Method and equipment for volume reduction treatment of low-radioactivity waste circular filters

A low-radioactivity filter technology, which is applied to the equipment and field for reducing the volume of low-radioactivity waste circular filters, can solve the problems of high disposal costs, large storage volume, and large storage space, and improve compression efficiency , to ensure cleanliness and improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

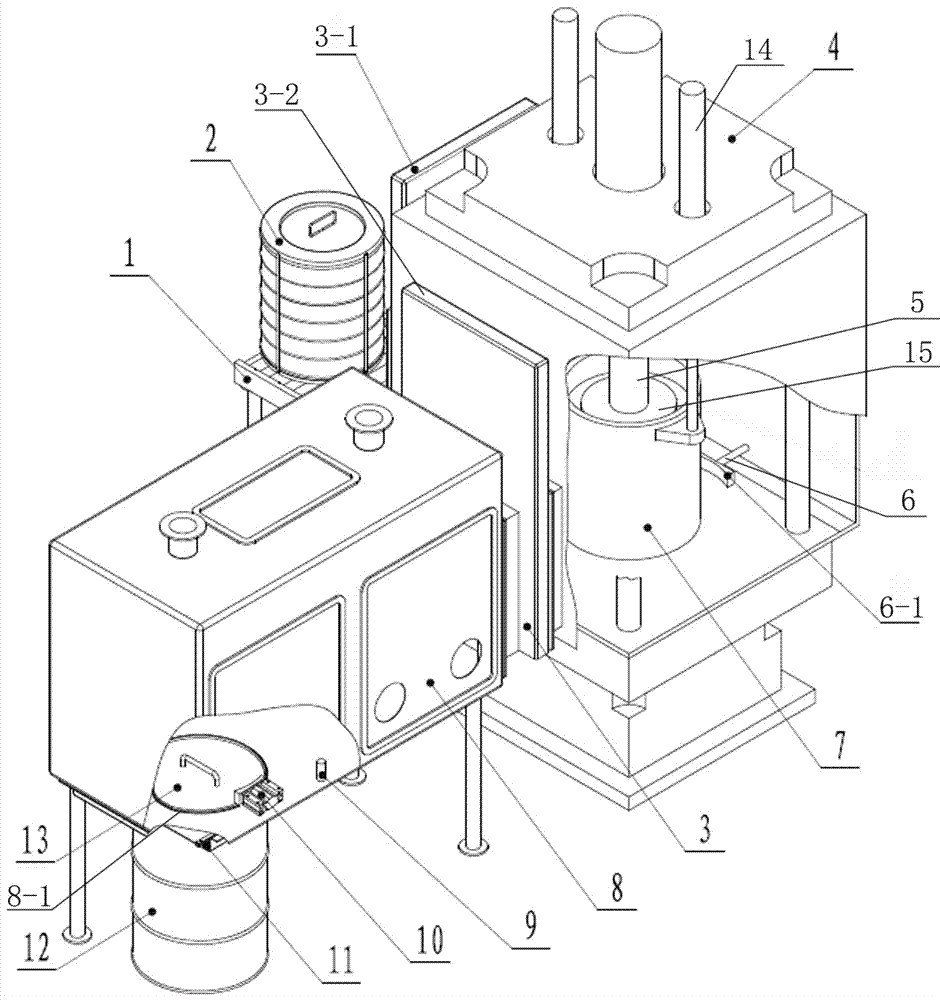

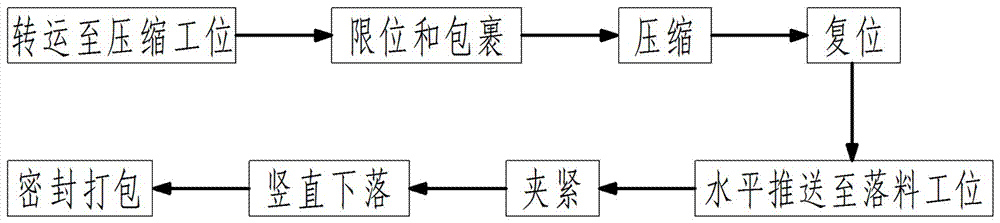

[0038] a. Transfer to the compression station: the waste circular filter 2 to be compressed with an external dimension of φ518mm×624mm is transferred to the compression station at the center of the working table at the bottom of the hydraulic press 4 via the roller table 1.

[0039] b. Position limit and package: close the isolation door I3-1 located at the entrance of the hydraulic machine 4, and the isolation door I3-1 cooperates with the isolation door II3-2 closed at the outlet of the hydraulic machine 4 to make the hollow inner cavity of the hydraulic machine 4 form an airtight space chamber; adjust the working pressure of the hydraulic press 4 to be 560KN; start the limit oil cylinder 14, the cylinder rod of the limit oil cylinder 14 moves down vertically, and the limit tube 7 connected to the output end of the limit oil cylinder 14 moves vertically down thereupon, and the The compressed waste circular filter 2 is limited and wrapped in the inner cavity of the limit cylin...

Embodiment 2

[0048] a. Transfer to the compression station: the waste round filter 2 to be compressed with an external dimension of φ518mm×335mm is transferred to the compression station at the center of the working table at the bottom of the hydraulic press 4 via the roller table 1.

[0049] b. Position limit and package: close the isolation door I3-1 located at the entrance of the hydraulic machine 4, and the isolation door I3-1 cooperates with the isolation door II3-2 closed at the outlet of the hydraulic machine 4 to make the hollow inner cavity of the hydraulic machine 4 form an airtight space cavity; adjust the working pressure of the hydraulic press 4 to be 360KN; start the limit oil cylinder 14, the cylinder rod of the limit oil cylinder 14 moves down vertically, and the limit tube 7 connected to the output end of the limit oil cylinder 14 moves vertically down thereupon, and the The compressed waste circular filter 2 is limited and wrapped in the inner cavity of the limit cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com