Fixture for replacing automobile wheels

A wheel and fixture technology, which is applied in the direction of wheels, wheel assembly and disassembly equipment, tire installation, etc., can solve the problems of external thread damage, lack of lifting force, time-consuming and labor-intensive problems of threaded mounting columns, and achieve enhanced adaptability and convenient swinging out Or swinging insert, easy to move the effect of the fixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

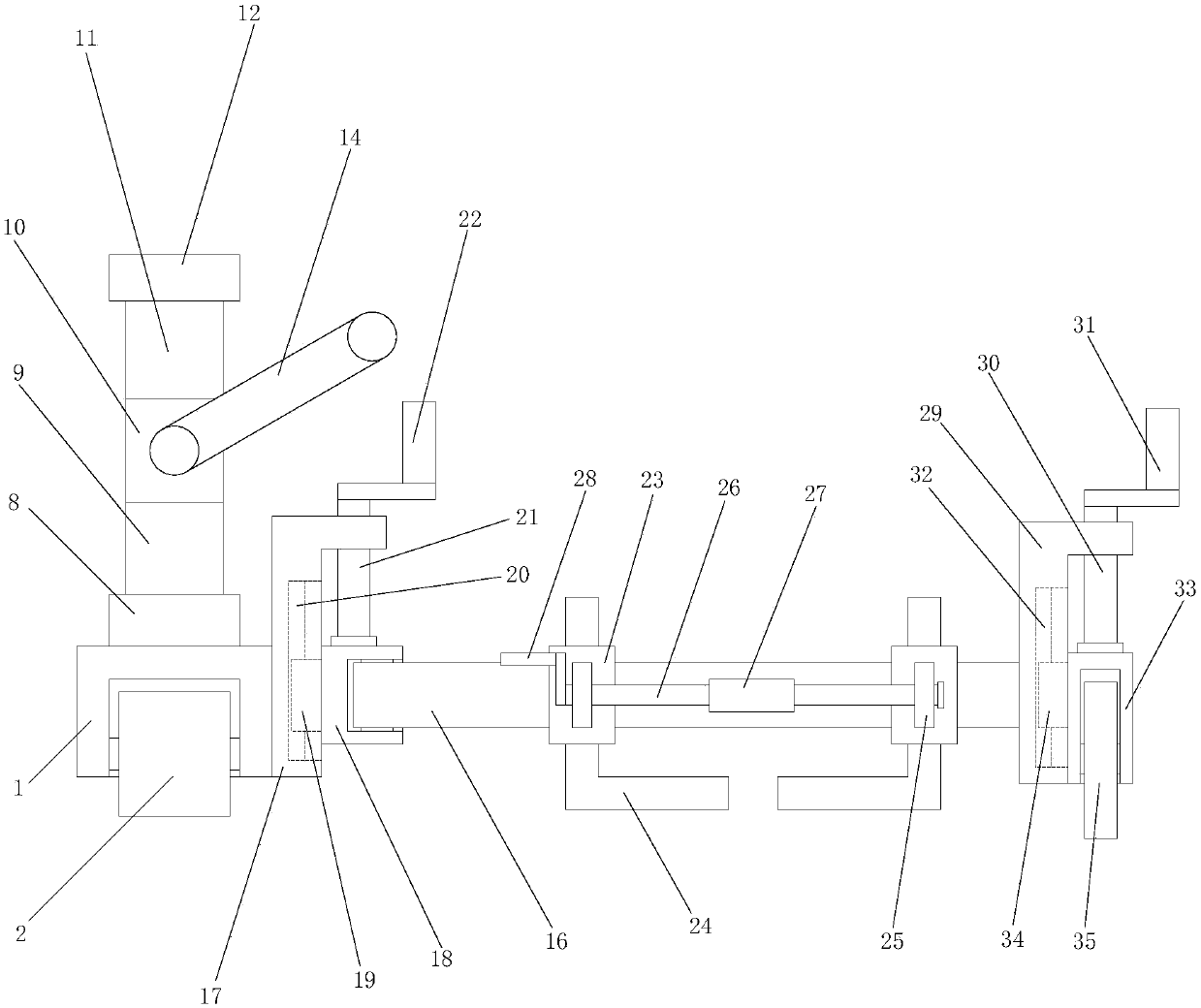

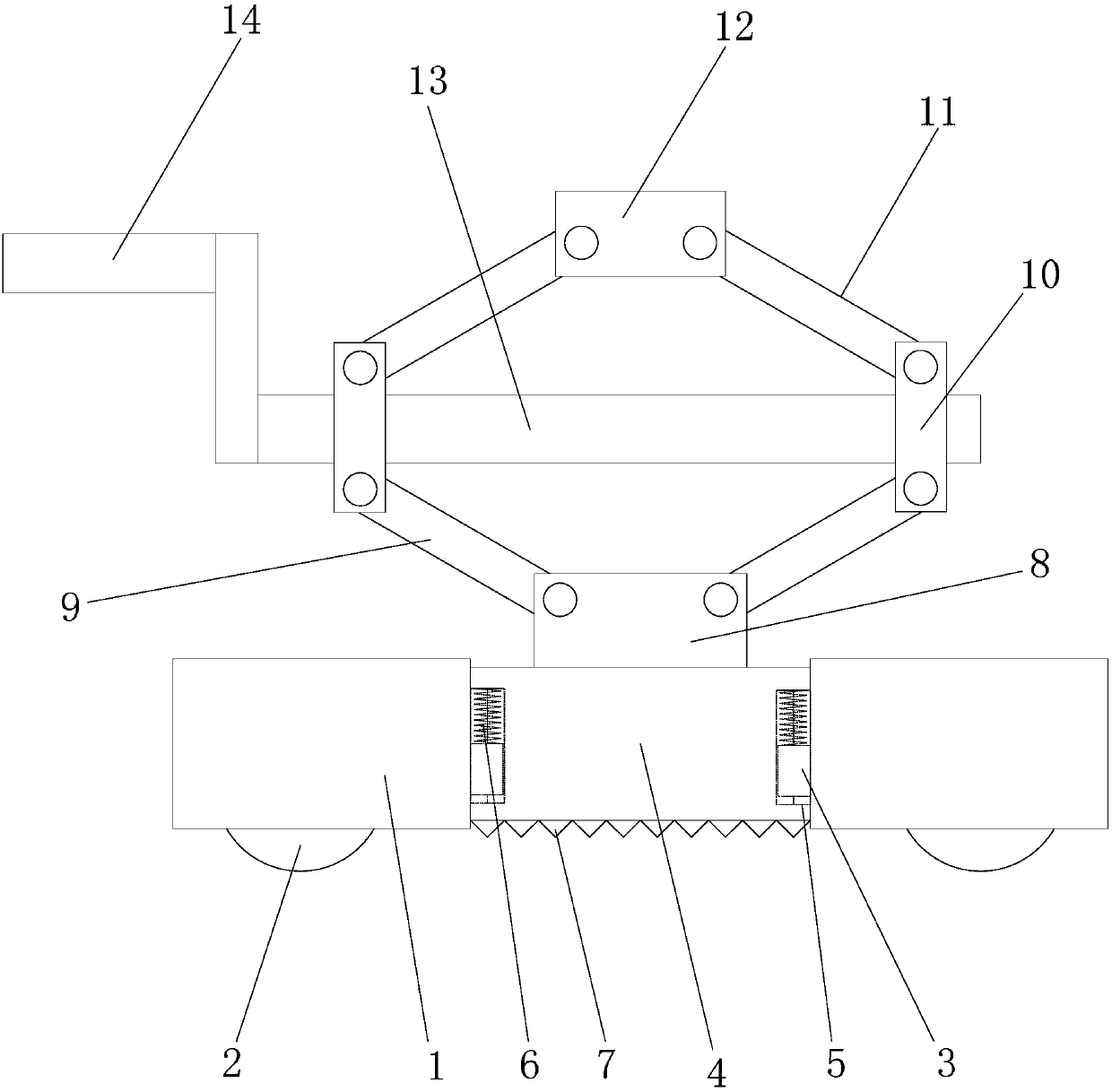

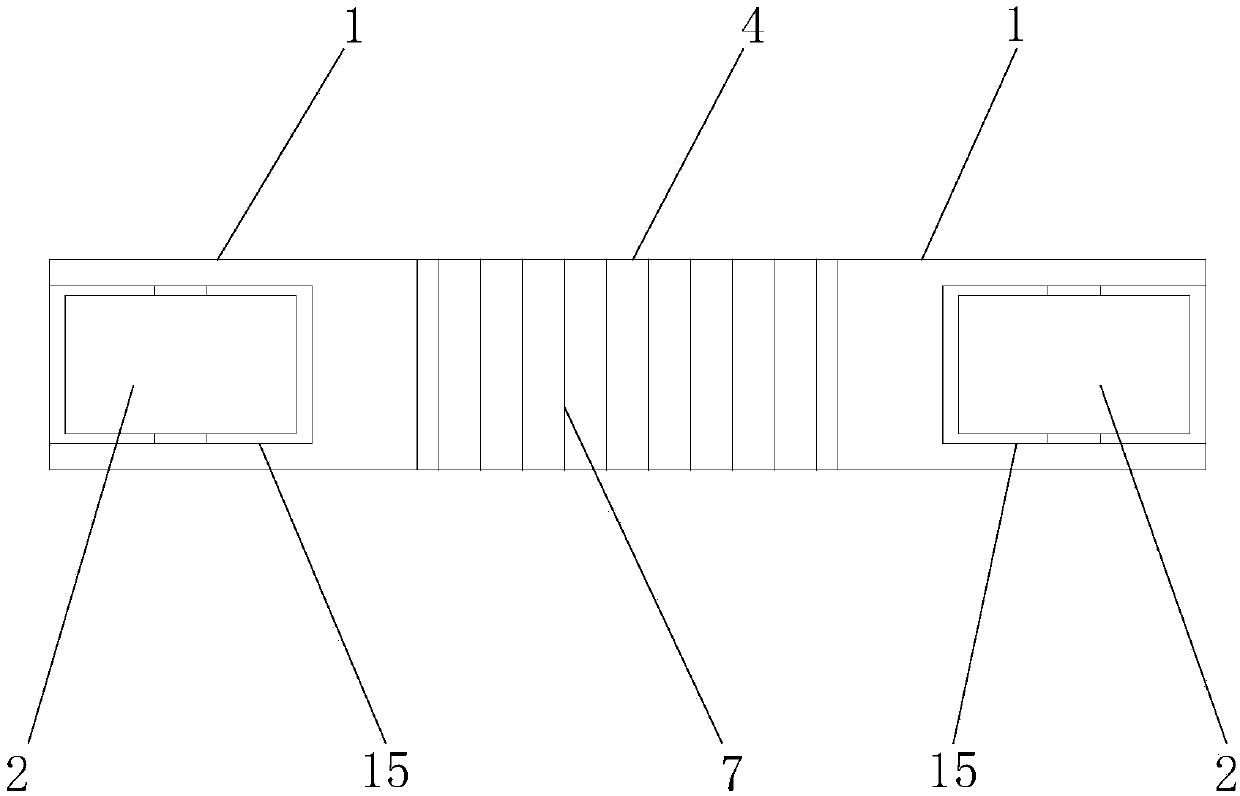

[0018] Such as Figure 1-3 As shown, the present invention provides a clamp for automobile wheel replacement including: two roller supports 1, lifting support base 4, left end lifter, right end lifter, support beam 16, right end support roller, left side clamp Holder, right side clamper and left end support 18; All vertically be provided with a lifting T-shaped chute 5 on the both ends sides of lifting support base 4; Lifting T-shaped slider 3; two roller supports 1 are installed on both ends of the lifting support base 4 respectively, and the lifting T-shaped slider 3 is embedded in the lifting T-shaped chute 5 on the corresponding side, and slides on the lifting T-shaped slide In the slot 5 and above the lifting T-shaped slide block 3, a support clip 6 is provided; a jack is provided on the lifting support seat 4; a roller mounting notch 15 is provided on the underside of the roller support 1; 15 is equipped with supporting rollers 2 rollingly; the left end lifter is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com