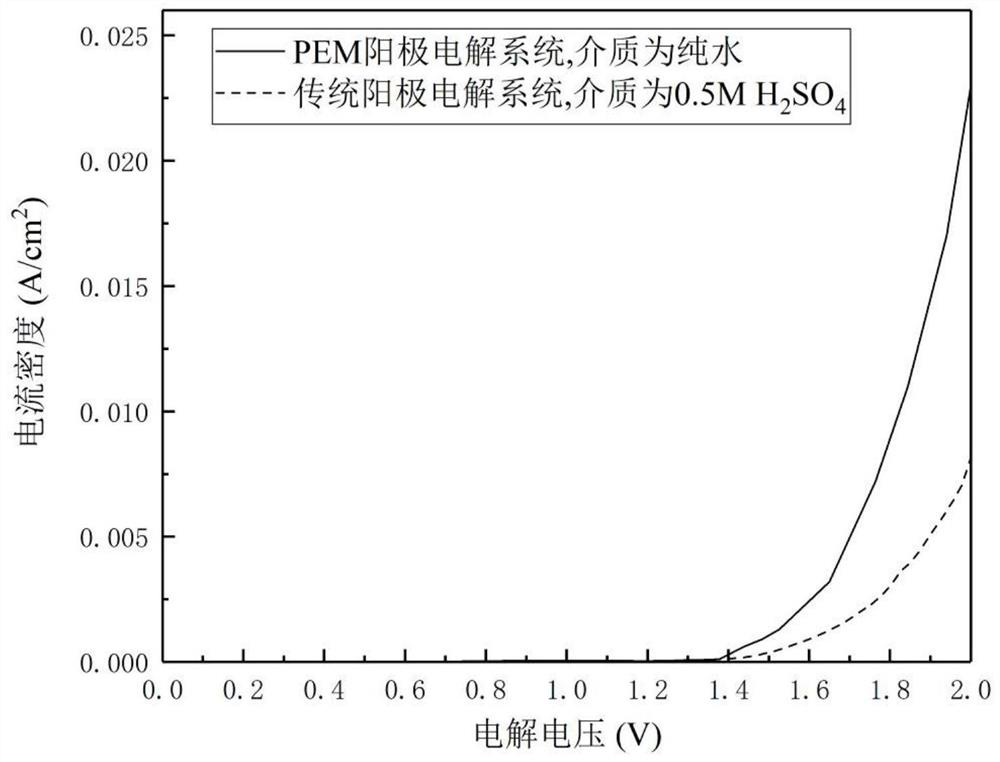

A technology of proton exchange membrane and anodic oxidation, which is applied in the direction of water pollutants, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of difficult electrolyte recovery, low electrode current density, frequent maintenance, etc., and achieve no Risk of corrosion and leakage, low ion conduction resistance, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: (preparation of anode catalyst)

[0059] A method for preparing an anode catalyst, comprising the steps of:

[0060] 1) A certain amount of SnCl 2 .2H 2 O and SbCl 3 Dissolve in water and ethanol mixed solution (alcohol accounts for 80%), the total concentration is 0.05mol / L, SnCl 2 .2H 2 O and SbCl 3 The molar ratio of the solution is 9:1, and the total volume of the solution is 1L.

[0061] 2) Prepare a saturated solution of NaOH with a mixed solution of water and ethanol (absolute ethanol accounts for 80%).

[0062] 3) Titrate 30 mL of the saturated solution prepared in step 2 into the SnCl prepared in step 1 while stirring 2 .2H 2 O and SbCl 3 solution and keep stirring for a while.

[0063] 4) Heat the solution prepared in step 3) to 120° C. and keep it warm for 24 hours.

[0064] 5) The reaction mixture obtained in step 4) is separated and cleaned by centrifugation and suction filtration to obtain the anode catalyst.

Embodiment 2

[0065] Embodiment 2 (preparation of anode catalyst)

[0066] A method for preparing an anode catalyst, comprising the steps of:

[0067] 1) A certain amount of SnCl 2 .2H 2 O and SbCl 3 Dissolved in a mixed solution of water and ethanol (alcohol accounts for 80%), the total concentration is 0.07mol / L, SnCl 2 .2H 2 O and SbCl 3 The molar ratio of the solution is 19:1, and the total volume of the solution is 1L.

[0068] 2) Prepare a saturated solution of NaOH with a mixed solution of water and ethanol (absolute ethanol accounts for 80%).

[0069] 3) Titrate 45mL of the saturated solution prepared in step 2) into the SnCl prepared in step 1 while stirring 2 .2H 2 O and SbCl 3 solution and keep stirring for a while.

[0070] 4) The solution prepared in step 3) was heated to 200° C. and kept for 6 hours.

[0071] 5) The reaction mixture obtained in step 4) is separated and cleaned by centrifugation and suction filtration to obtain the anode catalyst.

Embodiment 3

[0072] Embodiment 3 (preparation of anode catalyst)

[0073] A method for preparing an anode catalyst, comprising the steps of:

[0074] 1) A certain amount of SnCl 2 .2H 2 O and SbCl 3 Dissolve in pure isopropanol to make a solution, the total concentration is 0.1mol / L, SnCl 2 .2H 2 O and SbCl 3 The molar ratio of the solution is 39:1, and the total volume of the solution is 1L.

[0075] 2) Prepare a saturated solution of NaOH with absolute ethanol.

[0076] 3) Titrate 60 mL of the saturated solution prepared in step 2) into the SnCl prepared in step 1 while stirring 2 .2H 2 O and SbCl 3 solution and keep stirring for a while.

[0077] 4) Heat the solution prepared in step 3) to 180° C. and keep it warm for 12 hours.

[0078] 5) The reaction mixture obtained in step 4) is separated and cleaned by centrifugation and suction filtration to obtain the anode catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com