Mining hydraulic support pin shaft automatic dismounting equipment and application thereof

A hydraulic support and automatic disassembly technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of consuming workers' physical strength and energy, low degree of automation, etc., saving labor, high efficiency and precision, and avoiding manual positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

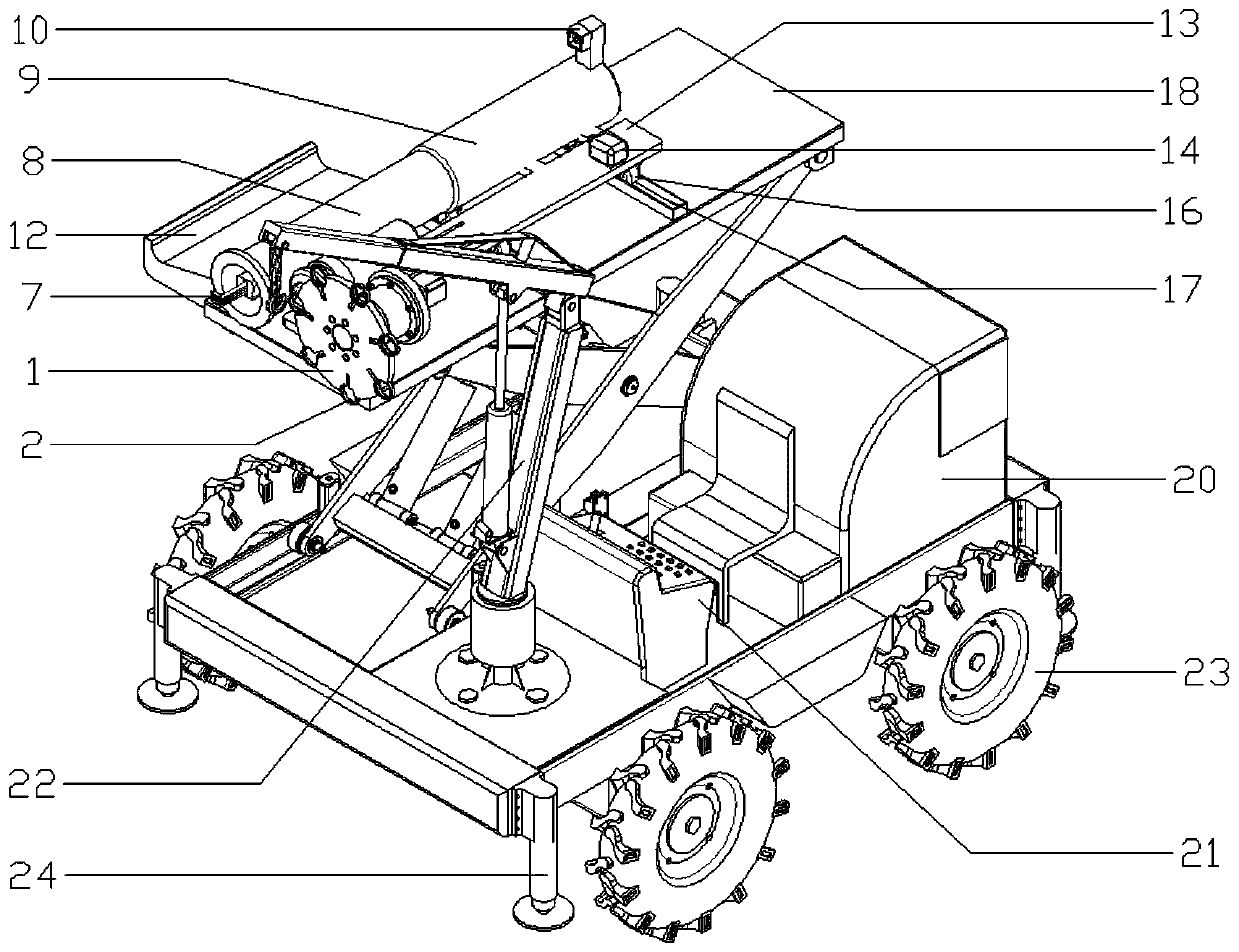

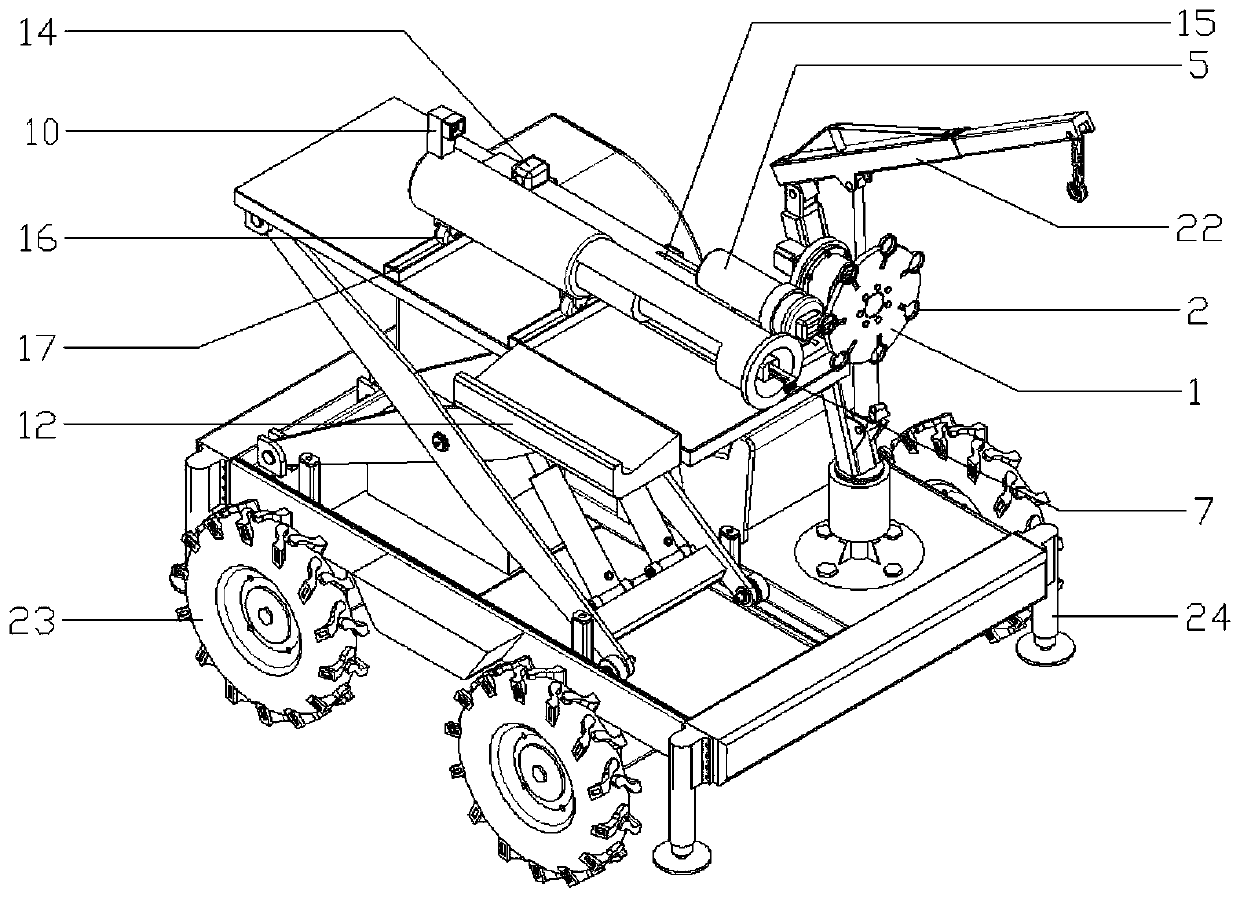

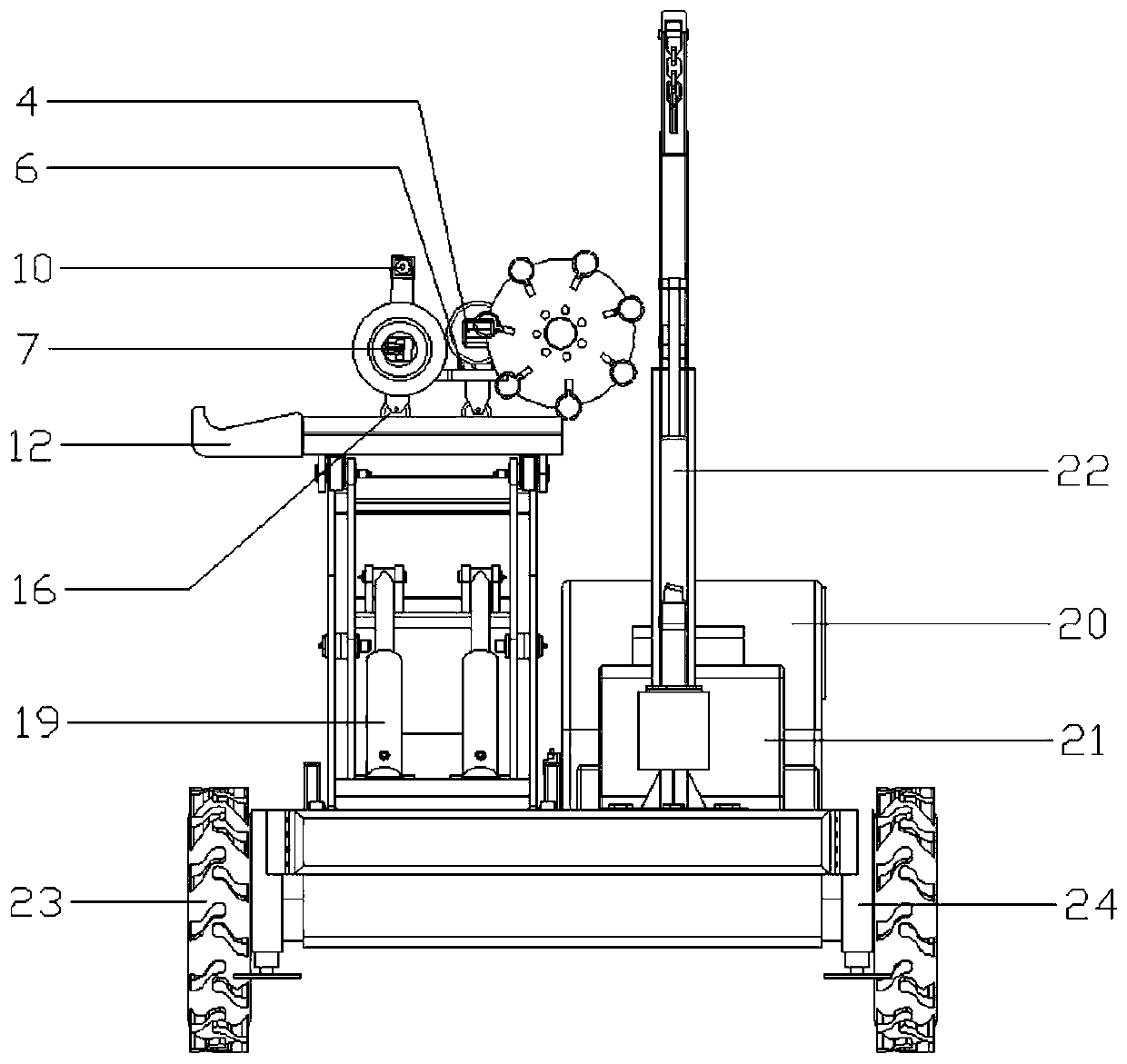

[0061] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a kind of equipment for automatically dismantling the pin shaft of the hydraulic support for mining, including a trolley, a hydraulic cylinder pin pulling device 9, a stud fixing device 5, a stud replacement device 1, a lifting platform 18, and a lifting device 22 and console 21;

[0062] The bottom of the lifting platform 18 is installed on the walking trolley through the scissors mechanism, and the scissors mechanism is driven by two lifting platform hydraulic cylinders 19 to stretch up or fold down, thereby driving the lifting platform 18 to lift. An I-shaped track 17 is installed on the top of the lifting platform 18, and a supporting plate 13 is welded on one side of the hydraulic cylinder pin pulling device 9, and the bottom of the hydraulic cylinder pin pulling device 9 and the supporting plate 13 are placed on the I-shaped track through an electric roller 16 17 on. The stud replacement dev...

Embodiment 2

[0077] An automatic detachment equipment for the pin shaft of a mine hydraulic support, the structure is as described in Embodiment 1, the difference is that a pin recovery plate 12 is connected to one side of the lifting platform 18 . The pin recovering plate 12 is located at one side of the sleeve opening 11, so that the disassembled pin can roll onto the pin recovering plate 12 by gravity through the sleeve opening 11 by itself.

Embodiment 3

[0079] A working method for the automatic disassembly equipment of hydraulic support pins for mining uses the technical solution described in Embodiment 2 to disassemble pins with threaded holes. The specific operation process is as follows:

[0080] (1) Move the walking trolley to one side of the hydraulic support that needs to be disassembled through the console 21;

[0081] (2) Adjust the lifting device 22 through the console 21, and use the hook of the lifting device 22 to fix the part of the hydraulic support to be dismantled, so as to avoid the safety accident caused by the parts falling after the pin shaft is pulled out;

[0082] (3) start the CCD camera by the console 21, collect the image information of the pin shaft to be dismantled at present, and transmit the image information to the console 21;

[0083] (4) The console 21 automatically adjusts the walking trolley, the lifting platform 18, and the supporting plate 13 according to the feedback image information to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com