A kind of polyester film and manufacturing method thereof

A technology of polyester film and manufacturing method, applied in the field of polyester film, can solve the problem that technical data is not disclosed, and achieve the effects of good barrier property, high chemical resistance and good shielding property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

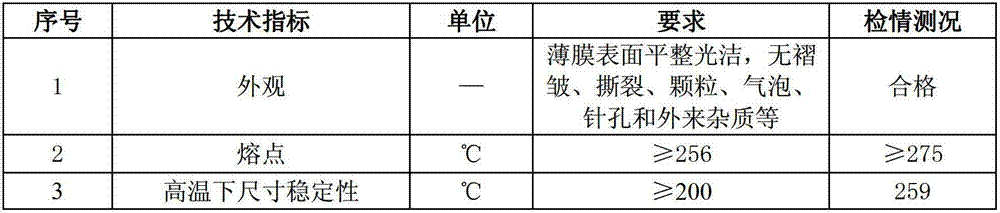

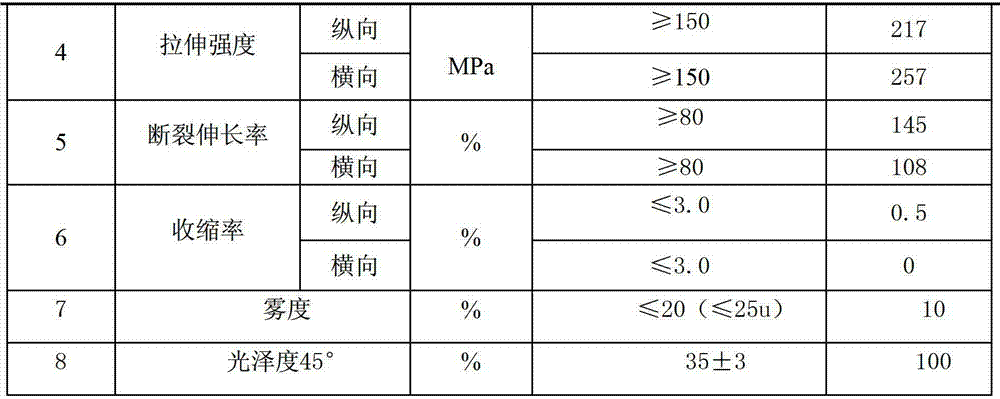

Examples

Embodiment 1

[0050] Embodiment 1 raw material preparation stage:

[0051] Mix 2.5kg of sodium bicarbonate, 3kg of silicon oxide, 2kg of manganese oxide and 2.5kg of phosphorus trioxide to make an inorganic mixture; then mix 557kg of isopropyl titanate, 400kg of ethanol, 35kg of pure water and 8kg The inorganic mixtures are mixed, hydrolyzed, filtered, washed, dried, pulverized and ground to obtain a titanium-based homogeneous composite catalyst.

[0052] After mixing 588kg of purified terephthalic acid, 393kg of ethylene glycol and 19kg of titanium-based homogeneous composite catalyst, first undergo an esterification reaction at a temperature of 210°C to 240°C and a pressure of 0.5MPa to 1MPa for 65min to 90min, and then After 100min to 110min of polycondensation at a temperature of 275°C to 280°C, a pressure of 140Pa to 160Pa, and a vacuum of 30Pa to 50Pa, film-grade polyester chips are formed;

[0053] Then mix 583kg of purified terephthalic acid, 389kg of ethylene glycol, 18kg of titan...

Embodiment 2

[0065] Embodiment 2 raw material preparation stage: the raw material prepared in this embodiment is the same as the raw material prepared in embodiment 1.

[0066] Film production stages:

[0067] (1) Pre-crystallize and dry 920kg film-grade polyester chips and 80kg polyester masterbatch chips. The temperature is controlled at 130°C to 185°C, and the drying time is 3.5 hours to 5 hours to control the water content of film-grade polyester chips Below 30ppm;

[0068] (2) After mixing 920kg of dried film-grade polyester chips with 80kg of polyester masterbatch chips, feed them into the extruder by metering. 275℃~288℃, the heating temperature of the melt tube is controlled at 275℃~288℃, and the temperature of the die head is controlled at 276℃;

[0069] (3) After the two raw materials of film-grade polyester chip and polyester masterbatch chip are melted and extruded, cast sheets are formed on the cooling roll, and the temperature of the cooling roll is controlled at 33°C;

[0...

Embodiment 3

[0074] Embodiment 3 Raw material preparation stage: the raw material prepared in this embodiment is the same as the raw material prepared in embodiment 1.

[0075] Film production stages:

[0076] (1) Pre-crystallize and dry 950kg film-grade polyester chips and 50kg polyester masterbatch chips. The temperature is controlled at 130°C to 185°C, and the drying time is 3.5 hours to 6 hours to control the water content of film-grade polyester chips Below 30ppm;

[0077] (2) After mixing 950kg of dried film-grade polyester chips with 50kg of polyester masterbatch chips, feed them into the extruder by metering. 275℃~295℃, the heating temperature of the melt tube is controlled at 275℃~295℃, and the temperature of the die head is controlled at 280℃;

[0078] (3) After the film-grade polyester chip and the polyester masterbatch chip are melted and extruded, they are cast on a cooling roll, and the temperature of the cooling roll is controlled at 35°C;

[0079] (4) The cast sheet is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com