Preparation method of alpha-FeOOH/GAC catalyst and application thereof in degradation of nitrobenzene wastewater in supergravity field

A catalyst and high-gravity technology, applied in one or more application fields, can solve problems such as uneven crystal nucleation and growth, low ozone utilization rate, and difficult to control morphology, and achieve surface hydroxyl richness, surface area and surface hydroxyl density. The effect of improving and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

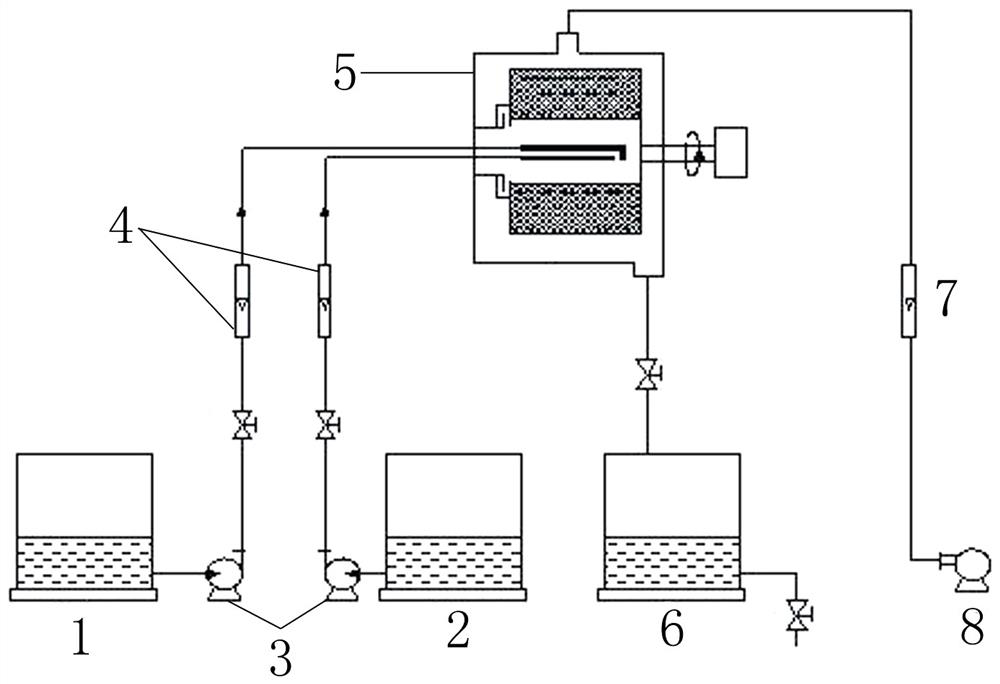

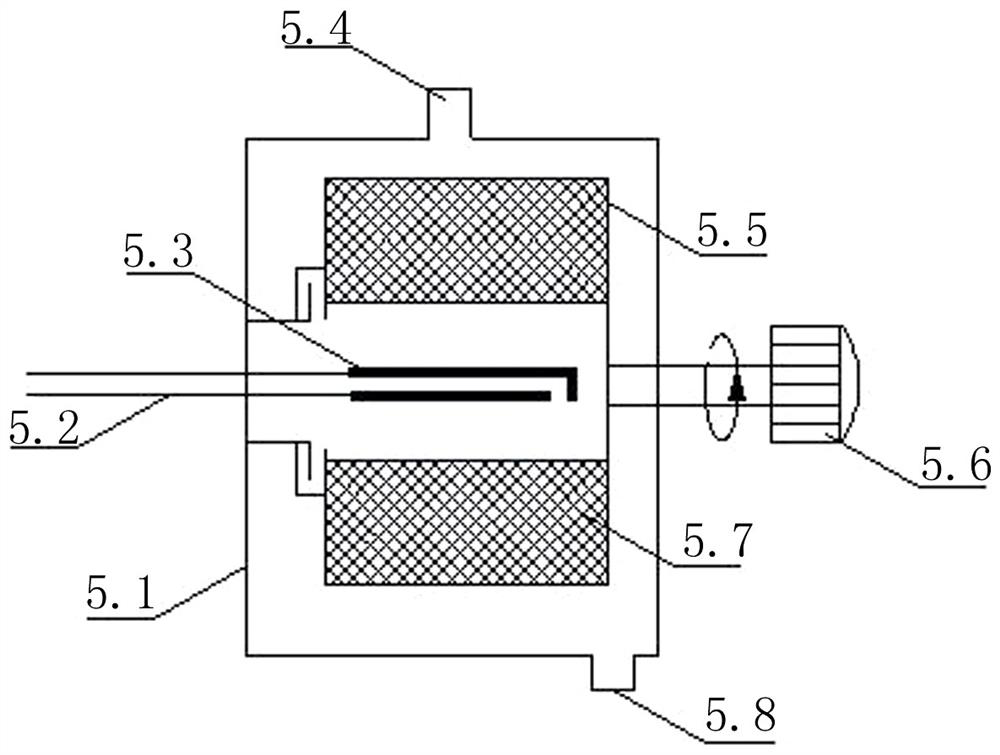

[0054] Example 1: Using figure 1 The flow shown is to prepare the supported α-FeOOH / GAC catalyst. Prepare FeSO with a molar ratio of 1:4 at 0.25 mol / L 4 solution and NaOH solution 1L each, filtered to remove particulate impurities, preheated to 25°C, and added to FeSO 4 solution tank 1 and NaOH solution tank 2.

[0055] It is sent into the impinging flow rotating packed bed 5 under the action of a centrifugal pump, the flow rate is 60 L / h, the rotation speed is set at 800 rpm, and air is introduced at a gas velocity of 10 L / h. Cycle the reaction until the potassium dichromate solution detects no Fe 2+ exist. The resulting FeOOH slurry was transferred to a beaker.

[0056] Spherical activated carbon particles with a diameter of 1-2mm were washed with ultrapure water, soaked in 0.1mol / L HCL solution for 24 hours, ultrasonically treated for 30 minutes, washed with deionized water until neutral, and dried overnight at 80°C. Add 10 g of activated carbon into the FeOOH slurry,...

Embodiment 2

[0057] Example 2: Using figure 1 The process shown is to prepare iron oxyhydroxide and supported activated carbon catalyst. Configure FeSO with a molar ratio of 2:1 at 0.25mol / L 4 solution and NaOH solution 1L each, filtered to remove particulate impurities, preheated to 25°C, and added to FeSO 4 solution tank 1 and NaOH solution tank 2. Under the action of the centrifugal pump 3, it is sent into the impinging flow rotating packed bed 5, the flow rate is 60 L / h, the speed is set at 400 rpm, and air is introduced at a gas velocity of 10 L / h. Cycle the reaction until the potassium dichromate solution detects no Fe 2+ exist. The resulting FeOOH slurry was transferred to a beaker. Spherical activated carbon particles with a diameter of 1-2mm were washed with ultrapure water, soaked in 0.1mol / L HCL solution for 24 hours, ultrasonically treated for 30 minutes, washed with deionized water until neutral, and dried overnight at 80°C. Add 10 g of activated carbon into the FeOOH sl...

Embodiment 3

[0058] Example 3: Using figure 1 The process shown is to prepare iron oxyhydroxide and supported activated carbon catalyst. Configure FeSO with a molar ratio of 1:1 at 0.25mol / L 4 Solution and NaOH solution 1L each, filter to remove particulate impurities, preheat to 25°C, add FeSO 4 solution tank 1 and NaOH solution tank 2. Under the action of the centrifugal pump 3, it is sent into the impinging flow rotating packed bed 5, the flow rate is 60 L / h, the speed is set at 400 rpm, and air is introduced at a gas velocity of 5 L / h. Cycle the reaction until the potassium dichromate solution detects no Fe 2+ exist. The resulting FeOOH slurry was transferred to a beaker. Spherical activated carbon particles with a diameter of 1-2mm were washed with ultrapure water, soaked in 0.1mol / L HCL solution for 24 hours, ultrasonically treated for 30 minutes, washed with deionized water until neutral, and dried overnight at 80°C. Add 10 g of activated carbon into the FeOOH slurry, stir and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com