Scrapped automobile disassembling production line and disassembling process

A technology for scrapped vehicles and production lines, which is applied in the direction of scrapped vehicles, motor vehicles, and solid waste removal. , to achieve the effect of resource reuse and compact process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

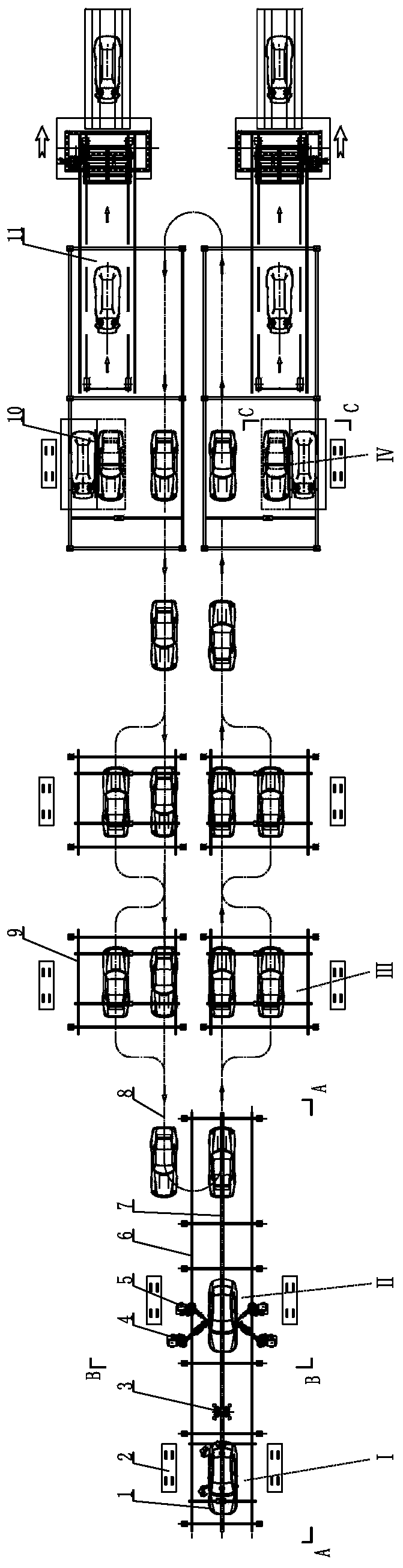

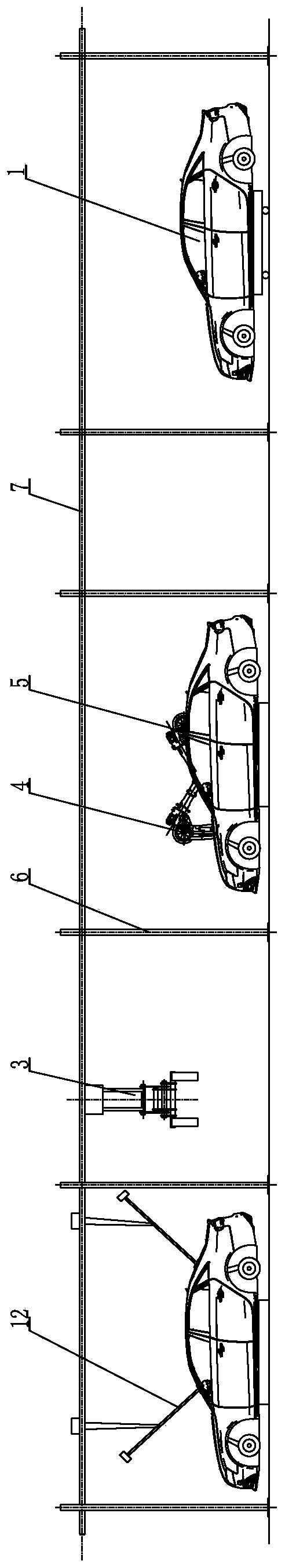

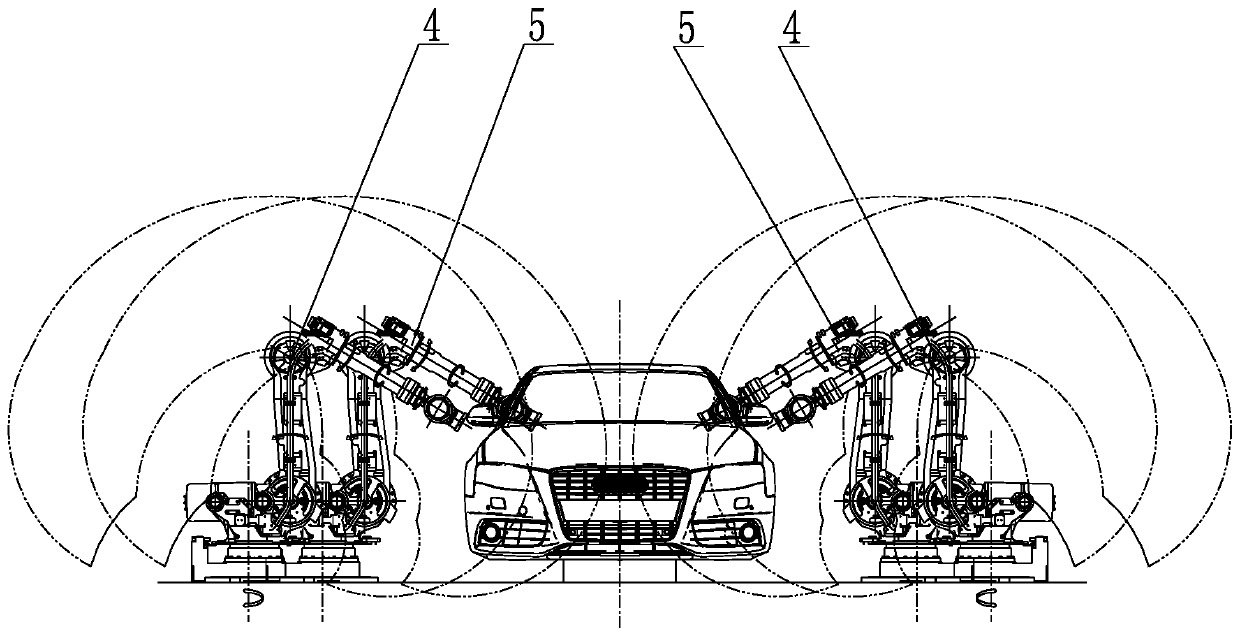

[0034] Such as Figure 1-Figure 4As shown, a scrapped automobile dismantling production line according to the present invention includes front and rear windshield dismantling station I, door dismantling station II, interior trim offline dismantling station III and chassis offline dismantling station vertically arranged sequentially along the production line. Dismantling station III; the front and rear glass dismantling station I is equipped with manipulator 12 and AGV transport trolley 2; from the front and rear glass dismantling station I to the interior offline dismantling station III, a mobile manipulator is installed on the production line upstream 3 is used to move scrapped cars 1 among the stations; the two sides of the door dismantling station II are respectively equipped with a car dismantling robot and an AGV transport trolley 2; the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com