Method for recovering graphite from waste cathode carbon blocks in electrolytic aluminium production

A technology of waste cathode carbon block and electrolytic aluminum, which is applied in the field of comprehensive utilization of solid waste resources, can solve problems affecting cement quality, etc., and achieve the effects of stable and reliable product quality, low production cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

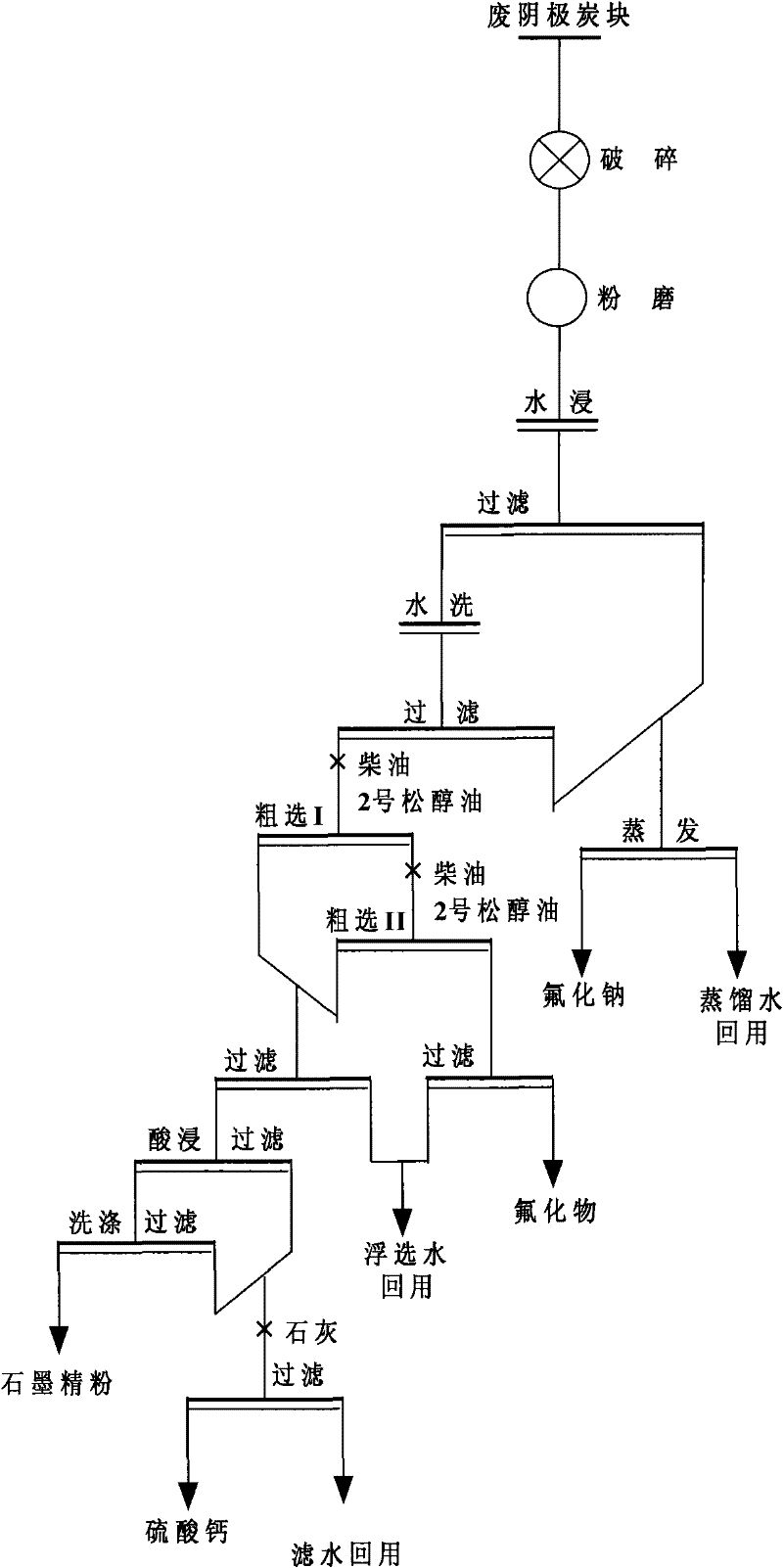

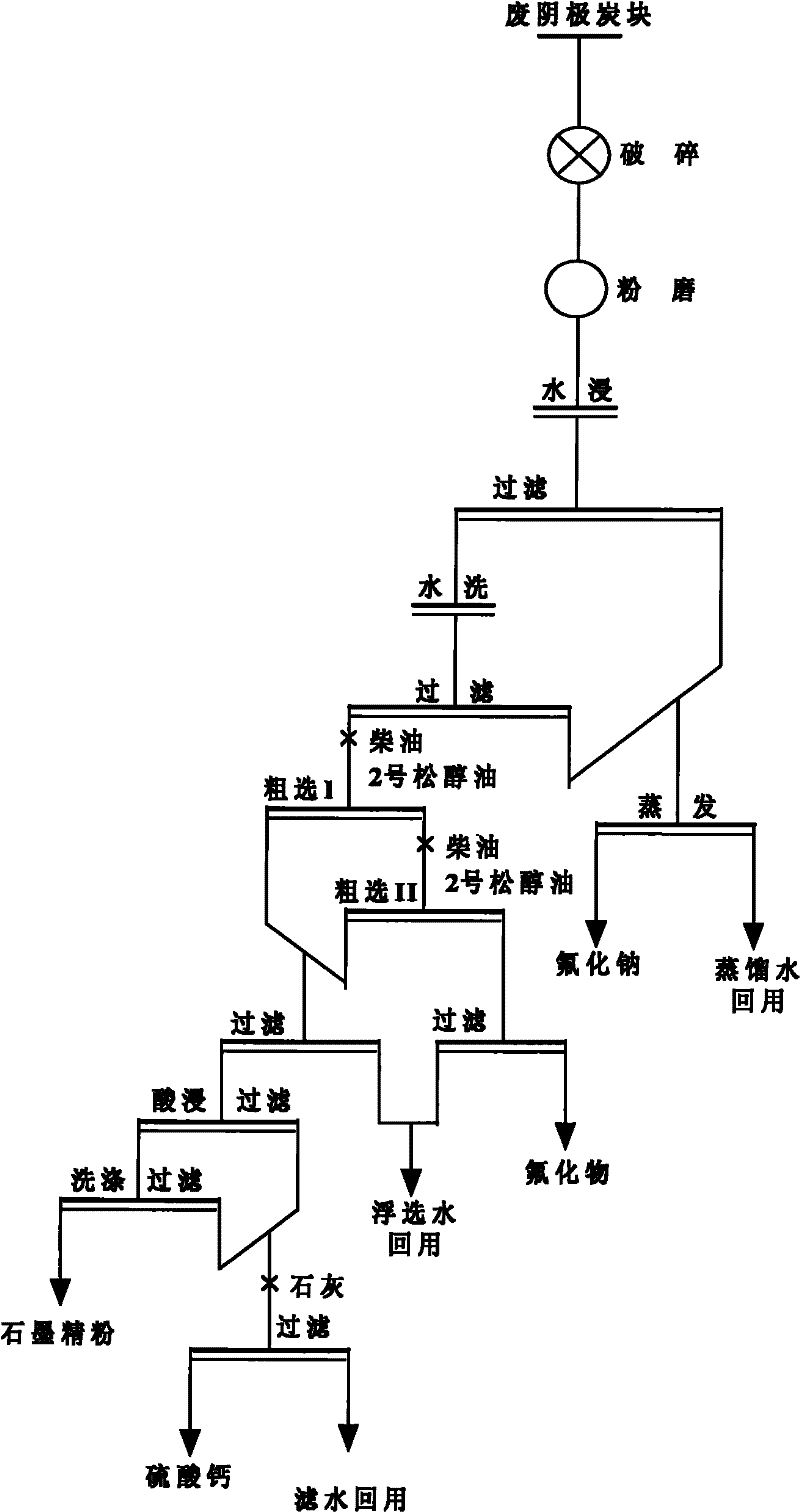

[0039] Such as figure 1 Shown, method of the present invention specifically comprises the following steps:

[0040] 1. Crushing and grinding, coarse crushing uses an impact crusher to crush the material to -200mm, enters the high-frequency vibration mill for fine crushing, and then enters the high-frequency vibration mill for grinding to -0.074mm, accounting for 70%.

[0041] 2. Water immersion: Add water to the ground waste cathode carbon block to adjust the slurry, and carry out water immersion. The water immersion concentration is 20%, and the water immersion temperature is 20°C. After stirring and leaching for 60 minutes, filter and wash, and the leaching solution is evaporated to obtain fluorine. Sodium chloride and distilled water are returned to the graphite recovery system.

[0042]3. Flotation, roughing I: add water to the filter cake of the waste cathode carbon block operation by water immersion to make a pulp with a mass concentration of 20%, add 400g / t of collecto...

Embodiment 2

[0048] Such as figure 1 Shown, method of the present invention specifically comprises the following steps:

[0049] 1. Crushing and grinding, coarse crushing uses a crusher to crush the material to -200mm, enters the high-frequency vibration mill for fine crushing, and then enters the high-frequency vibration mill for grinding to -0.074mm, accounting for 80%.

[0050] 2. Water immersion: Add water to the ground waste cathode carbon block to adjust the slurry, and carry out water immersion. The water immersion concentration is 50%, the water immersion temperature is 40°C, and the leaching is stirred and leached for 90 minutes, then filtered and washed, and the leaching solution is fluorinated by evaporation. Sodium, distilled water returns to the graphite recovery system.

[0051] 3. Flotation, roughing I: add water to the filter cake of the water immersion waste cathode carbon block operation to make a mass concentration of 30% ore pulp, add 200g / t of waste cathode carbon blo...

Embodiment 3

[0057] Such as figure 1 Shown, method of the present invention specifically comprises the following steps:

[0058] 1. Crushing and grinding, coarse crushing uses a crusher to crush the material to -200mm, enters the high-frequency vibration mill for fine crushing, and then enters the high-frequency vibration mill for grinding to -0.074mm, accounting for 60%.

[0059] 2. Water immersion: add water to the ground waste cathode carbon block to adjust the slurry, and carry out water immersion. The water immersion concentration is 10%, and the water immersion temperature is 60°C. After stirring and leaching for 30 minutes, filter and wash, and the leaching solution is evaporated to obtain fluorine. Sodium chloride and distilled water are returned to the graphite recovery system.

[0060] 3. Flotation, roughing I: add water to the filter cake of the water immersion waste cathode carbon block operation to make a pulp with a mass concentration of 10%, add 800g / t of collector diesel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com